A device and method for repairing broken water pipes using magnetic fluid

A magnetic fluid and magnetic fluid sealing technology, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of long project period, high cost, and huge project volume, and achieve low repair costs and long life , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

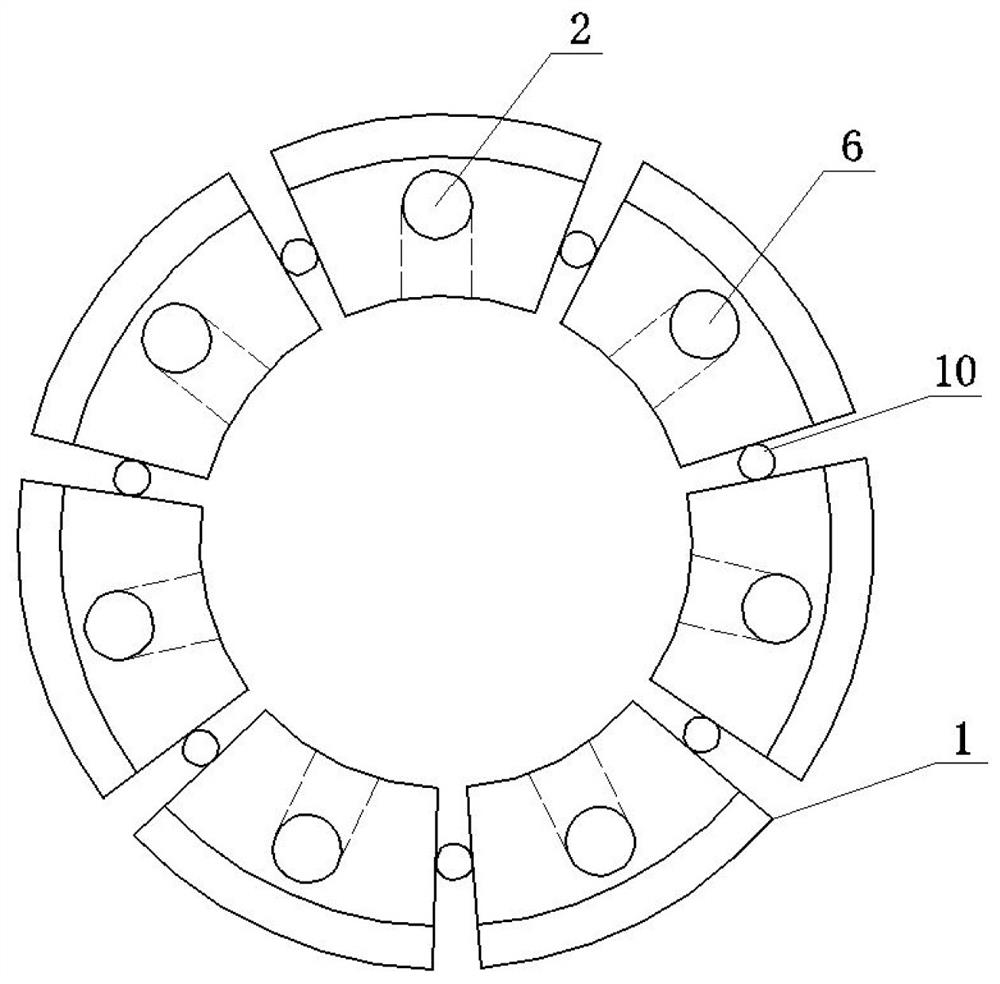

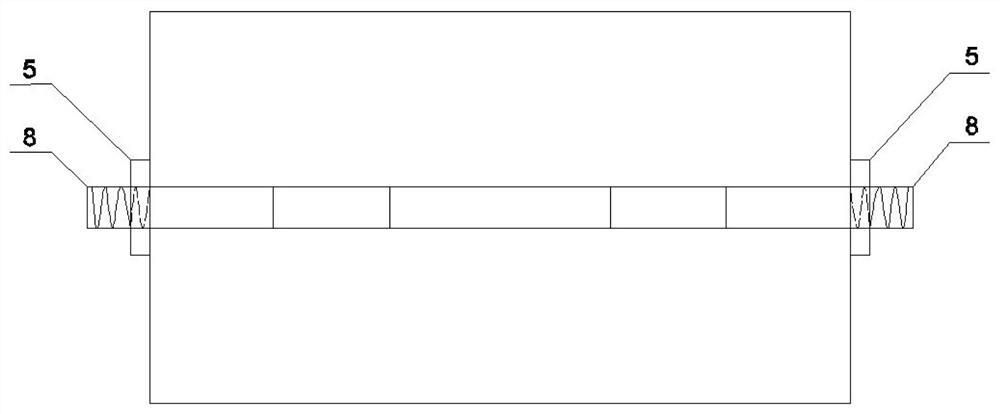

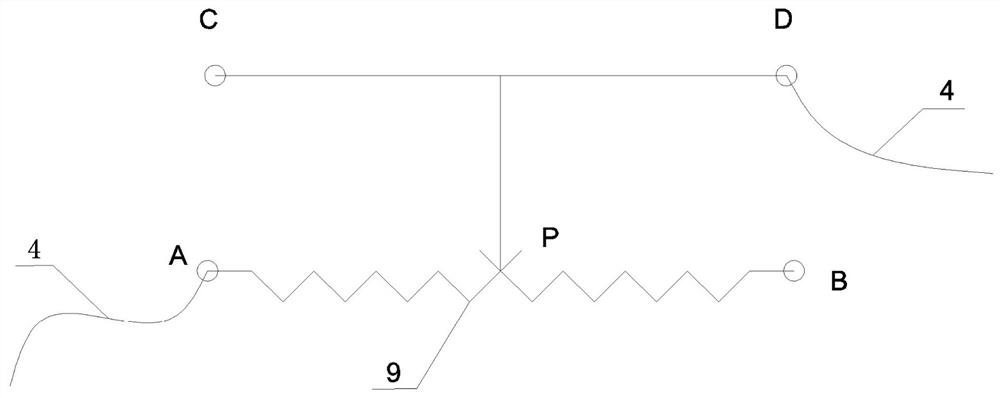

[0044] see Figure 1-4 , a device for repairing broken water pipes using magnetic fluid, which includes an electromagnet prefabrication device 1, the interior of the electromagnet prefabrication device 1 is filled with magnetic fluid 2 and hardener 6; the iron core of the electromagnet prefabrication device 1 is outside A wire 4 is wound, and the wire 4 is connected to the portable power supply 3 through a sliding rheostat 9 . By adopting the above-mentioned device, the caliber of the device can be changed according to the size of the ruptured water pipe to be repaired, and the purpose of repairing the water pipe can be achieved by utilizing the principle of magnetic fluid sealing.

[0045]Further, the electromagnet prefabrication device 1 is assembled from several identical parts. The parts are divided into upper and lower parts, which are connected by welding through the middle part. The upper part is an iron core, and the lower part is composed of poles. Each part is a 1 / 8...

Embodiment 2

[0054] A method for repairing a water pipe using a device for repairing a ruptured water pipe with magnetic fluid comprises the following steps:

[0055] When the pressure against a ruptured water pipe is small:

