Additive atomization smoking equipment and smoking method applied to additive smoking equipment

An additive and smoking technology, which is applied in the direction of tobacco, etc., can solve the problems of uniform mixing of tobacco, inconsistent taste, poor taste of smoking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

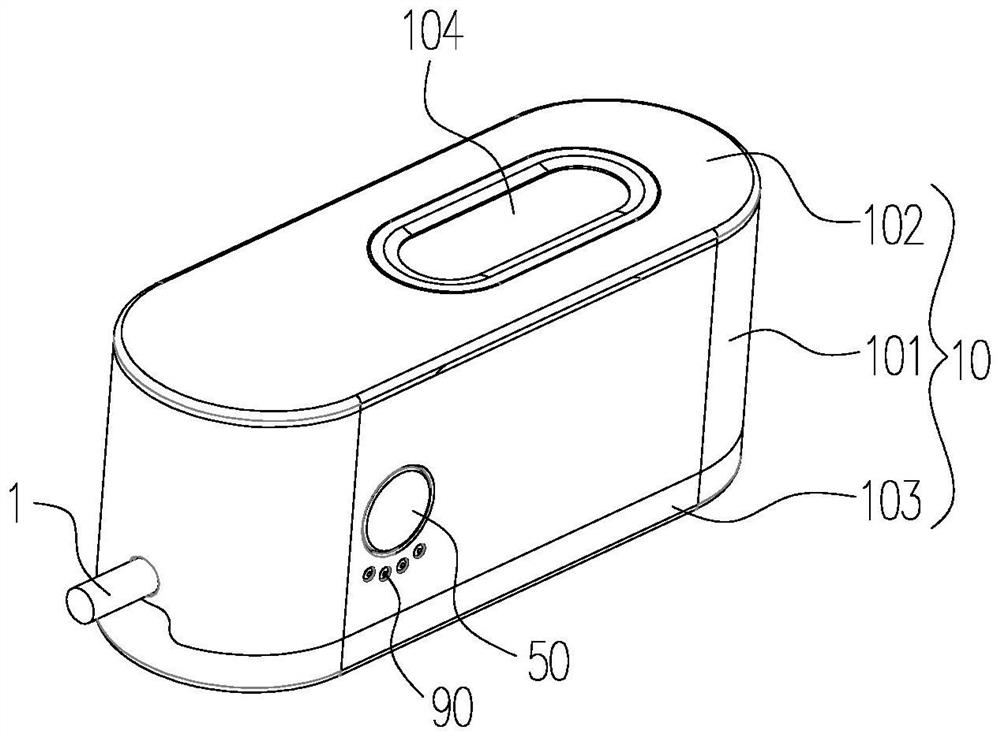

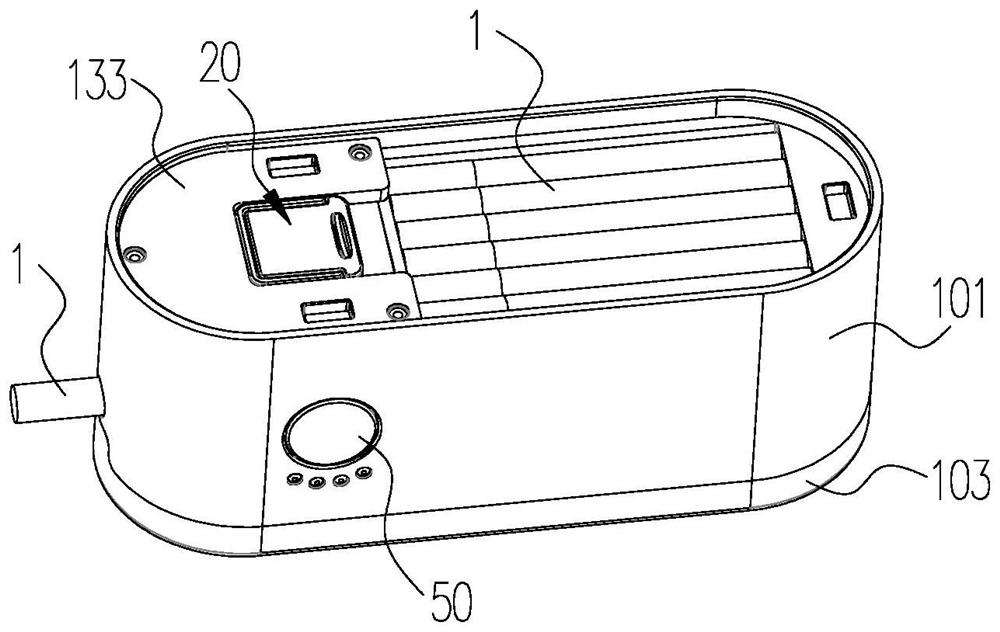

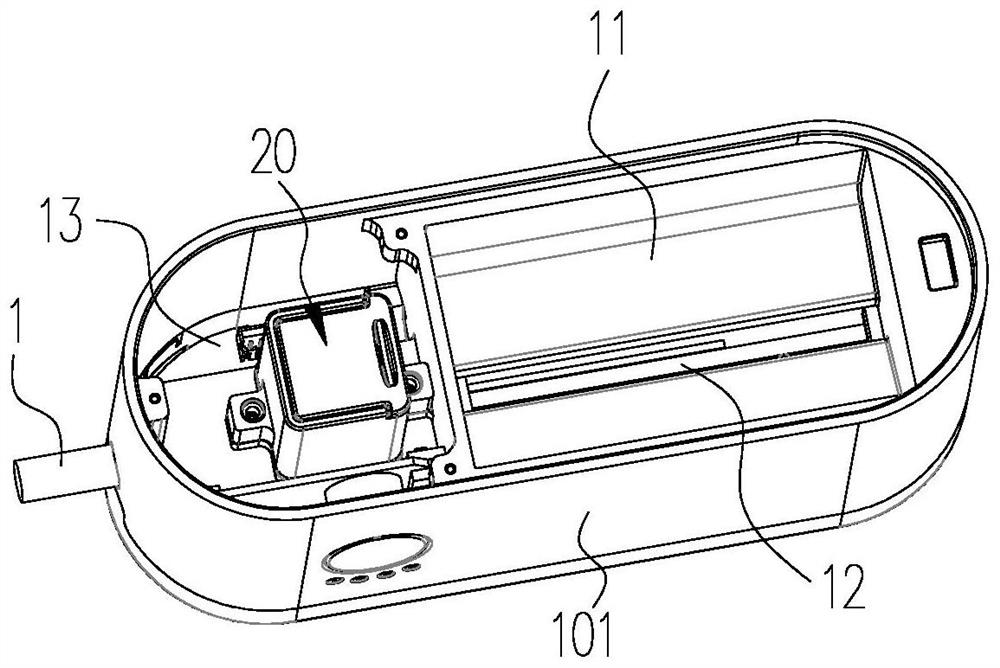

[0070] see Figure 1-Figure 3 and Figure 14 , Embodiment 1 of the present invention provides an additive atomization fumigation device, which is used for cigarette 1, specifically, the additive atomization fumigation device is used to atomize the required additive to generate smoke, and the smoke is used for cigarette 1 Fumigation, the smoke acts on the surface of the cigarette 1 and penetrates into the tobacco inside the cigarette 1, ensuring that the smoking taste of each part of the cigarette 1 is consistent.

[0071] The additives can be flavors and fragrances, smokers, humidifiers, nicotine, additives with medical or medical auxiliary functions, or other additives, or a combination of two or more of the above, or A solution containing at least one of the above additives. It can be understood that the user can adjust the composition of the additive according to actual needs, and the present invention does not limit the composition of the additive.

[0072] The cigarett...

Embodiment 2

[0109] In the second embodiment of the present invention, a fumigation method is provided, which is used in the additive atomization fumigation equipment in the first embodiment to fumigate the cigarette 1 in the first embodiment. The additive atomization smoking device includes a housing 10 and an atomization assembly 20 and a migration assembly 30 installed on the housing 10. A smoke storage chamber 11 is formed on the housing 10, and the smoke storage chamber 11 is used to store cigarettes 1 , the atomization assembly 20 is provided with a liquid storage chamber 210, the liquid storage chamber 210 is used to store the additive, the atomization assembly 20 is used to atomize the additive to form smoke, the migration assembly 30 includes a migration piece 31, and the migration piece 31 is used to move the smoke The cigarette branch 1, the migration member 31 can carry the cigarette branch 1 to move between the first position and the second position, and the smoking method incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com