Preparation method and equipment of konjac glucomannan gel with high water retention

A technology of konjac glucomannan and glucomannan, which can be used in food ingredients as a gelling agent, food ultrasonic treatment, food heat treatment and other directions, can solve the problems of low water retention and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

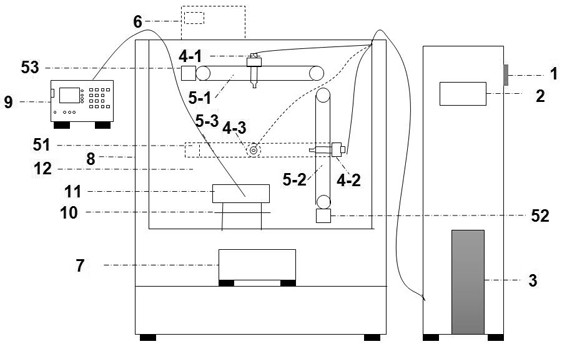

Method used

Image

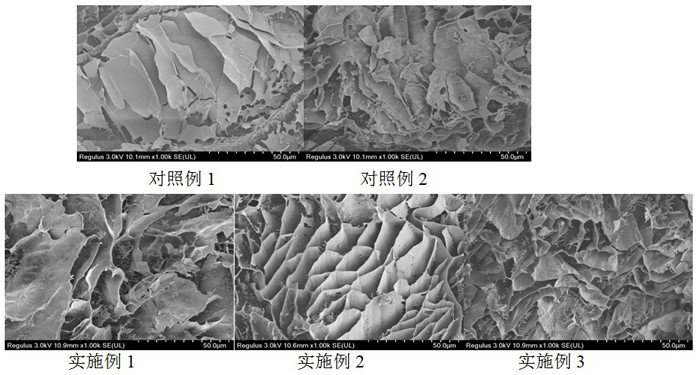

Examples

Embodiment 1

[0037] 100W power three-way orthogonal ultrasonic assisted freezing: refer to the control example to prepare konjac gel, use ultrasonic assisted freezing gel in the freezing pool at -30 ℃ until the central temperature reaches -18 ℃, then turn off the ultrasonic wave, the ultrasonic frequency is 20kHZ, the power density 10W / L, ultrasonic time 5s, intermittent time 5s, frozen in the freezing pool for 12h, and thawed at 25°C for 12h. The measurement items refer to Comparative Example 1.

Embodiment 2

[0039]300W power three-way orthogonal ultrasonic assisted freezing: refer to the control example to prepare konjac gel, use ultrasonic assisted freezing gel in the freezing pool at -30 ℃ until the central temperature reaches -18 ℃, then turn off the ultrasonic wave, the ultrasonic frequency is 20kHZ, the power density 30W / L, ultrasonic time 5s, intermittent time 5s, frozen in the freezer for 12h, thawed at 25°C for 12h. The measurement items refer to Comparative Example 1.

Embodiment 3

[0041] 400W power three-way orthogonal ultrasonic assisted freezing: refer to the control example to prepare konjac gel, use ultrasonic assisted freezing gel in the freezing pool at -30 ℃ until the central temperature reaches -18 ℃, then turn off the ultrasonic wave, the ultrasonic frequency is 20kHZ, the power density 40W / L, ultrasonic time 5s, intermittent time 5s, frozen in the freezer for 12h, thawed at 25°C for 12h. The measurement items refer to Comparative Example 1.

[0042] Table 1 Time comparison of different treatment groups passing through the ice crystal formation zone

[0043]

[0044] Table 2 Comparison of water separation rate and water holding capacity of different treatment groups

[0045]

[0046] Table 3 Comparison of gel strength in different treatment groups

[0047]

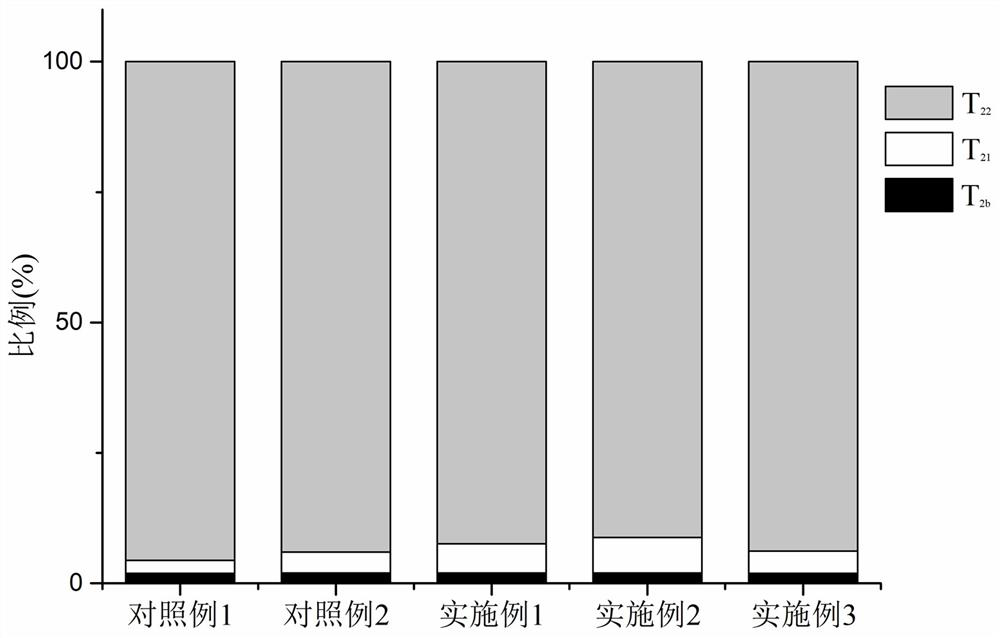

[0048] Table 4 Comparison of moisture distribution in different treatment groups

[0049]

[0050] Note: Different lowercase letters in the same column indicate significant d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com