Lamp mounting assembly for hidden frame glass curtain wall

A technology for installation of hidden frame glass curtain walls and lamps, which is applied to parts, walls, and building components of lighting devices, and can solve the problems of poor integration of glass curtain walls and lighting equipment, safety issues, and damage to the aesthetics of glass curtain walls, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

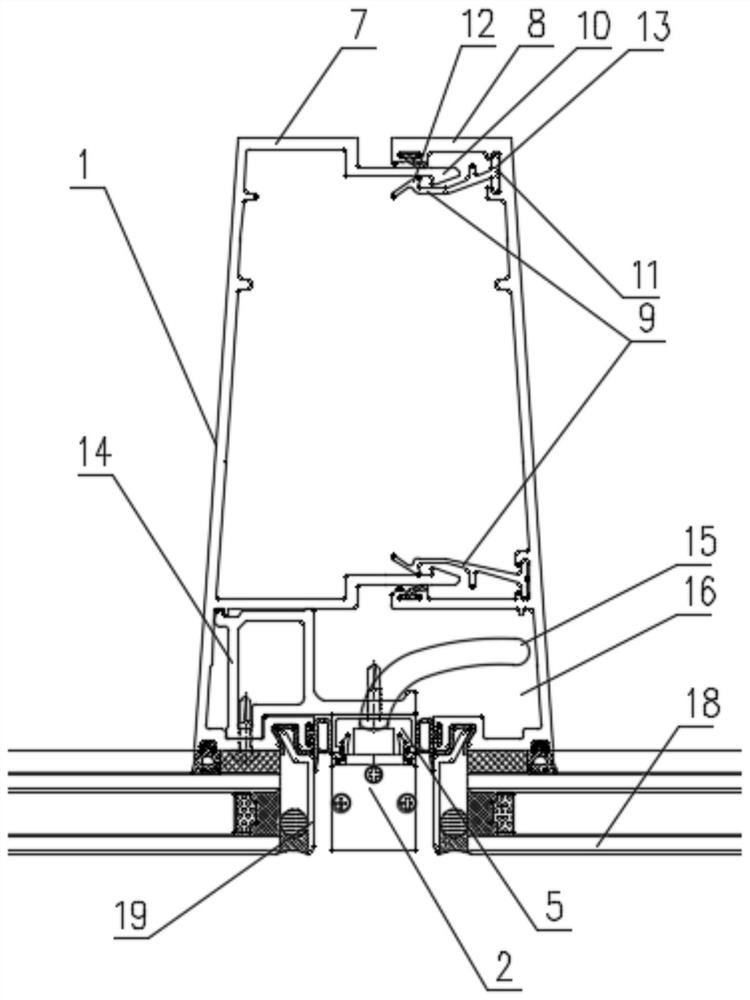

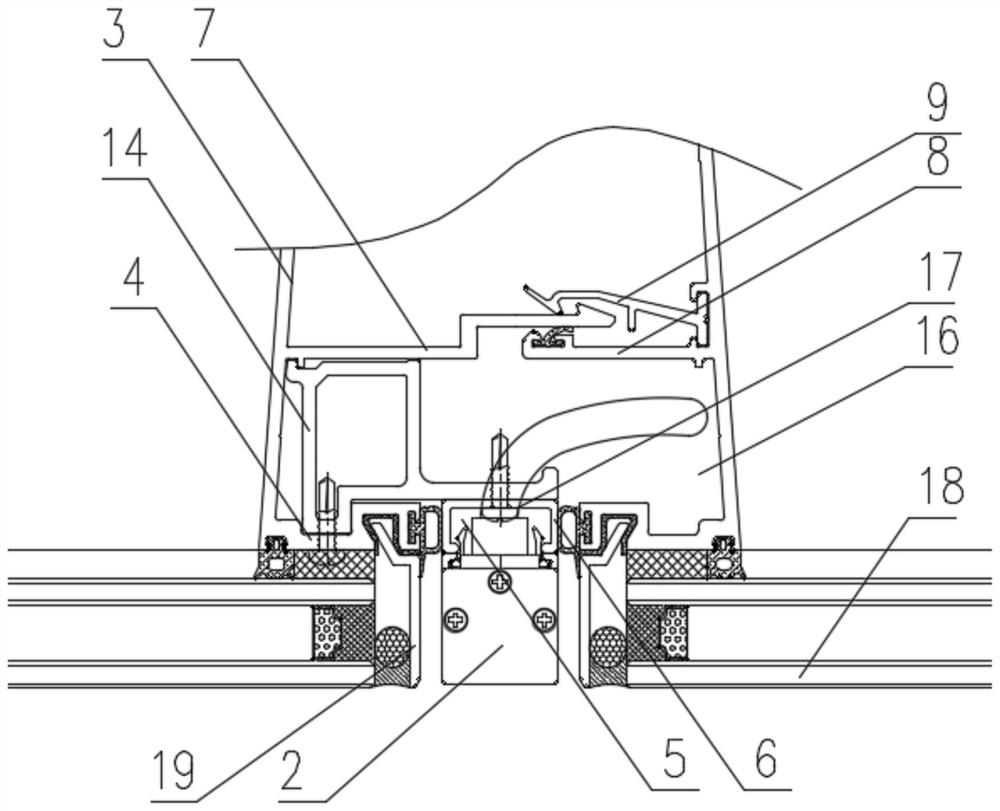

[0028] Such as figure 1 with figure 2 Shown:

[0029] A hidden frame glass curtain wall lamp installation assembly, including a column 1 and a lamp body 2, the column 1 is made of two oppositely arranged unit plates 3 of aluminum alloy material, the cross section of the column 1 is a trapezoidal structure, and the cross section of the column 1 is The width gradually increases along the direction close to the curtain wall glass 18 .

