Connecting structure capable of reducing heating of wiring terminal

A terminal and connection structure technology, applied in the direction of contact parts, etc., can solve the problems of small contact area of screw head, poor contact, heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

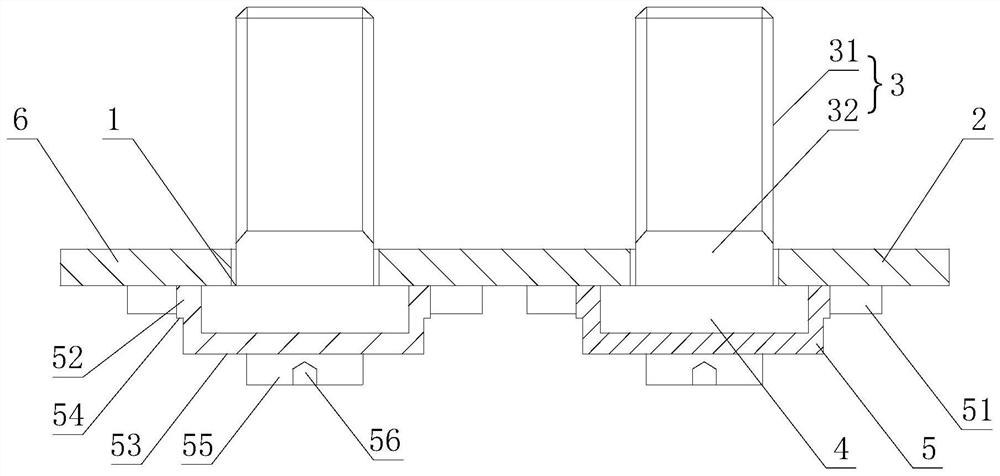

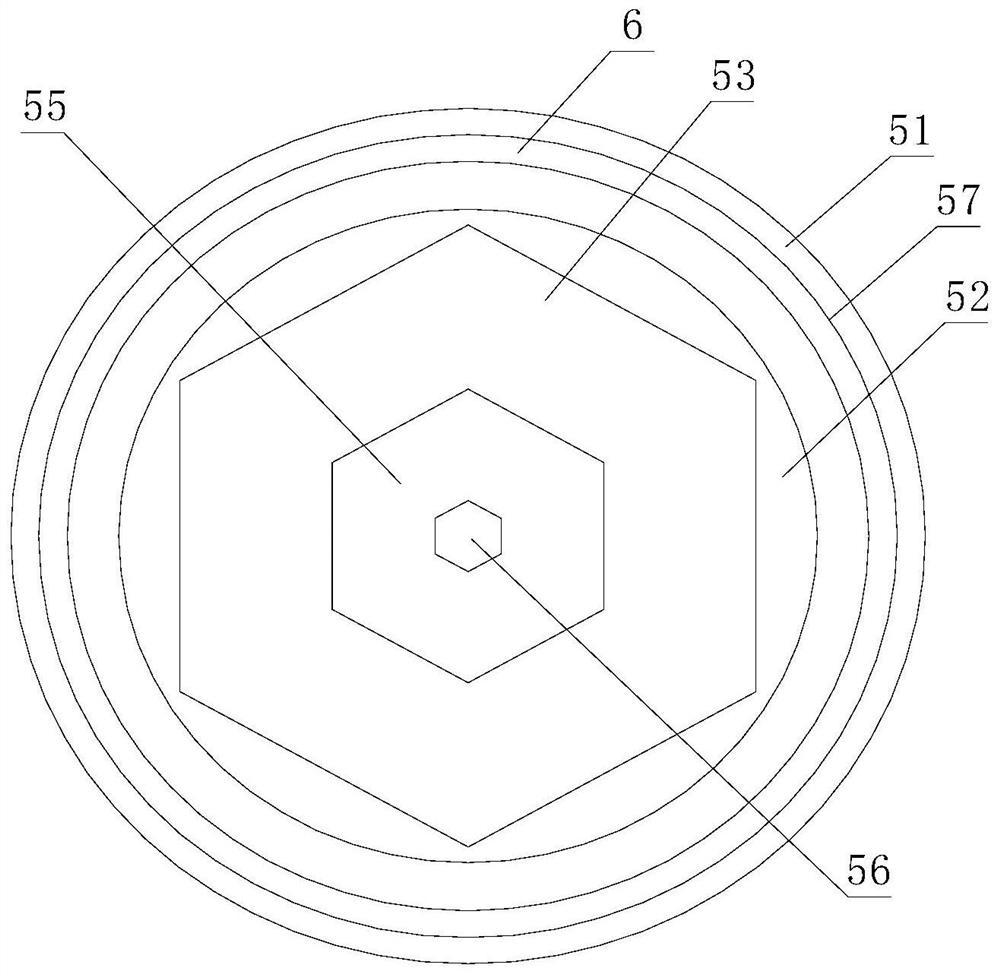

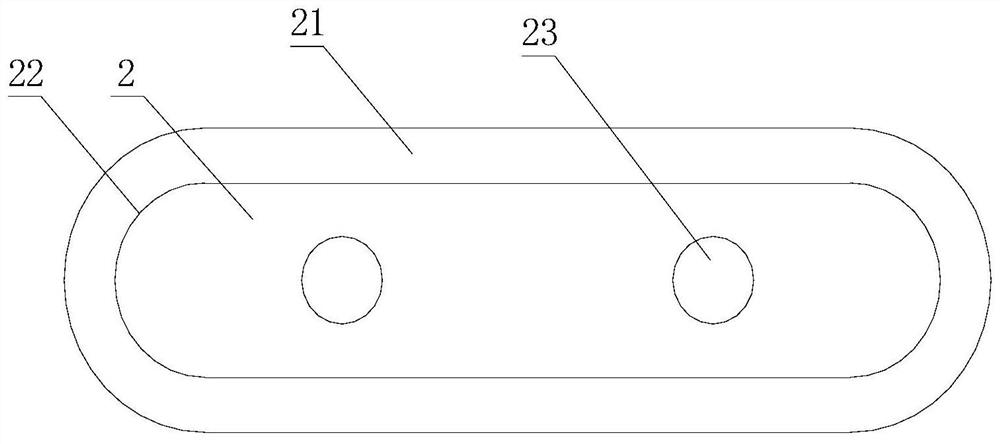

[0022] Such as figure 1 , figure 2 , image 3 As shown, a connection structure capable of reducing heat generation of terminals includes a bolt body 1 and a washer 2 disposed on the bolt body 1, the bolt body 1 includes a screw part 3 and a head 4, and the screw part 3 includes A connecting section 31 for connecting the terminal block and the high-voltage drop-out fuse, and a section 32 for fixing the washer 2, the head 4 is provided with a nut 5, and the nut 5 is detachably installed On the head 4, the nut 5 in this embodiment is detachably installed on the head 4 through threads. Specifically, the outer wall of the head 4 is provided with an external thread that is compatible with the nut 5. The nut 5 is provided with an extension 51 that increases the contact area between the head 4 and the terminal, and the washer 2 is provided with a contact 21 against the extension 51 , between the extension 51 and the contact 21 An indicating assembly 6 is provided to indicate the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com