Integral leveling structure of fabricated floor

A prefabricated and floor technology, applied in local raised floors, building structures, floors, etc., can solve the problems of low floor leveling efficiency, affecting construction progress, and small floor leveling area, achieving wide applicability, Simple operation, increase the effect of flattened area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

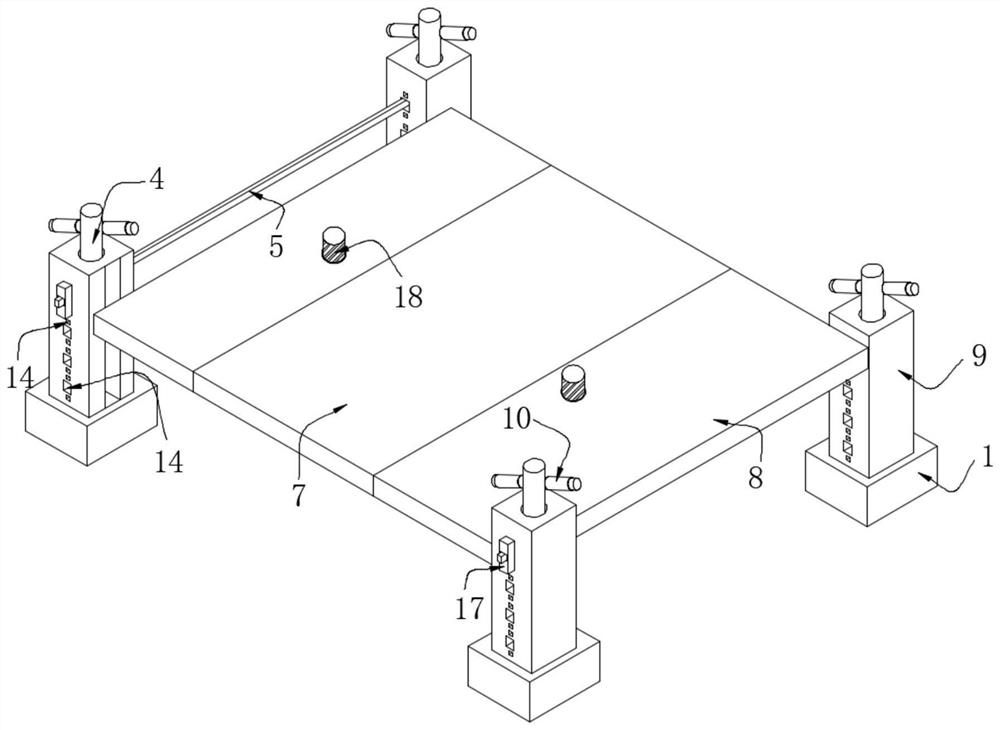

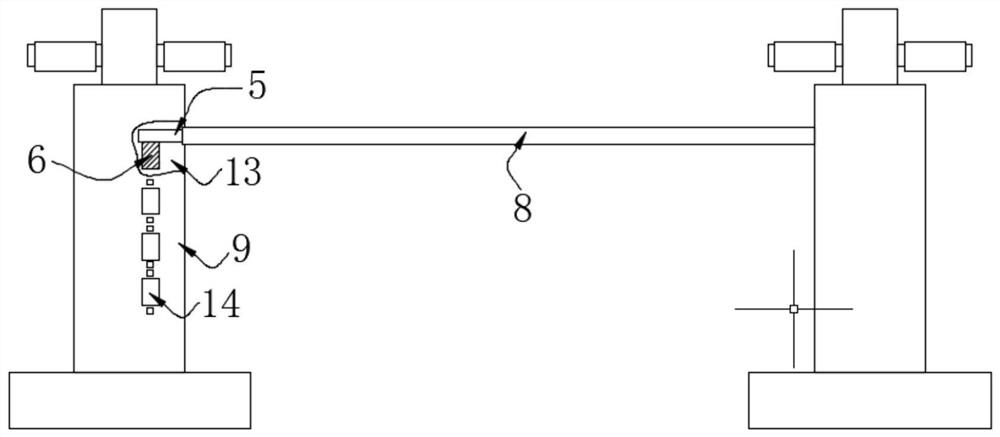

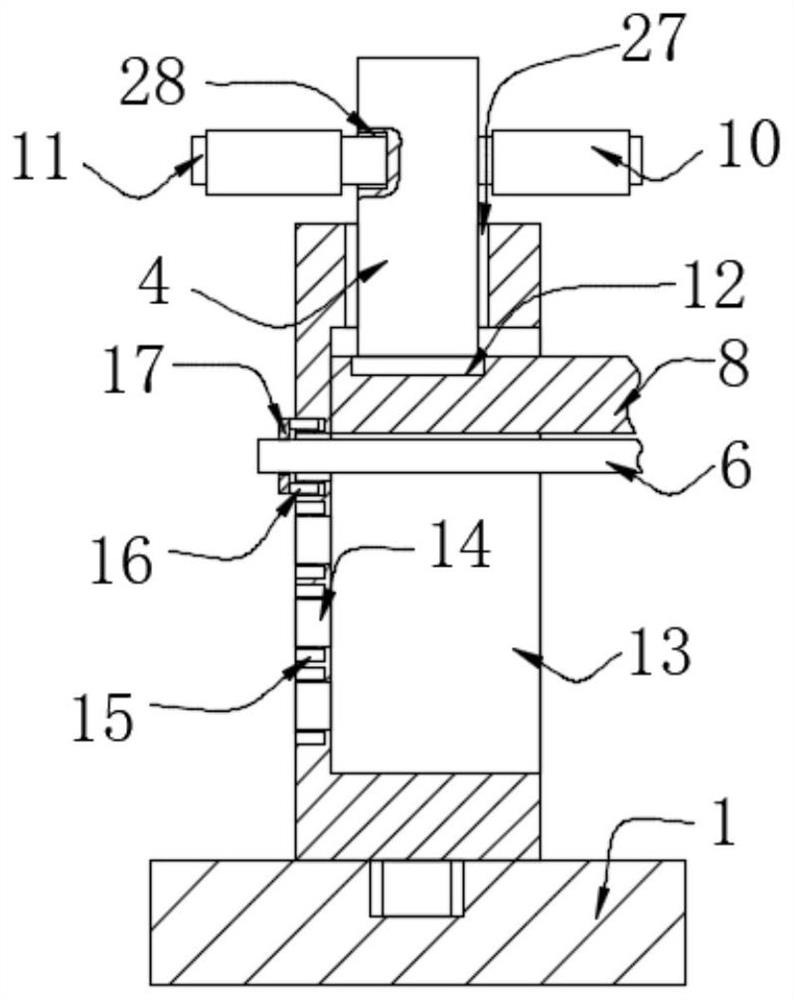

[0026] see Figure 1-7 , the present invention provides a technical solution: an overall leveling structure of a prefabricated floor, including four fixed blocks 9, and the insides of the four fixed blocks 9 are respectively provided with first slide grooves 13 and equidistantly arranged spacers. Groove 14, the top of fixed block 9 is provided with the 4th through hole 27, and the inner side wall of the 4th through hole 27 is threadedly connected with bar body 4, and the inner side wall of two position-limiting grooves 14 inserts limit plate 6, limit plate Two connecting plates 17 are inserted symmetrically on both sides of the 6, the limiting plate 6 is located in the middle of the connecting plate 17, the inner side wall of the first chute 13 is respectively slidably connected with the second plate body 8 and the support plate 5, and the rod body 4 The bottom is arranged on the top of the second plate body 8, and the inside of the second plate body 8 is respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com