A kind of antimony composite flame retardant and preparation method thereof

An antimony-based flame retardant and composite technology, applied in the field of flame retardants, can solve the problems affecting the physical and mechanical properties, optical properties, limited use range, uneven dispersion and other problems of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

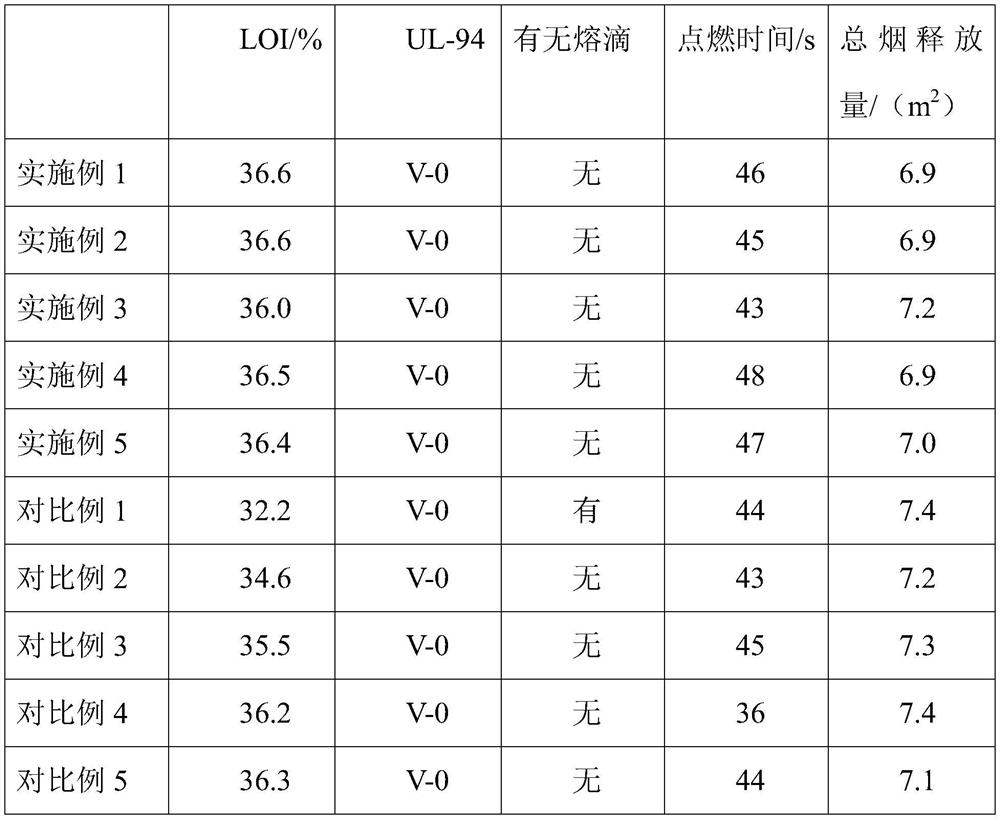

Examples

Embodiment 1

[0025] An antimony-based composite flame retardant, whose exterior is coated with oleic acid, and whose interior is composed of nanometer antimony trioxide, aluminum diethylphosphinate, and Co-MOFs.

[0026] Among them, the mass ratio of nano antimony trioxide, aluminum diethylphosphinate, and Co-MOFs is 2.5:1:6.

[0027] The preparation method of Co-MOFs is as follows:

[0028] Will Co(NO 3 ) 2 1. Add terephthalic acid into a sufficient amount of DMF / ethanol / water solution according to the mass ratio of 1.6:1 (the volume ratio of DMF, ethanol, and water is 3:1:1), first 400W ultrasonic dispersion for 30min, then mechanical stirring at room temperature 200r / min for 2h, The reaction solution was transferred to a sealed autoclave, heated to 165°C and reacted for 45 hours, the reaction solution was cooled and filtered with suction, the solid was washed three times with absolute ethanol and then vacuum-dried at 60°C.

[0029] The preparation method of antimony series composite ...

Embodiment 2

[0032] An antimony-based composite flame retardant, whose exterior is coated with oleic acid, and whose interior is composed of nanometer antimony trioxide, aluminum methylcyclohexylphosphinate, and Co-MOFs.

[0033] Among them, the mass ratio of nanometer antimony trioxide, aluminum methylcyclohexylphosphinate, and Co-MOFs is 2:1:5.

[0034] The preparation method of Co-MOFs is as follows:

[0035] Will Co(NO 3 ) 2 1. Add terephthalic acid into a sufficient amount of DMF / ethanol / water solution according to the mass ratio of 1.6:1 (the volume ratio of DMF, ethanol, and water is 3:1:1), first 400W ultrasonic dispersion for 30min, then mechanical stirring at room temperature 200r / min for 2h, The reaction solution was transferred to a sealed autoclave, heated to 165°C and reacted for 45 hours, the reaction solution was cooled and filtered with suction, the solid was washed three times with absolute ethanol and then vacuum-dried at 60°C.

[0036] The preparation method of antim...

Embodiment 3

[0039] An antimony-based composite flame retardant, whose exterior is coated with oleic acid, and whose interior is composed of nano antimony trioxide, aluminum diethylphosphinate, and Ni-MOFs.

[0040] Among them, the mass ratio of nano antimony trioxide, aluminum diethylphosphinate and Ni-MOFs is 2.5:1:8.

[0041] The preparation method of Ni-MOFs is as follows:

[0042] Ni(NO 3 ) 2 1. Add terephthalic acid into a sufficient amount of DMF / ethanol / water solution according to the mass ratio of 1.6:1 (the volume ratio of DMF, ethanol, and water is 3:1:1), first 400W ultrasonic dispersion for 30min, then mechanical stirring at room temperature 200r / min for 2h, The reaction solution was transferred to a sealed autoclave, heated to 165°C and reacted for 45 hours, the reaction solution was cooled and filtered with suction, the solid was washed three times with absolute ethanol and then vacuum-dried at 60°C.

[0043] The preparation method of antimony series composite flame retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com