High-precision bushing assembly centering device and bushing centering assembly method

A centering device, high-precision technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of cracking, affecting the coaxiality of the bush and the shaft seat hole, excessive extrusion of the bush and the shaft seat hole, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

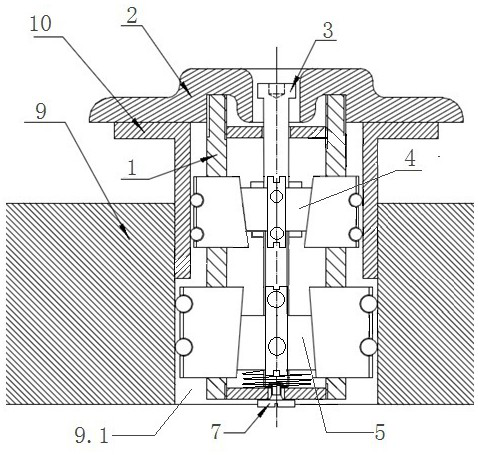

[0038] This embodiment discloses a high-precision bushing 10 assembly centering device, as a basic embodiment of the present invention, including a centering shaft 3, a supporting bushing 1, a bushing supporter 4 and a shaft seat hole supporter 5 ; The support shaft sleeve 1 is a hollow cylinder structure, the shaft center of the top of the support shaft sleeve 1 is provided with a fixed shaft hole 1.2.1, and the shaft center of the bottom of the support shaft sleeve 1 is fixed with a threaded fixed shaft for connecting the centering shaft 3 Nail 7; the top of the support sleeve 1 is detachably provided with a shaft cover 2 for pressing the bushing 10 (the bottom of the shaft cover 2 is provided with a rubber pad 6), and the shaft center of the shaft cover 2 is provided with a shaft hole 2.1; The mandrel 3 is set coaxially with the support sleeve 1, and one end of the centering shaft 3 passes through the shaft hole 2.1, and is inserted into the support sleeve 1 through the fixe...

Embodiment 2

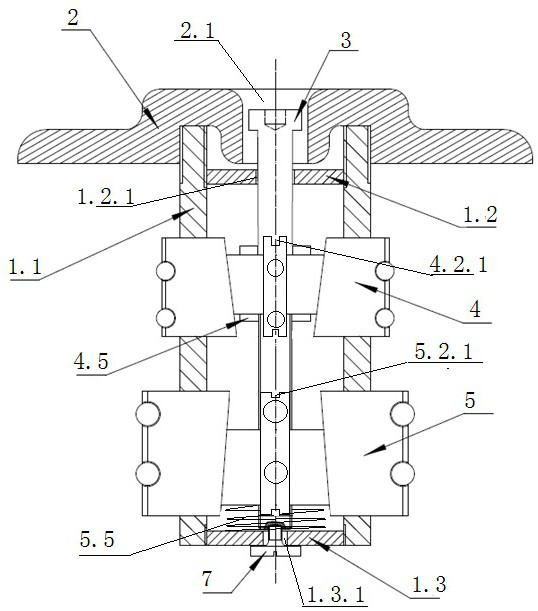

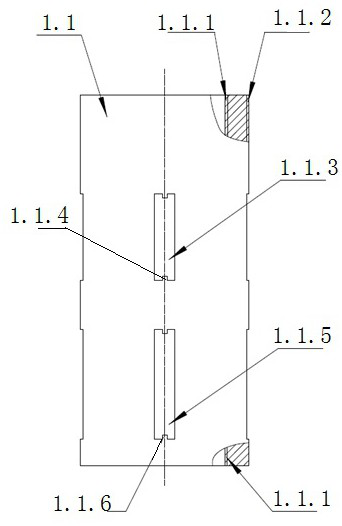

[0042] This example discloses a high-precision bushing 10 assembly centering device, as a preferred embodiment of the present invention, that is, in Example 1, the support shaft sleeve 1 includes a sleeve body 1.1, an upper limit cover 1.2 and a lower limit cover 1.3; the sleeve body 1.1 is a hollow cylinder structure with both ends open, and the two ends of the sleeve body 1.1 are respectively provided with internal thread structures 1.1.1, and the upper limit cover 1.2 is detachably connected to the sleeve through the internal thread structure 1.1.1 On the top of the body 1.1, the lower limit cover 1.3 is detachably arranged on the bottom of the sleeve body 1.1 through the internal thread structure 1.1.1; the end of the support shaft sleeve 1 near the top is provided with an external thread structure II 1.1.2 for connecting the shaft cover 2, A connection basis is provided between the centering shaft 3 and the threaded shaft fixing nail 7 .

[0043] In the actual use of this...

Embodiment 3

[0045] This embodiment discloses a high-precision bushing 10 assembly centering device, as a preferred embodiment of the present invention, that is, in embodiment 1, a nail-piercing hole 1.3.1 is opened at the axis of the bottom of the support sleeve 1 , the nail body of the threaded fixed axis nail 7 is inserted into the inside of the support sleeve 1 through the nail hole 1.3.1, the top cap of the threaded fixed axis nail 7 is fixedly connected with the bottom of the support sleeve 1; the top of the centering shaft 3 is set There is a connection end 3.1 for cooperating with a wrench.

[0046]The nail-piercing hole 1.3.1 of this technical solution is used as a reference for the threaded fixed-axis nail 7 to find the central axis of the support bushing 1, and the connection between the threaded fixed-axis nail 7 and the support bushing 1 under the condition of setting the nail-piercing hole 1.3.1 structure, the supporting force at the bottom of the support sleeve 1 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com