Processing method of high-altitude Huangjinya tea

A processing method and technology of golden buds, which are applied in the field of processing high-altitude golden bud tea, can solve the problems of golden bud tea that are bland, tasteless, ineffective, and insufficient in aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

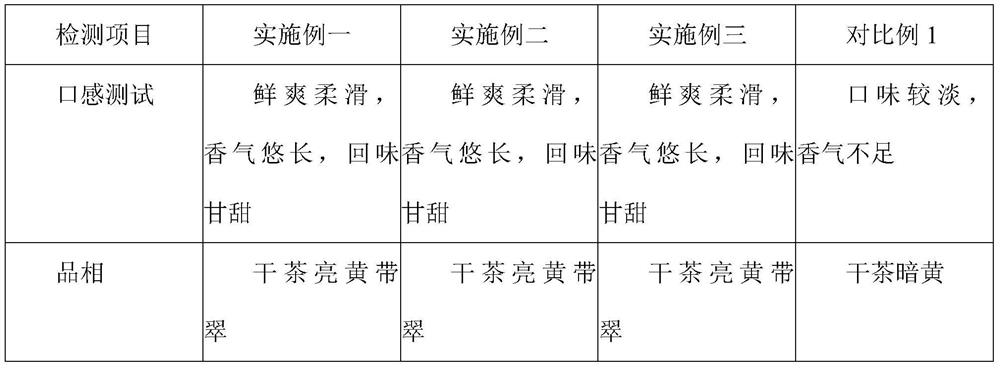

Examples

Embodiment 1

[0023] In the embodiment of the present invention, a processing method of high-altitude golden bud tea leaves comprises the following steps:

[0024] S1. Picking fresh leaves:

[0025] Picking standard 1 bud 1 leaf, 1 bud 2 leaves, the leaf color is jade yellow, the buds and leaves are complete, the length of buds and leaves is the same, the leaf color is jade yellow, the leaves are longer than the buds, when picking fresh leaves, it should be picked in the morning when the dew is dry or in the afternoon Pick before 5 o'clock, use bamboo baskets to hold leaves, loosely pack and transport quickly to prevent steaming and heat deterioration;

[0026] S2: Quick cooling:

[0027] After the fresh leaves are collected, put them in the roasting and aroma enhancing machine to cool them quickly, and spread them evenly in the baking sieve. The amount of leaves per sieve is 2 catties, and the thickness is 3 cm. , the temperature of the roasting and aroma enhancing machine is set at 25°C,...

Embodiment 2

[0039] In the embodiment of the present invention, a processing method of high-altitude golden bud tea leaves comprises the following steps:

[0040] S1. Picking fresh leaves:

[0041] Picking standard 1 bud 1 leaf, 1 bud 2 leaves, the leaf color is jade yellow, the buds and leaves are complete, the length of buds and leaves is the same, the leaf color is jade yellow, the leaves are longer than the buds, when picking fresh leaves, it should be picked in the morning when the dew is dry or in the afternoon Pick before 5 o'clock, use bamboo baskets to hold leaves, loosely pack and transport quickly to prevent steaming and heat deterioration;

[0042] S2: Quick cooling:

[0043] After the fresh leaves are collected, put them in the roasting and aroma enhancing machine to cool them quickly, and spread them evenly in the baking sieve. The amount of leaves per sieve is 2 catties, and the thickness is 3 cm. , the temperature of the roasting and aroma enhancing machine is set to 30°C,...

Embodiment 3

[0055] In the embodiment of the present invention, a processing method of high-altitude golden bud tea leaves comprises the following steps:

[0056] S1. Picking fresh leaves:

[0057]Picking standard 1 bud 1 leaf, 1 bud 2 leaves, the leaf color is jade yellow, the buds and leaves are complete, the length of buds and leaves is the same, the leaf color is jade yellow, the leaves are longer than the buds, when picking fresh leaves, it should be picked in the morning when the dew is dry or in the afternoon Pick before 5 o'clock, use bamboo baskets to hold leaves, loosely pack and transport quickly to prevent steaming and heat deterioration;

[0058] S2: Quick cooling:

[0059] After the fresh leaves are collected, put them in the roasting and aroma enhancing machine to cool them quickly, and spread them evenly in the baking sieve. The amount of leaves per sieve is 2 catties, and the thickness is 3 cm. , the temperature of the roasting and aroma enhancing machine is set to 35°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com