Grey spun rayon cloth textile machine and use method thereof

A technology for cotton grey cloth and textile machine, which is applied in the field of rayon grey cloth textile machine, can solve the problems of affecting the cotton yarn spinning efficiency, being easy to be scratched, and the yarn of the guide hole being ground with sharp edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

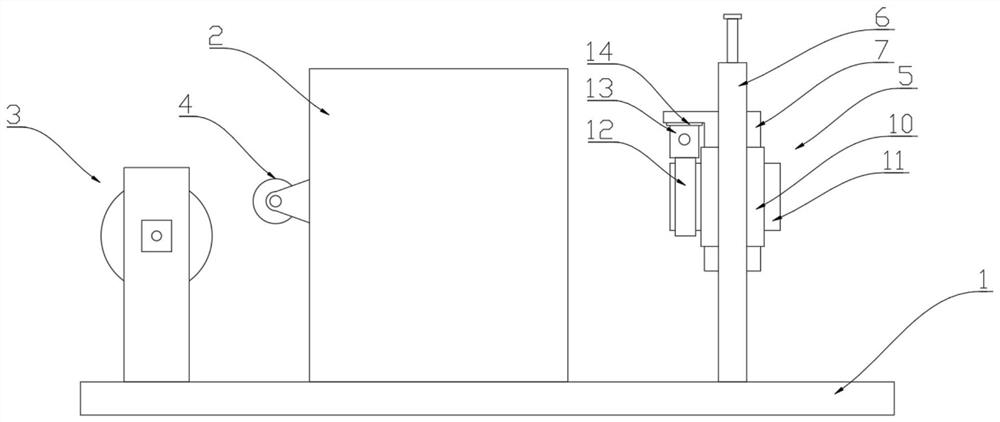

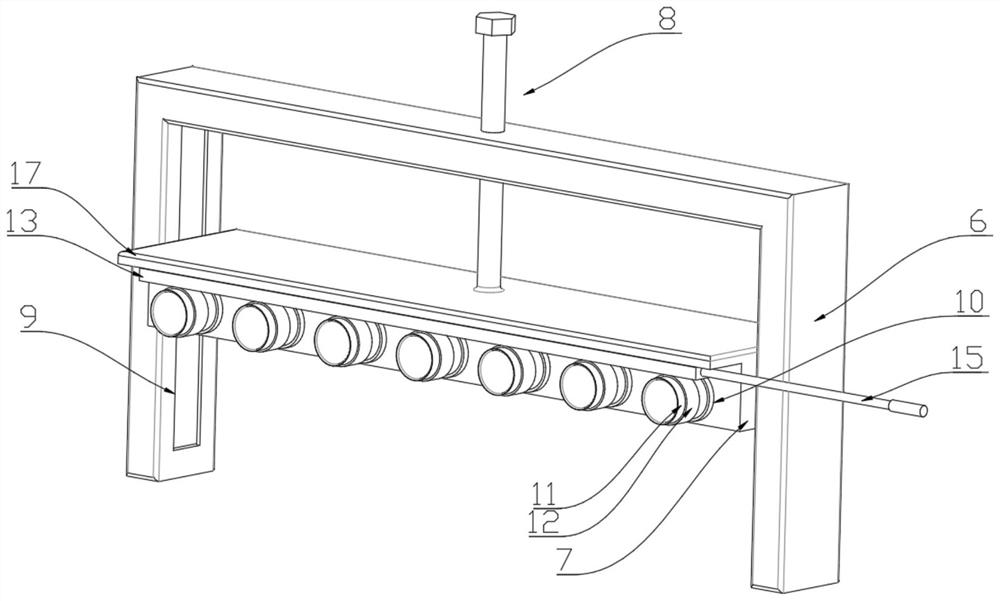

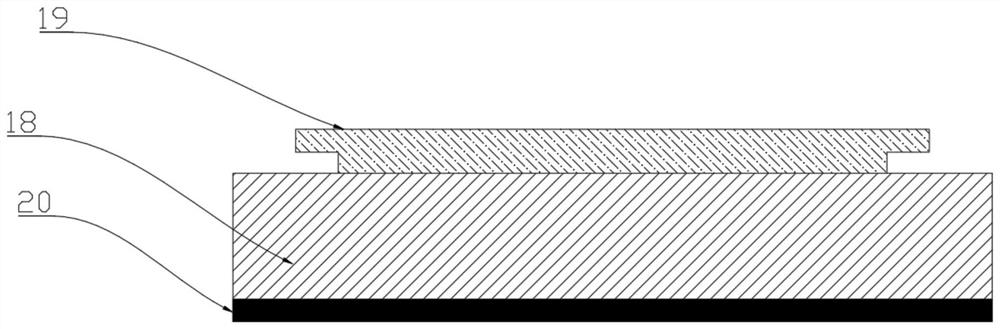

[0026] Please refer to the figure, in the embodiment of the present invention, a rayon gray cloth spinning machine includes a base 1, a knitting unit 2, a winding unit 3, a guide roller 4 and a yarn guiding unit 5; the knitting unit 2, the winding unit 3. The yarn guide unit 5 is fixedly installed on the base 1, the knitting unit 2 is located between the winding unit 3 and the yarn guide unit 5, and the yarn for textile enters into the knitting unit 2 from the yarn guide unit 5, and is 2. Winding is carried out on the winding unit 3 after internal weaving. The material guide roller 4 is arranged on the knitting unit 2 and faces the winding unit 3, and the knitted rayon gray cloth is discharged toward the winding unit 3, which is convenient for winding Unit 3 rewinds.

[0027] The yarn guide unit 5 faces the knitting unit 2, and the yarn passes through the yarn guide unit 5, and the yarn is sent into the knitting unit 2 for weaving through the separate delivery of the yarn guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com