Device capable of improving aluminum oxidation surface quality

A technology of surface quality and aluminum oxidation, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of smaller airbags, lower surface quality of workpieces, and reduced gas throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] Specific embodiment one: please refer to Figure 1-3 A device that can improve the surface quality of aluminum oxidation, including a compound chamber 1, a heating plate 2, a coating chamber 5 and a workpiece 6.

[0052] The coating chamber 5 is located at the upper end of the compound chamber 1, and the workpiece 6 is located in the coating chamber 5.

[0053] The heating plate 2 is located in the compound chamber 1, and the heating plate 2 makes the temperature in the compound chamber 1 higher than 700°C.

[0054] An aluminum air pipe 4 , an oxygen pipe 7 and a nitrogen pipe 8 are connected through the outer wall of the compound chamber 1 .

[0055] The aluminum gas pipe 4 provides gaseous metal aluminum for the compound chamber 1 .

[0056] The oxygen pipe 7 provides oxygen for the compound chamber 1 .

[0057] The nitrogen pipe 8 provides nitrogen for the compound chamber 1 .

[0058] Oxygen is first introduced into the compound chamber 1 and the heating plate 2...

specific Embodiment 2

[0074] Specific embodiment two: on the basis of specific embodiment one, please refer to Figure 4-5 _ is a device that can improve the surface quality of aluminum oxidation, and the gas outlet levels of the aluminum gas pipe 4, the oxygen pipe 7 and the nitrogen pipe 8 are distributed from high to low in sequence. As a stable gas, nitrogen has a density lower than that of oxygen and gaseous metal aluminum. The continuous introduction of nitrogen can push the alumina gas to float up, so that the alumina gas can contact the surface of the workpiece 6 in time, and effectively increase the evaporation speed of the workpiece.

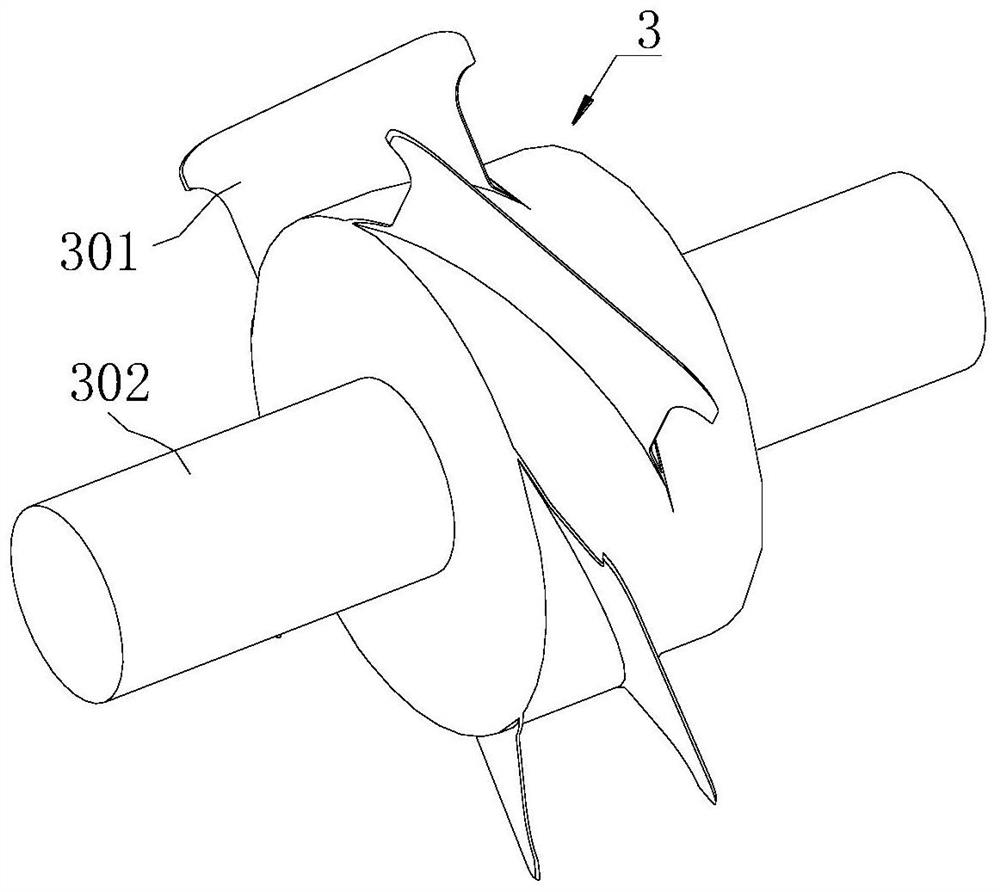

[0075] There are three impellers 3 in the compound chamber 1, and the fan blades 301 of the three impellers 3 correspond to the air outlets of the aluminum air pipe 4, the oxygen pipe 7 and the nitrogen pipe 8 respectively. The axles 302 of the impellers 3 are all rotatably connected with the inner wall of the compound chamber 1 . The impeller 3 can accele...

specific Embodiment 3

[0078] Specific embodiment three: on the basis of specific embodiment two, please refer to Figure 6 A device that can improve the surface quality of aluminum oxidation, and the inner rings of the lower sub-ring 108 and the upper sub-ring 109 are fixed with airbags 103 . The airbag 103 can offset the change in the amount of alumina sprayed due to temperature change. The amount of aluminum oxide ejected at different times is further kept constant to effectively ensure the surface quality of the workpiece 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com