Aluminium profile spraying box capable of working continuously

A technology of aluminum profiles and boxes, applied in spray booths, spray devices, etc., can solve problems such as uneven spraying, delayed spraying speed, and health injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

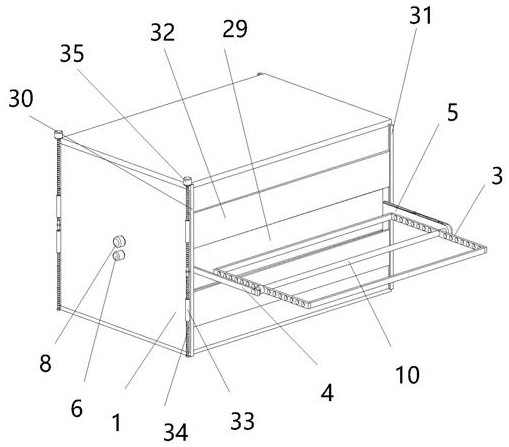

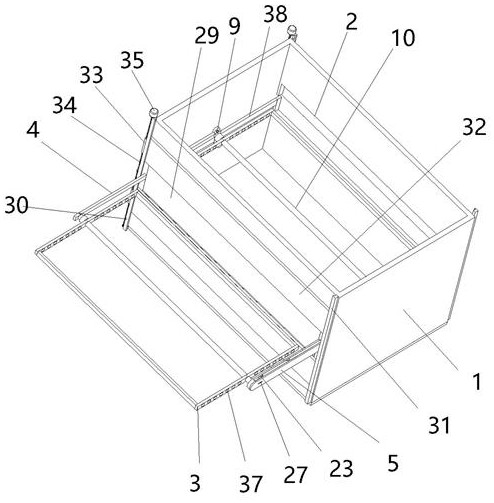

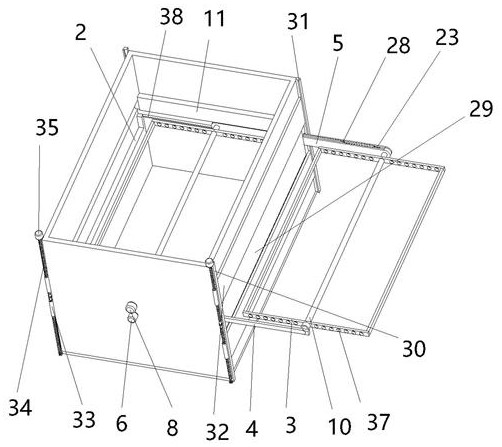

[0026] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

[0027] A continuously working aluminum profile spraying box includes a box body 1 and a conveying frame, the two sides of the box body 1 are respectively provided with inlets and outlets 2, and the conveying frame is horizontally arranged in the middle of the box body 1; the conveying frame can be Sliding between the two inlets and outlets 2, the two sides of the conveying frame are respectively rotated to be provided with a rotating frame 3, and the rotating frame 3 is rotated and arranged on the conveying frame; the conveying frame includes a moving rod 4 and a locking slide bar 5, The moving rod 4 and the locking slide bar 5 are arranged in parallel; a moving motor 6 is provided on the outside of the box body 1, and one end of the moving motor 6 extends into the inside of the box body 1, and a moving wheel 7 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com