Intelligent paper feeding and smoothing mechanism of printing machine for intelligent manufacturing

A technology of intelligent manufacturing and printing machines, which is applied in the direction of object supply, pile separation, and thin material processing, etc., and can solve problems such as equipment outage sheets, wrinkled paper jams, and unwrinkled paper smoothing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

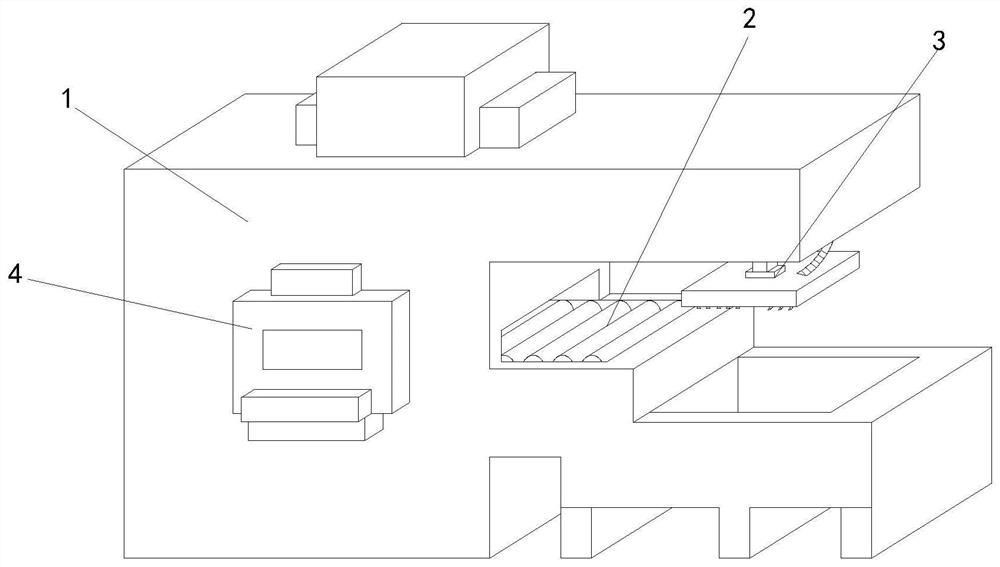

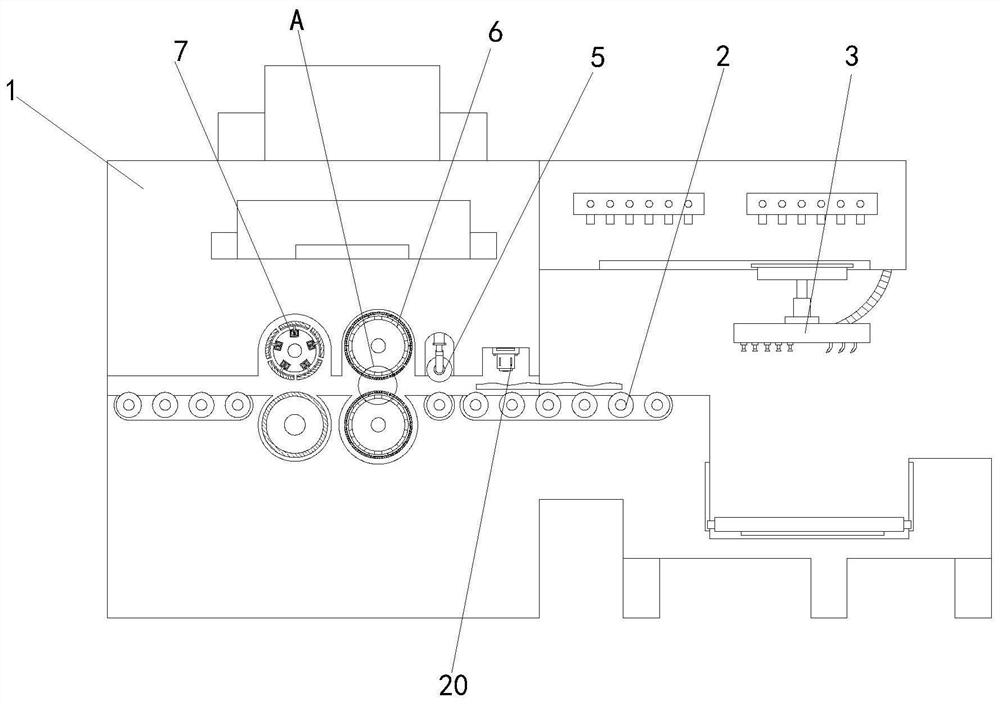

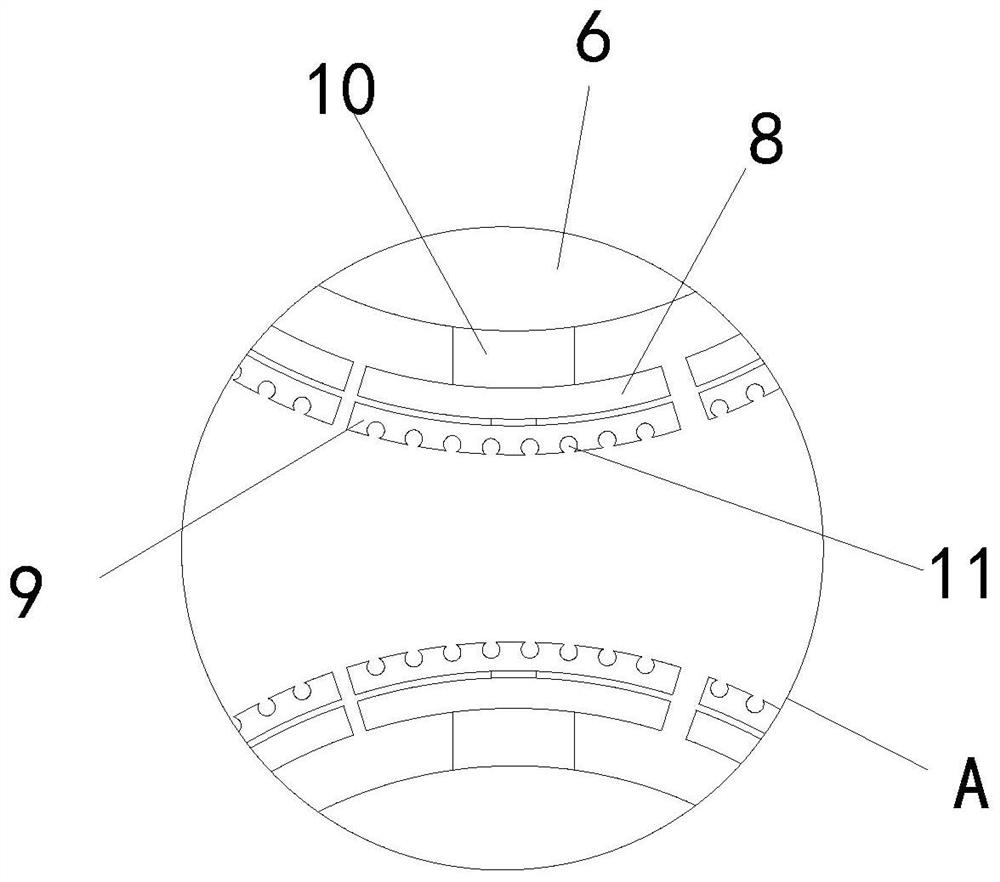

[0028] see Figures 1 to 6 , a schematic plan view and a three-dimensional structure view of an intelligent paper feeding and smoothing mechanism for an intelligently manufactured printing machine.

[0029] An intelligent manufacturing printing machine intelligent paper feeding and smoothing mechanism, including a device main body 1, a paper feeding wheel 2 is installed inside the right side of the device main body 1, a paper suction device 3 is installed on the upper right side of the device main body 1, and the front of the device main body 1 A pressurizer 4 is installed, and a platen runner 5 is installed on the left side corresponding to the paper feed runner 2 inside the device main body 1, and a smoothing device 6 is installed on the left side of the presser roller 5, and the left side of the smoothing device 6 A heating device 7 is installed, a water tank 12 is arranged inside the smoothing device 6, an infrared range finder 20 is installed inside the device main body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com