Dry bulk cargo wharf loading and unloading process system and method suitable for ultra-large water level difference

A technology for water level difference and dry bulk cargo, applied in the field of dry bulk cargo terminal loading and unloading process systems, can solve problems such as occupation of waterways and decreased efficiency of equipment loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

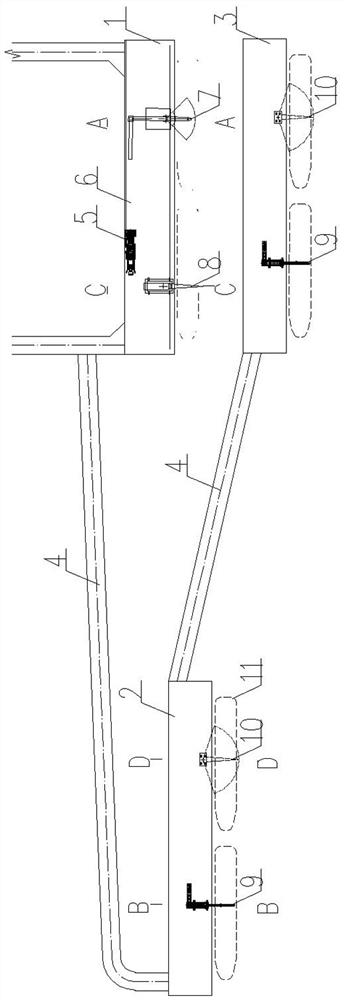

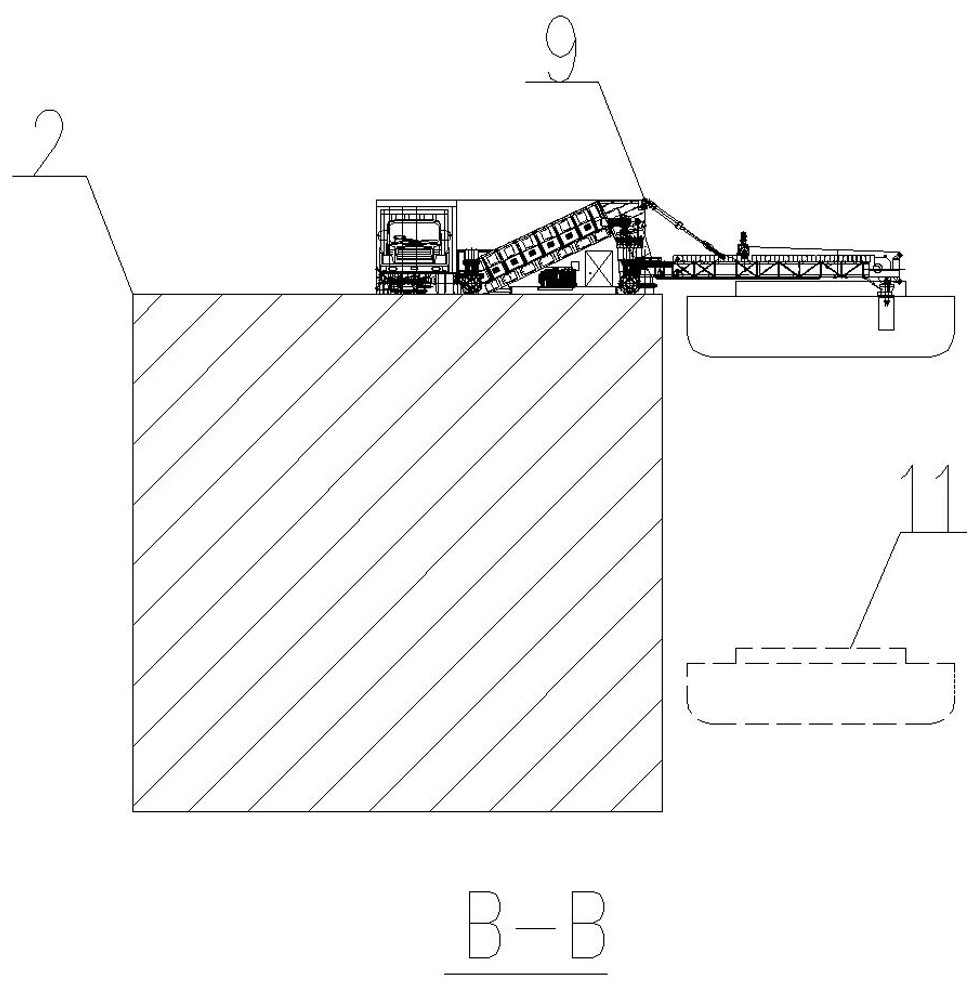

[0027] This embodiment is a dry bulk cargo wharf loading and unloading process system suitable for super large water level difference. Taking the super large water level difference of 60 meters as an example, the dry bulk cargo wharf loading and unloading system includes high water level loading and unloading platforms located at different elevations, medium water level loading and unloading The platform and the low-water level loading and unloading platform are staggered in horizontal position between adjacent loading and unloading platforms, and the houses of each loading and unloading platform are connected in series through the connecting road in turn.

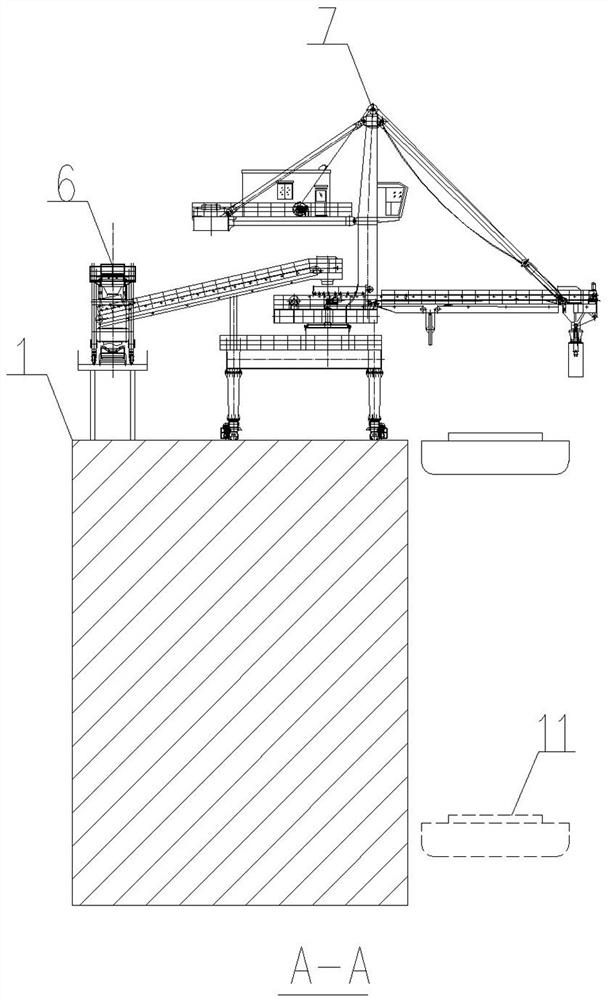

[0028] In this embodiment, the high-water level loading and unloading platform is suitable for a working water level difference of 30 meters. The high-water level loading and unloading platform adopts rail-type equipment for operation, and is equipped with a surface feeder, a belt conveyor and a rail-based ship loader for bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com