Preparation method of viscosity-reducing mud-resistant polycarboxylic acid water reducing agent

A technology of polycarboxylic acid and anti-mud type, which is applied in the field of concrete water reducer, which can solve the problems of limited anti-mud and viscosity reduction effects, and achieve the effects of improving construction performance, prolonging slump retention time, and reducing plastic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

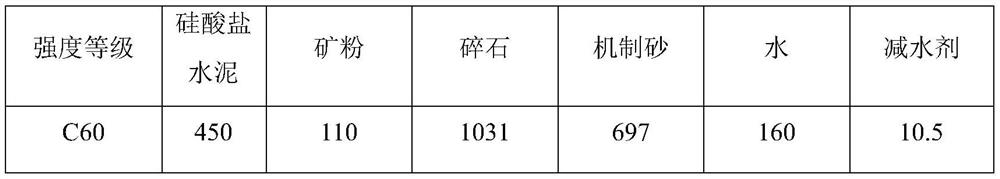

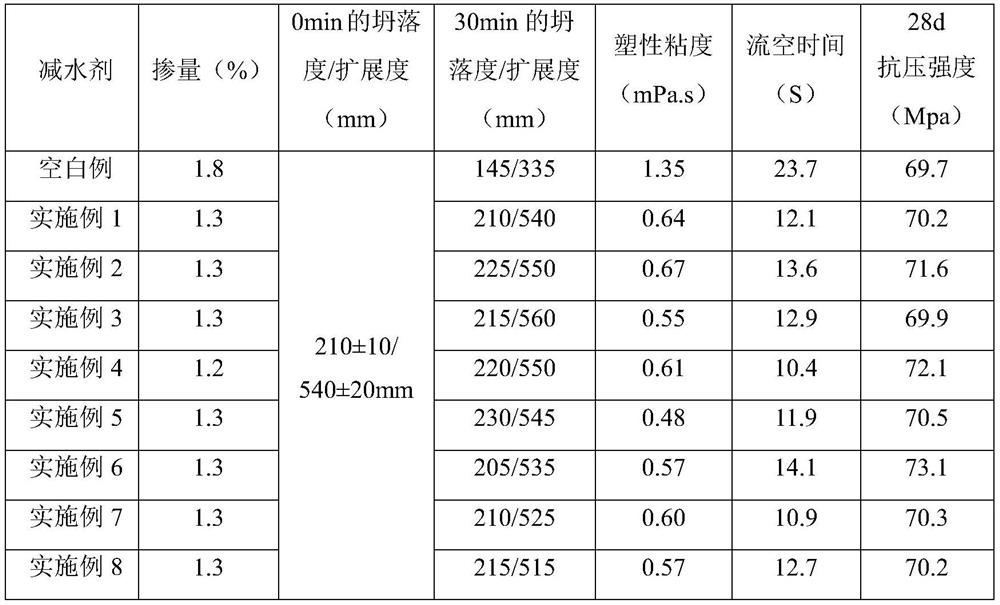

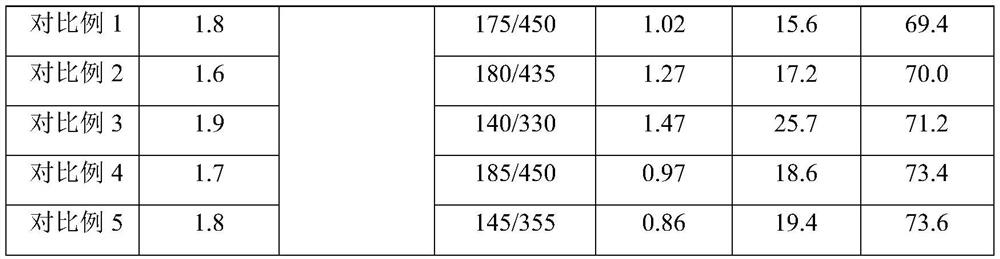

Examples

Embodiment 1

[0023] The preparation method of the polycarboxylate water reducer provided in this embodiment is:

[0024] S1. Mix 11.4g trifluoroacetic acid and 0.2g p-toluenesulfonic acid evenly, raise the temperature to 52°C, add 10g prenyl alcohol dropwise to the above mixture within 1h in a constant pressure dropping funnel, and keep stirring , reacted at 52°C under reflux for 2 hours, added calcium chloride to dry for 12 hours after the reaction, then added anhydrous magnesium sulfate to dry for 12 hours, and collected the product by distillation to obtain the viscosity-reducing functional monomer Ⅰ.

[0025] S2. Take 120g allyl polyoxyethylene ether, 0.77g benzallyl malonitrile, and 80g water and mix evenly to ensure that allyl polyoxyethylene ether and benzallyl malonitrile are fully dissolved in the water phase, and take 0.12g vitamin C. 0.6g of mercaptopropionic acid and 40g of water were fully dissolved and stirred uniformly as liquid A, and 1.44g of acrylic acid, 1.82g of viscosi...

Embodiment 2

[0028] The preparation method of the polycarboxylate water reducer in this example is basically the same as in Example 1, except that in step S2, the amount of viscosity-reducing functional monomer I is 3.64 g, the amount of acrylic acid is 2.88 g, and the amount of benzyl The amount of malononitrile used is 1.54 g, that is, the molar ratio of allyl polyoxyethylene ether, acrylic acid, viscosity-reducing functional monomer I, and benzallyl dinitrile is 1:0.4:0.2:0.1.

Embodiment 3

[0030] The preparation method of the polycarboxylate superplasticizer in this example is basically the same as that in Example 1, except that in step S2, the amount of the viscosity-reducing functional monomer I is 1.82 g, the amount of acrylic acid is 3.6 g, and the amount of benzyl The amount of malononitrile used is 1.54 g, that is, the molar ratio of allyl polyoxyethylene ether, acrylic acid, viscosity-reducing functional monomer I, and benzallyl dinitrile is 1:0.5:0.1:0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com