[0030] The width of the front end of the column 1 of the present invention is slightly wider than that of the traditional hidden frame glass curtain wall, but since the aluminum alloy column adopts the trapezoidal design, the lighting effect of the glass curtain wall does not change significantly.

[0031] A baffle 4 is integrally formed on the inner side of the two unit panels 3 close to the end of the curtain wall glass. The baffle 4 can be made into a structure integrally formed with the unit panel 3, and the gap between two adjacent baffles...

Embodiment 2

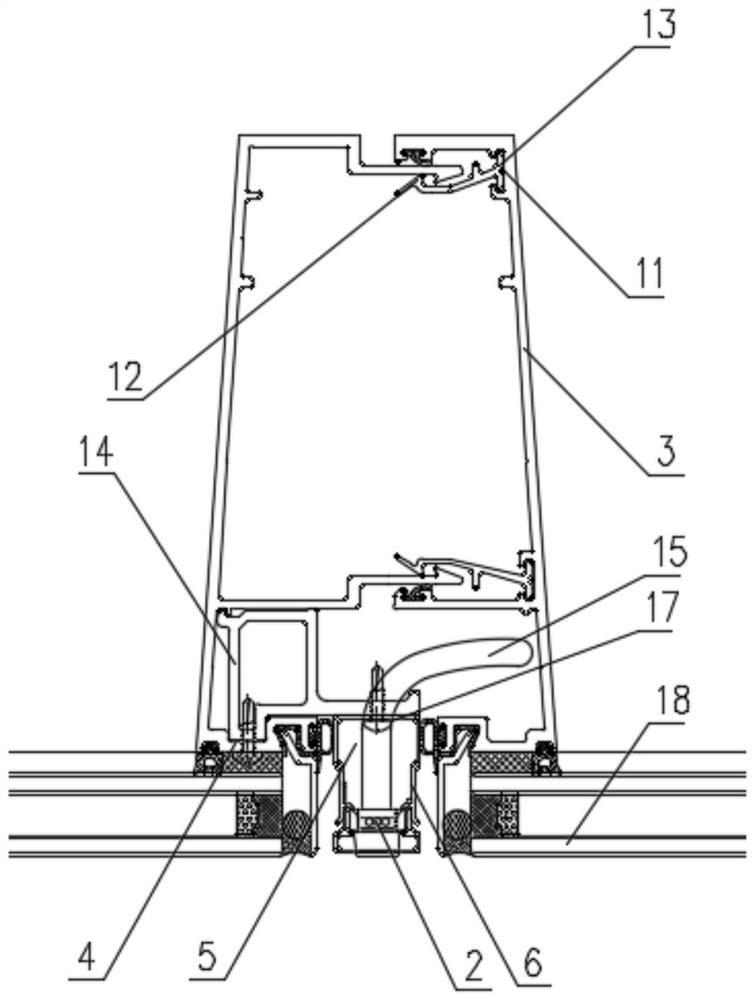

[0040] Such as image 3 with Figure 4As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, a 20-25 mm lamp installation groove 5 for installing lamps is reserved between the two unit plates 3 1. Fix the lamp installation attachment frame 6 in the lamp installation groove 5, and the lamp body snap-connected with the lamp installation attachment frame 6 is a point light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com