Non-oriented silicon steel and production method thereof

A technology of oriented silicon steel and its production method, which is applied in the field of non-oriented silicon steel and its production, can solve the problems of non-uniform magnetic properties of non-oriented silicon steel coils and increase production costs, and achieve excellent magnetic properties, best magnetic properties, and consistent magnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

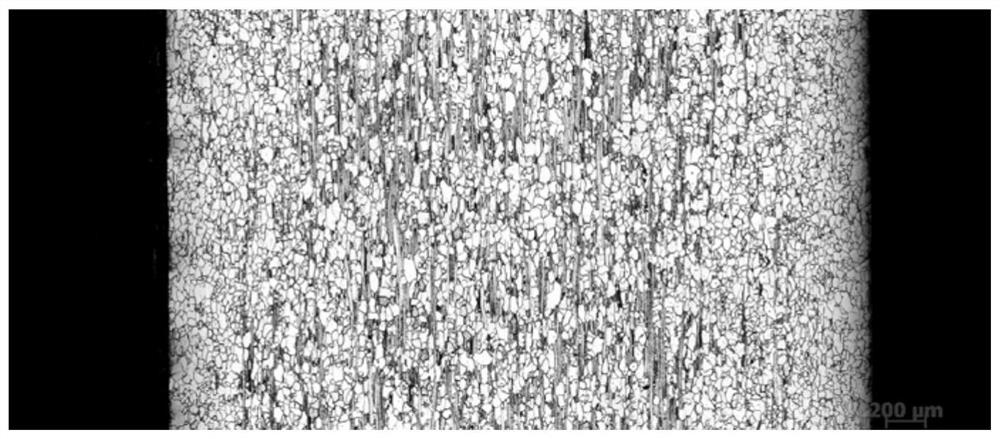

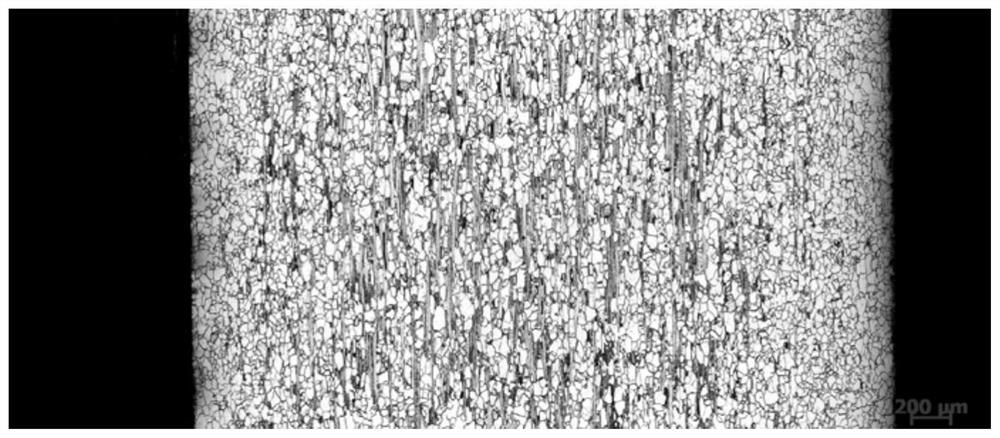

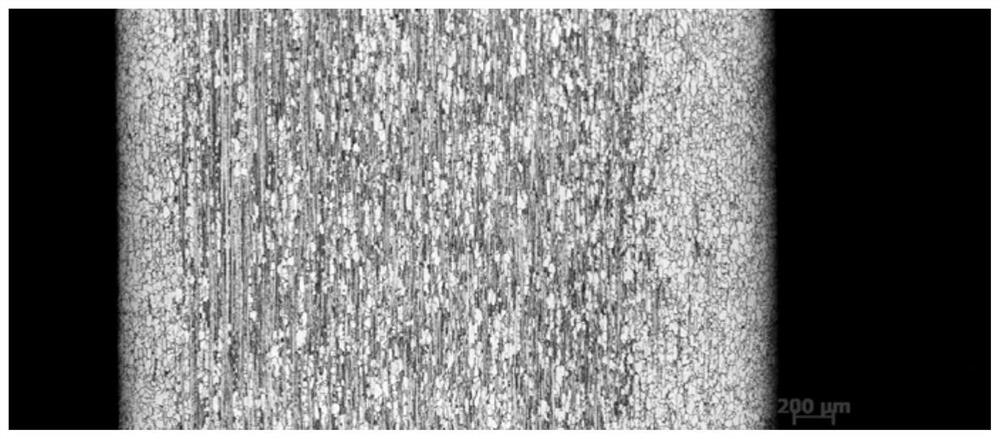

Image

Examples

Embodiment Construction

[0038] One embodiment of the present invention provides a non-oriented silicon steel and a production method of the non-oriented silicon steel. In the chemical composition of the non-oriented silicon steel, the Si content is 0.8-1.1% by mass percentage, and the Mn content is 0.2-0.4% by mass percentage. Prepared by continuous acid rolling, finished annealing, cooling, coating and finishing. That is, the production method includes the steps of steelmaking, slab casting, hot rolling, normalization, acid continuous rolling, finished product annealing, cooling, coating and finishing in sequence. The production method is described in detail below in accordance with the following steps.

[0039] Step 1) Steelmaking is carried out according to the Si mass percentage of 0.8-1.1% and the Mn mass percentage of 0.2-0.4% in the chemical composition, and Sn and Sb are not added during the steel-making process, and a cast slab is prepared.

[0040] This step 1 is the steelmaking process a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com