Radial magnetic pole damping cage structure of generator rotor

A generator rotor and rotor magnetic pole technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electrical components, etc., can solve high production cost, complex processing technology, production technology and installation work ask advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

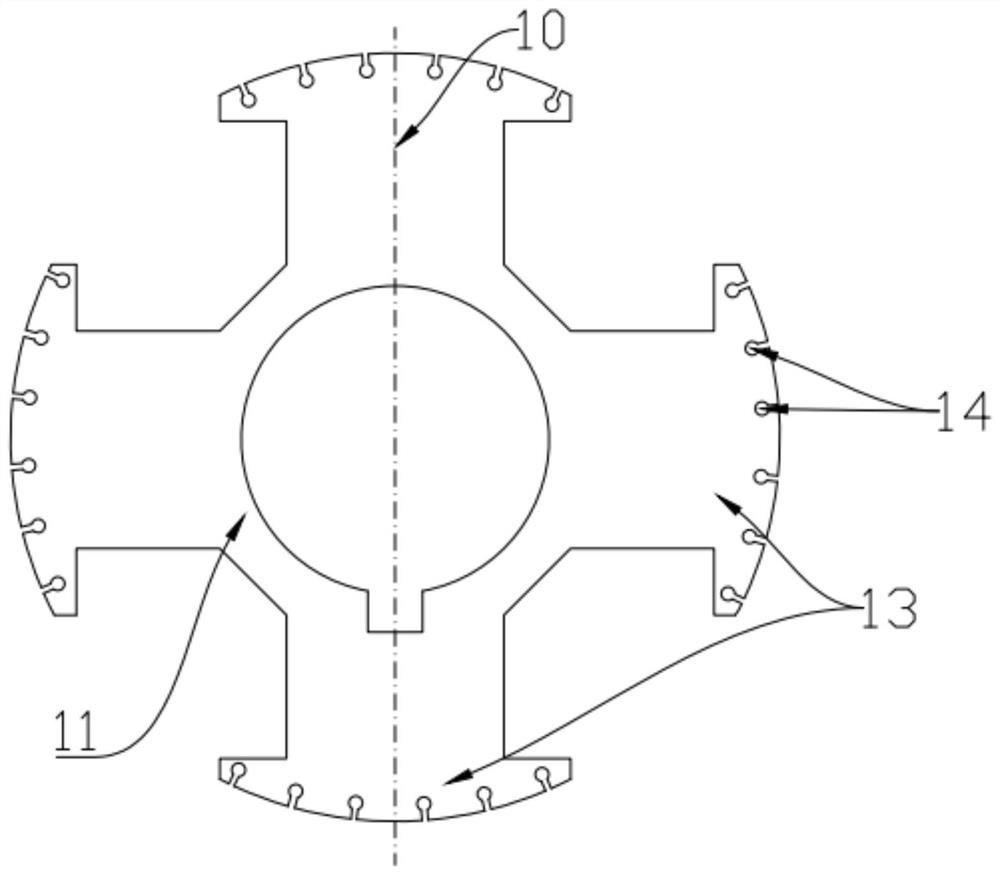

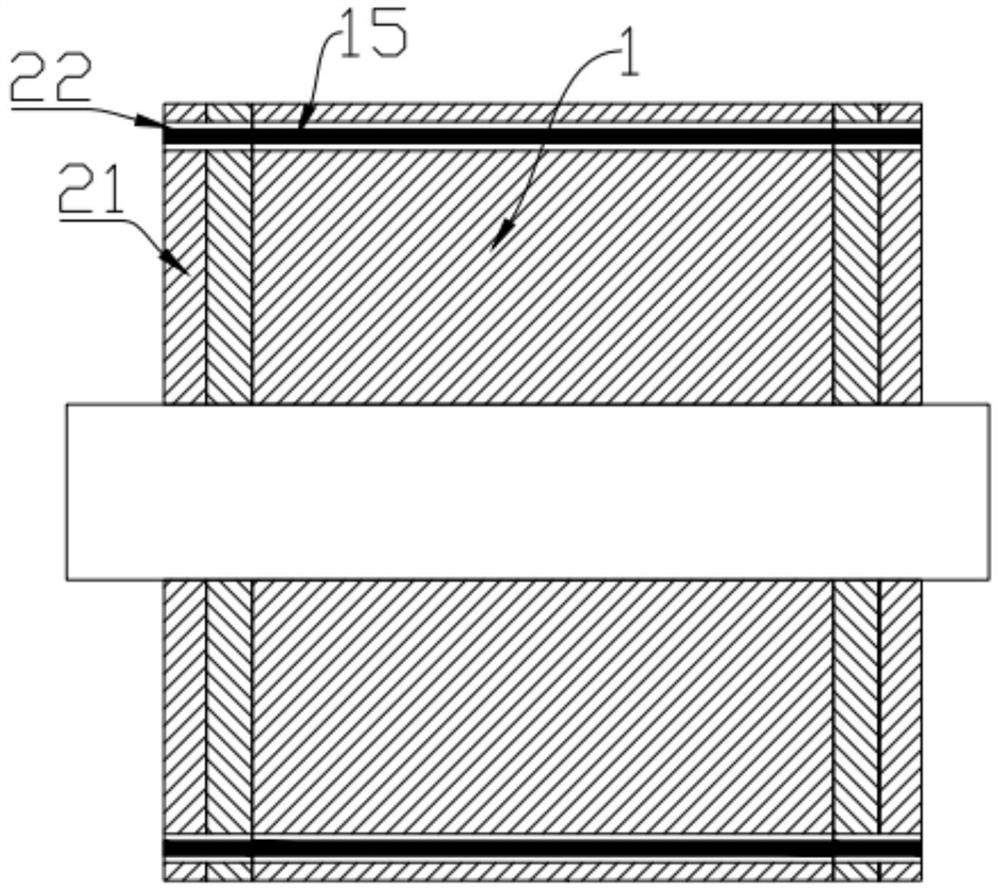

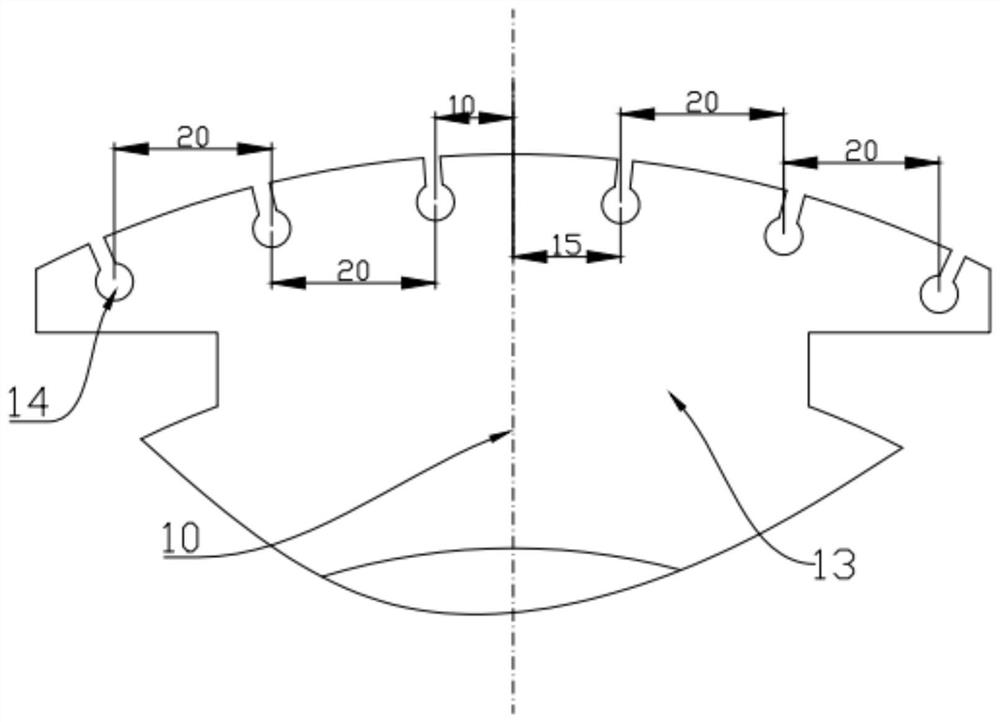

[0017] Such as figure 1 and figure 2 As shown, the technical solution of the present invention is a generator rotor radial pole damping cage structure, including two damping rings 21 placed at both ends of the rotor 1 and several damping rings 21 that pass through the rotor core 1 and are electrically connected to the two damping rings 21. Guide bar 15. The rotor 1 includes a rotor core 11 , a rotor pole 13 and several damping holes 14 arranged on the rotor pole 13 . The damping hole 14 is a straight slot damping hole whose central axis is parallel to the axis of the rotor core 1 . The damping holes 14 on the same rotor pole 13 are arranged at asymmetric intervals, that is, the pitches of the damping holes (the distance between two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com