C30 underwater self-compacting concrete and preparation method thereof

A technology for self-compacting concrete and cement, applied in the field of building materials, can solve the problems of increasing the initial setting time of concrete, short gel time, and poor hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

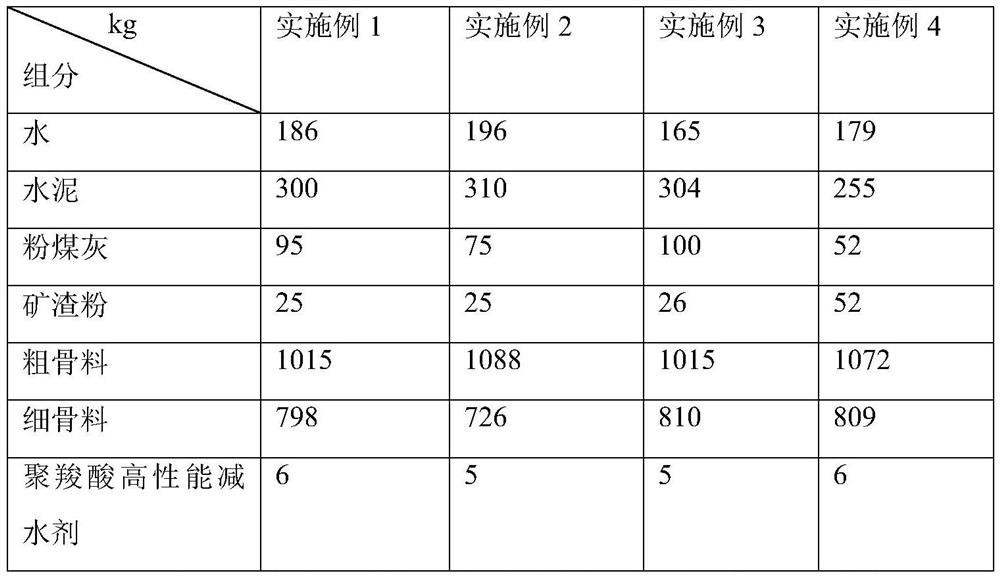

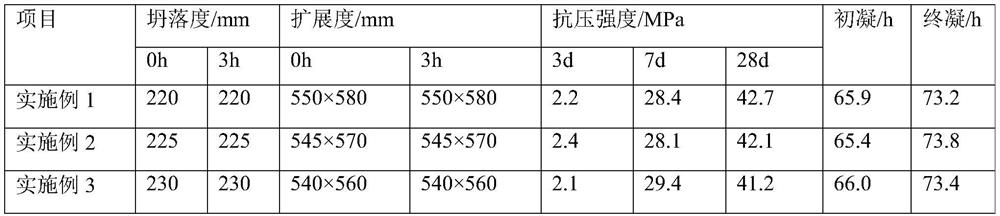

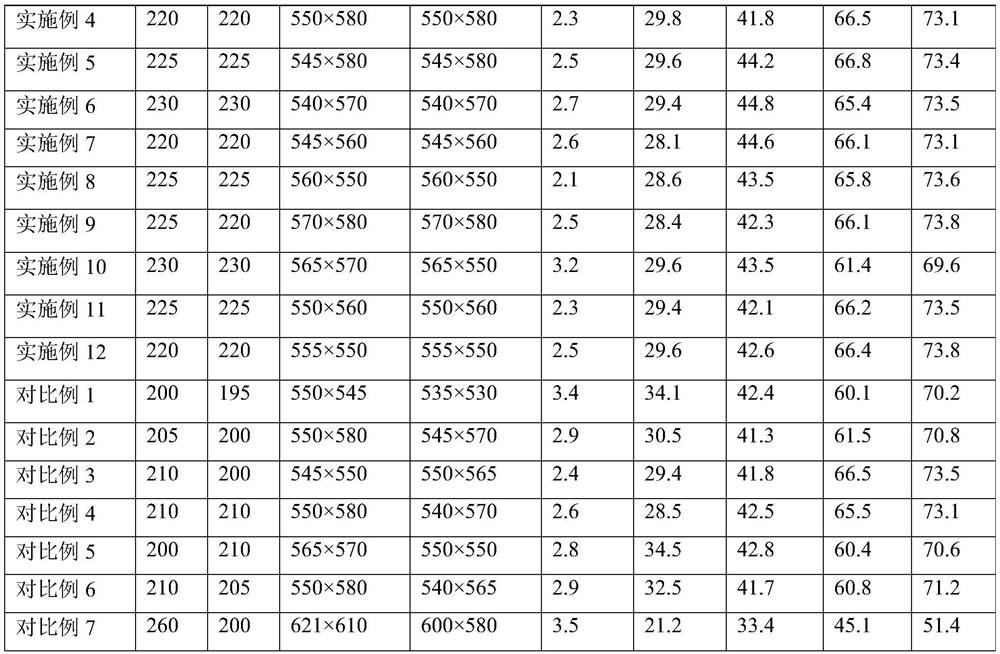

Method used

Image

Examples

preparation example 1-8

[0039] In the preparation example 1-8, copper sulfate is selected from Shandong Huijing Biotechnology Co., Ltd., and the product number is 98; Diss Chemical (Hubei) Co., Ltd., the article number is AA; the extract of Polygonum cuspidatum is from Xi’an Zebang Biotechnology Co., Ltd., the brand is XAZB; the hollow mesoporous silica microspheres are from Jiangsu Xianfeng Nano Material Technology Co., Ltd., model It is 7440-21-3; chitosan is selected from Shandong Fengtai Biotechnology Co., Ltd., and the article number is FT25.

preparation example 1

[0040] Preparation example 1: (1) Grind 1 kg of copper sulfate, 0.6 kg of cassia seed powder, 0.5 kg of tetrakis hydroxymethyl phosphorus sulfate, and 1.1 kg of Polygonum cuspidatum extract to the nanometer level, then add 3 kg of water, mix well, and make a mixed solution;

[0041] (2) Mix 1 kg of hollow mesoporous silica microspheres with 0.5 kg of mixed solution, disperse by ultrasonic, evacuate to -0.01 MPa, centrifuge at 4000 r / min for 5 min, and freeze at -5 °C for 3 h to make an intermediate ;

[0042] (3) Dissolving 2kg of chitosan in 3kg of 5% acetic acid solution, adding 0.1kg of glutaraldehyde and 0.1kg of glycerin, evenly spraying on 3kg of the intermediate, and air-drying to obtain a moss remover.

preparation example 2

[0043] Preparation example 2: (1) Grind 1.5kg of copper sulfate, 1kg of cassia seed powder, 0.7kg of tetrakis hydroxymethylphosphine sulfate, and 1.5kg of Polygonum cuspidatum extract to the nanometer level, then add 4kg of water, mix well, and make a mixed solution;

[0044] (2) Mix 1.5kg hollow mesoporous silica microspheres with 0.8kg mixed solution, ultrasonically disperse, vacuumize to -0.03MPa, centrifuge at 4000r / min for 5min, and freeze at -8°C for 2.5h to prepare Intermediate;

[0045] (3) Dissolving 3kg chitosan in 4kg concentration of 8% acetic acid solution, adding 0.2kg glutaraldehyde and 0.2kg glycerin, evenly spraying on 4kg intermediate, air-dried naturally, made moss remover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com