Calendering device for PVC plastic floor

A calendering device and technology for plastic flooring, applied in the field of plastic flooring, can solve the problems of inability to trim PVC plastic flooring, inconvenience, and reduce the functionality of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

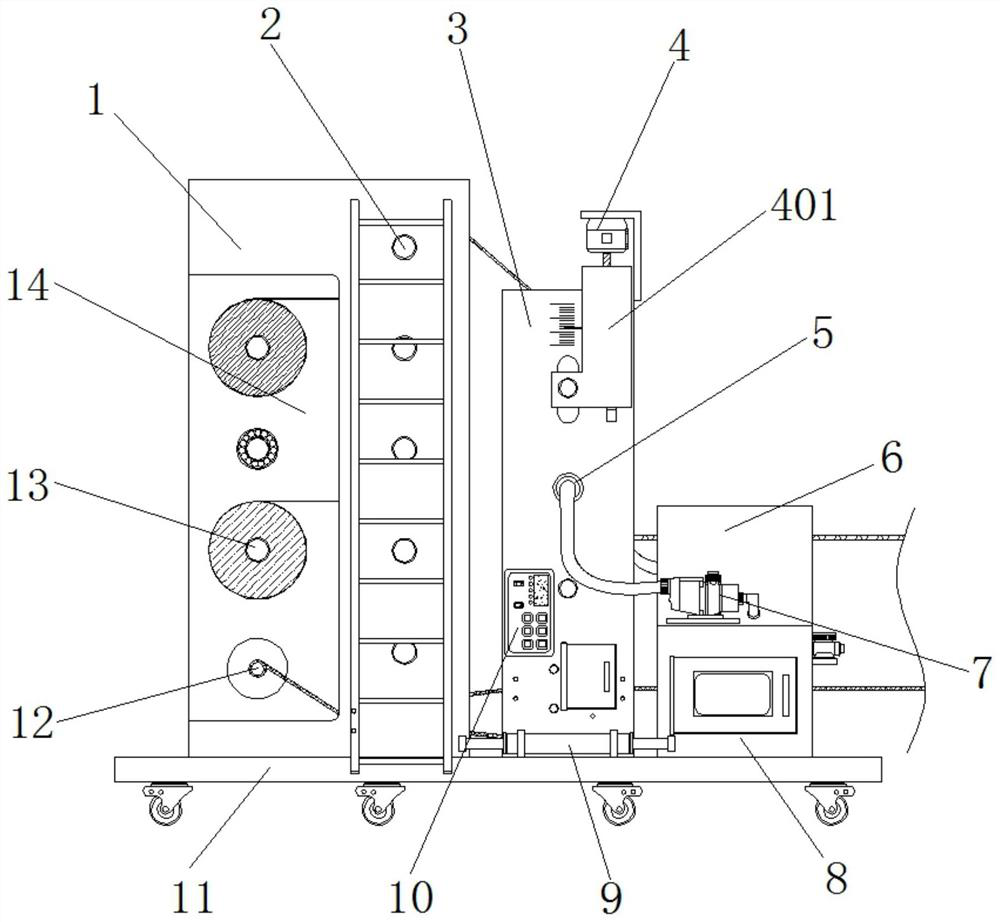

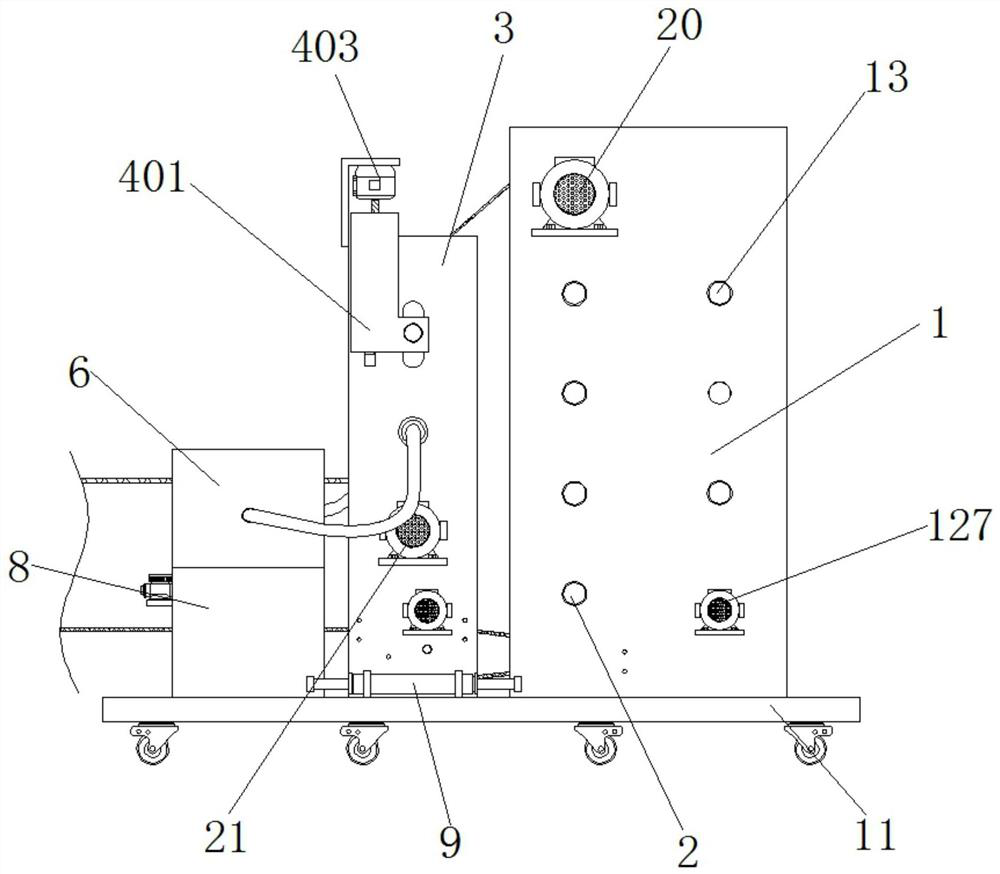

[0039] Example 1, such as figure 1 , 2 As shown in , 3, 5 and 7, when the PVC plastic floor is started to be calendered, first control the electric plus assembly inside the circulating oil tank 16 to heat the oil inside it, and then control the oil delivery pump 7 to heat the oil inside the circulating oil tank 16 The hot oil is transported to the inside of the hollow mirror roller 15, and then flows back from the hollow mirror roller 15 to the inside of the circulating oil tank 16 to form a circulating flow of hot oil, and the hot oil inside the circulating oil tank 16 conducts part of the heat into the preheating chamber 6. Inside, the PVC plastic floor is preheated, and the PVC plastic floor is preliminarily calendered when it passes between the hollow mirror roller 15 and the first mirror roller 18, and the PVC plastic floor passes through the hollow mirror roller 15 and the second mirror roller. Between the mirror rollers 405, it is processed by secondary calendering. Wh...

Embodiment 2

[0040] Example 2, such as Figure 1-7 As shown, if it is necessary to adjust the thickness of the PVC plastic floor after calendering, the first servo motor 403 is controlled by the control panel 10 to drive the threaded rod 402 to rotate. The second mirror roller 405 connected to the inner side of the frame 401 will also rise and fall accordingly, thereby adjusting the distance between the second mirror roller 405 and the hollow mirror roller 15, and controlling the thickness of the PVC plastic floor after calendering. When the finished PVC plastic floor passes between the two groups of material cutting rollers 125, the two sides of the PVC plastic floor after adding the film will be trimmed by the cooperation of the annular blade 124 and the annular groove 128, and the operator will cut the head end of the waste edge material. After passing through the second guide roller 126 and the third guide roller 122 in sequence, it is fixed on the winding material roller 121 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com