[0056] Step1.1: Prepared materials: Prepare the parts of the electromagnet prefabrication device 1, the magnetic fluid 2, the sliding rheostat 9, the hardener 6, the wire 4 and the portable power supply 3;

[0057] Step1.2: Assemble the device: connect the two parts with pins according to the size of the broken water pipe in the place where the water pipe is not leaking, and so on, assemble the complete electromagnet prefabricated device 1, and connect the portable power supply 3 The wire 4 of the negative pole is wound on the outside of the device;

[0058] Step1.3: Magnetic fluid seal: move the device to the place where the water pipe is broken, then turn on the power switch, adjust the P of the sliding rheostat 9 to the place with the smallest resistance value, t...

Embodiment 3

[0063] When the pressure against a ruptured water pipe is high:

[0064] Step2.1: Prepared materials: Prepare the parts of the electromagnet prefabrication device 1, the magnetic fluid 2, the sliding rheostat 9, the hardener 6, the wire 4 and the portable power supply 3;

[0065] Step2.2: Assemble the device: connect the two parts with pins according to the size of the broken water pipe in the place where the water pipe is not leaking, and so on, assemble the complete electromagnet prefabricated device, and connect the positive and negative poles of the portable power supply wires wrapped around the outside of the device;

[0066] Step2.3: Form the magnetic fluid sealing ring: turn on the power, adjust the resistance of the sliding rheostat to the maximum, and then inject the magnetic fluid from the injection hole until the magnetic fluid sealing ring is formed;

[0067] Step2.4: Repair the water pipe: move the electromagnet prefabricated device that has formed the magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com