Automatic quantitative liquid material feeding device and use method thereof

A feeding device and material technology, applied in fixed-capacity gas storage tanks, container discharge methods, gas treatment applications, etc., can solve the problems of complex automatic feeding mechanism, cost and food safety pressure, and insufficient flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

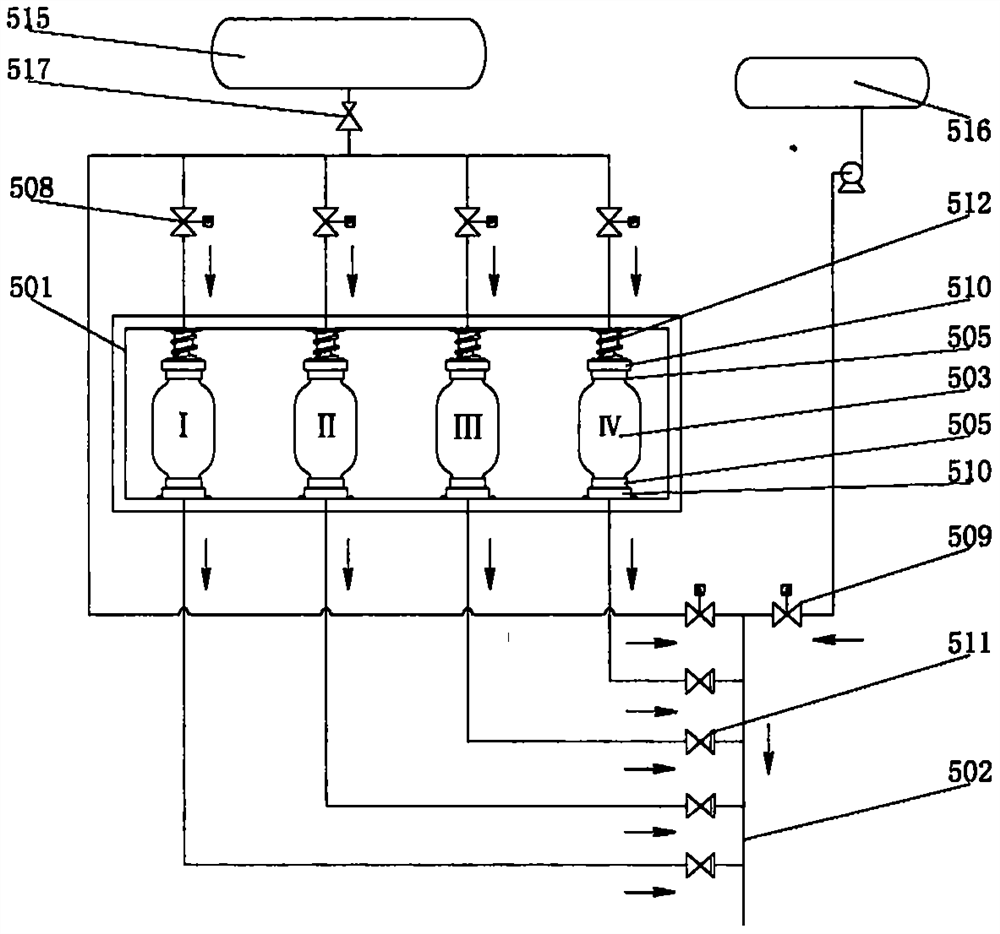

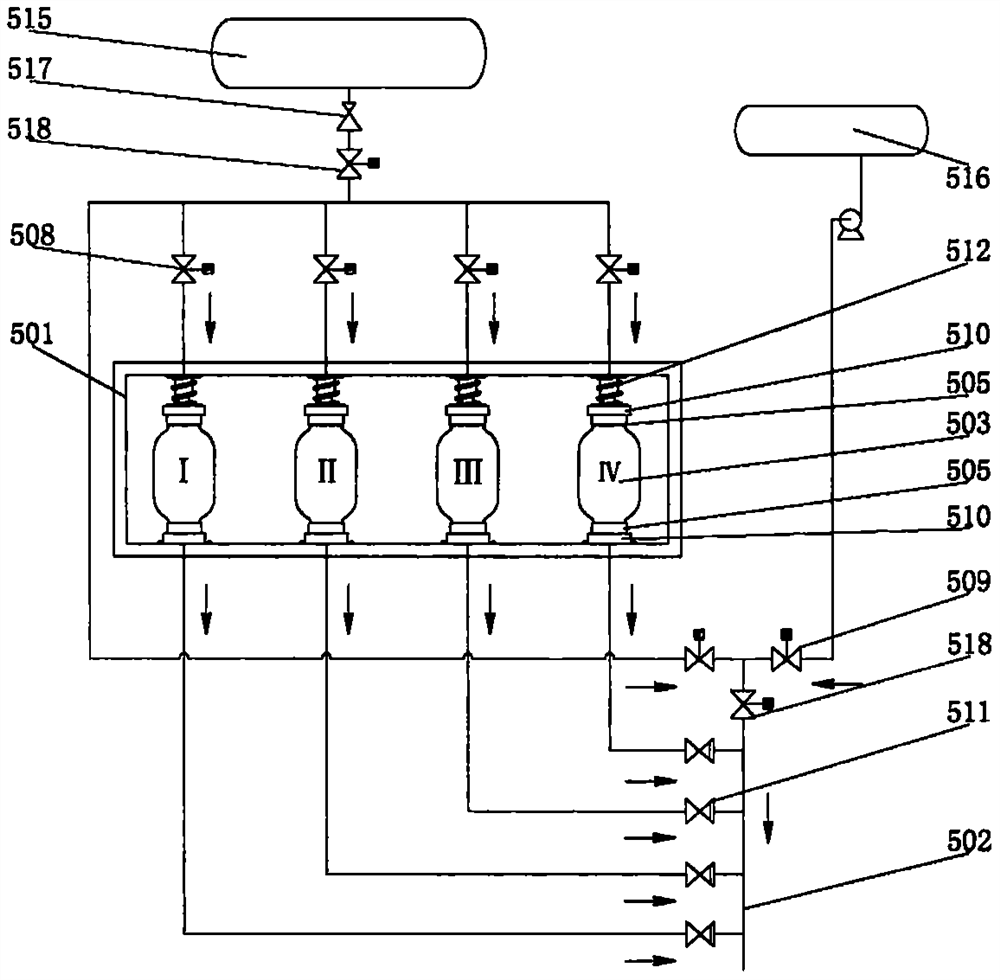

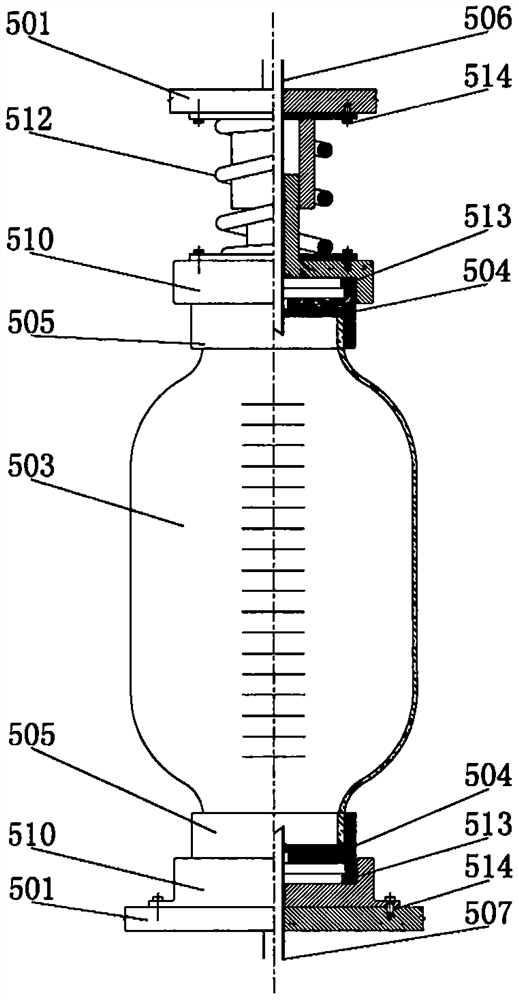

[0037] combine Figure 1 to Figure 3 As shown, a liquid material automatic quantitative feeding device applicable to the embodiment of the present invention includes: a feeding assembly fixing frame 501, which is used to fix the feeding assembly (not labeled); a compressed air storage tank 515, connected with a constant pressure valve 517, Used to deliver compressed air with constant pressure to the feeding assembly; at least one feeding pipe 502; at least one feeding assembly, wherein the feeding assembly includes: a container (unlabeled), which is used to accommodate liquid materials; The pierci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com