Composite driven snowflake type pile system and construction method

A construction method, snowflake technology, applied in the field of steel sheet piles, can solve problems such as pile foundation instability, inability to provide sufficient side friction resistance, and pile length changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

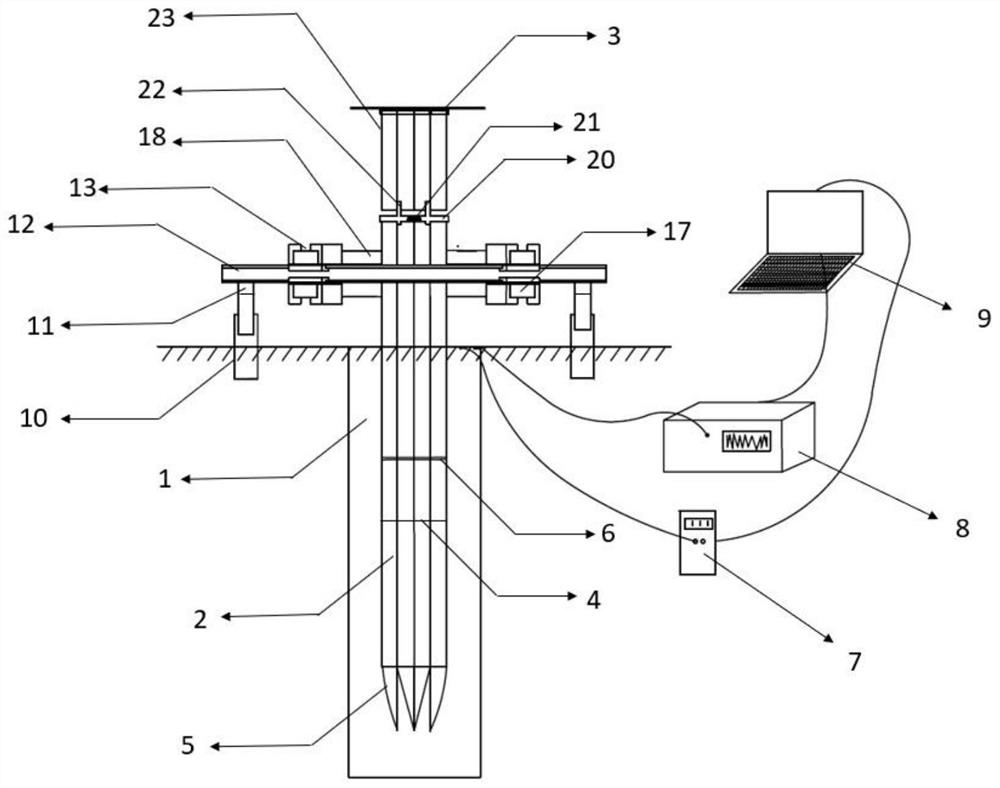

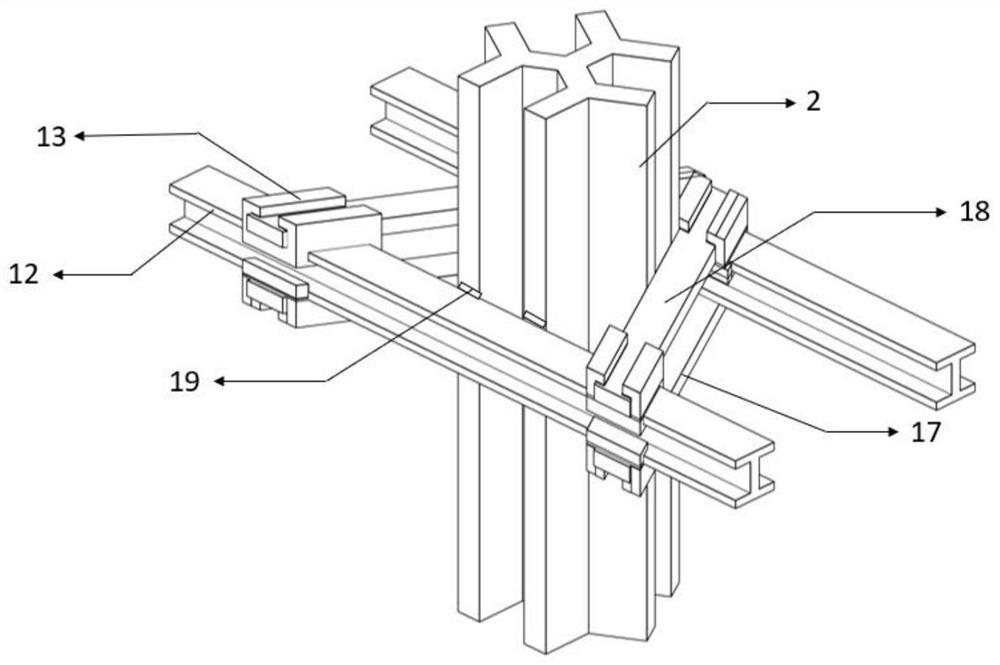

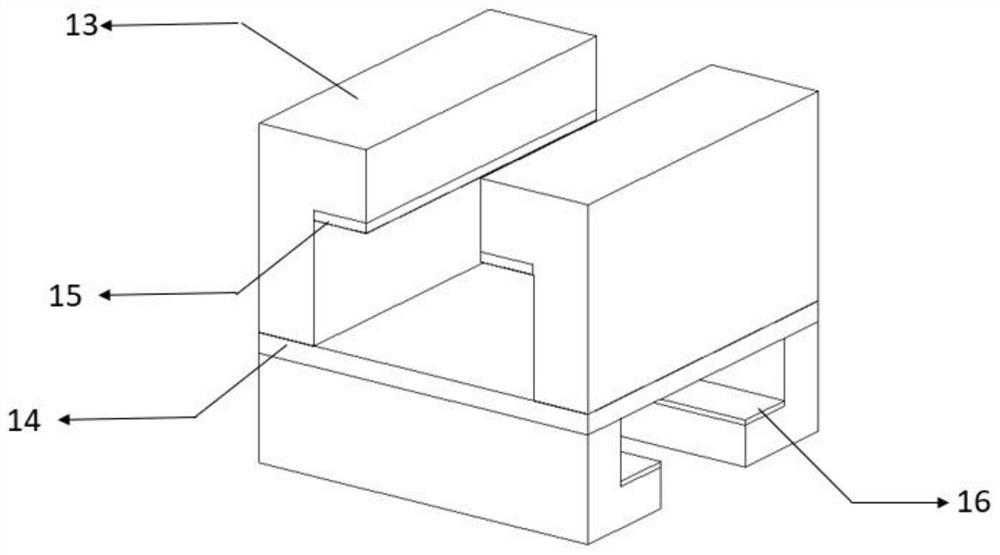

[0050] Such as figure 1 As shown, the composite driven snowflake pile system of the present invention includes an outer core 1 of a cement mixing pile, an inner core 2 of a snowflake-shaped steel sheet pile, a guide assembly, a pile connection device and a cement slurry state monitoring system.

[0051] The pile body of the snowflake-shaped pile is composed of the outer core 1 of the cement mixing pile and the inner core 2 of the snowflake-shaped steel sheet pile, that is, the inner core of the snowflake-shaped steel sheet pile is contained in the composite driven-in snowflake-shaped pile body as a support. The inner core of the snowflake-shaped steel sheet pile includes a pile body, a stiffener on the pile body, a pile cap 3 on the top of the inner core, an inner core support 4 and a pile tip 5 on the bottom of the steel sheet pile.

[0052] The cross section of the pile body of the inner core 2 of the steel sheet pile is snowflake-shaped, Y-shaped with an included angle of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com