Novel gas-liquid separate production pipe column for underground drainage gas production of sulfur-containing gas well

A completion string, gas-liquid technology, applied in wellbore/well components, drill pipe, casing, etc., can solve problems such as hidden safety hazards, unsuitable for sulfur-containing gas wells, and no consideration of casing protection, etc., to avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] By the following specific examples to embodiments of the present invention is further illustrated done:

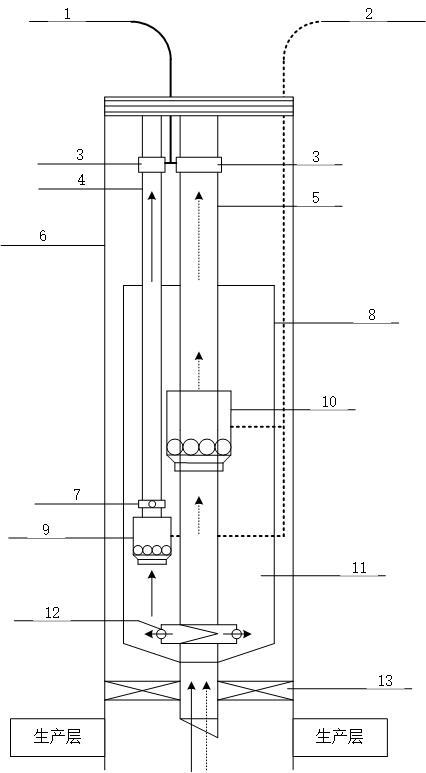

[0014] Append figure 1 It is shown, which can be used downhole sour gas-liquid drainage gas partial mining new column, which comprises a sleeve 6, the bottom of the cans into the sleeve 6 ESP system 8, vertically disposed sleeve 6 liquid discharge pipe 5 and the gas inside the tubing 4, the liquid 5 and gas discharge pipe 4 are mounted on the tubing downhole safety valve 3, valve 3 is connected to the ground equipment via a control line; canned submersible electric 8 pump system includes a gas-liquid separator 10, the ESP 10, ESP 9 and its accompanying components such as the automatic valve 7, and 9 of the electric submersible pump 10 through the ESP cable 2 and ground equipment connected.

[0015] Present invention provides a liquid drainage gas downhole sour gas for new methods and workflow sub-string is taken:

[0016] This downhole gas-liquid separator taken from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com