A hoisting platform for a high-rise industrial workshop and its hoisting method

A technology for hoisting platforms and industrial plants. It is applied in the directions of transportation and packaging, load hanging components, and building materials processing. It can solve problems such as the inability of elevators to be loaded and unloaded, so as to reduce the danger of manual operations, maintain integrity, and avoid hanging baskets. shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Combine below Figure 1 to Figure 6 , the present invention is further described:

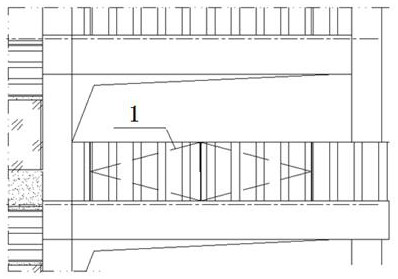

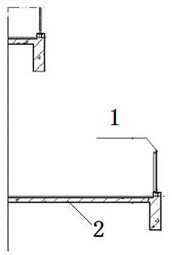

[0046] like figure 1 and figure 2 As shown, a hoisting platform of a high-rise industrial workshop is provided with a hoisting platform 2 protruding from the outer wall or flush with the outer wall on each layer of the outer wall. The openable structure is adopted, the hoisting platform fence 1 is opened during hoisting, and the goods are loaded and unloaded through the hoisting equipment, or the hoisting platform fence 1 is locked when not hoisted, so as to meet the safety protection effect and safety performance.

[0047] The hoisting platform guardrail 1 is a guardrail with pulleys, an openable glass door with a rainproof function, a rolling gate or a folding door.

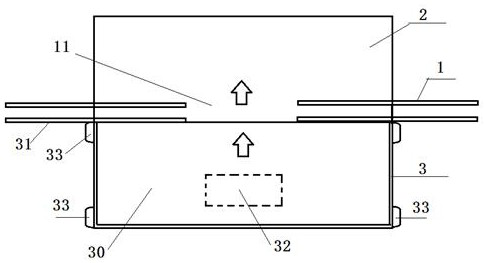

[0048] like image 3 As shown, the hoisting equipment is hoisted by the hoisting equipment, and the hoisting equipment includes a gondola 3, the gondola 3 has an openable railing 31, and the opening formed by the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com