Compound fermented soybean milk and preparation method thereof

A compound fermentation and soybean milk technology, applied in the direction of food science, etc., can solve problems such as poor taste, single nutritional content, and failure to be favored by consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] single-factor experiment

[0056] 1. To investigate the effect of the ratio of soybean flour and black soybean flour on the sensory evaluation of compound fermented soybean milk

[0057] Prepare 1000mL of compound fermented soybean milk, fixed soybean powder mass 400g, white sugar 85g, stabilizer 3168 5g, light cream 30g, Lactobacillus chuanxiong 1g, the temperature of the first batch is 45℃, the time is 4min, the second batch of batch The temperature is 65°C, the time is 10 minutes, the homogenization pressure is 30MPa, the high temperature sterilization temperature is 85°C, the time is 15min, cooled to 42°C, the fermentation temperature is 42°C, the time is 7h, and the ratio of soybean flour to black soybean flour is investigated. 1:1, 2:1, 3:1, 4:1, 5:1 respectively; the finished products were respectively prepared by the above-mentioned compound fermented soybean milk preparation process, and then sensory evaluation was carried out, the results are shown in figure...

Embodiment 2

[0105] Response surface optimization experiment

[0106] Through the comparison of single factor analysis experiments, three representative single factors were selected, and a three-factor three-level response surface experiment was designed according to the principle of central combination (BoxBehnken) experiment design, with ① fermentation time (h) and ② stabilizer Added amount (g), ③ light cream added amount (g) were used as three factors, and the sensory score of compound fermented soybean milk was used as the response value, and a three-factor and three-level response surface experiment was designed accordingly. The experimental factors and level settings are shown in Table 6.

[0107] Table 6 Response surface test factor levels

[0108]

[0109] On the basis of the above, use the software Design-Expert 8.0.6.1 for making response surface to analyze, and use the fermentation time (X 1 ), the amount of stabilizer added (X 2 ), the amount of light cream added (X 3 ) ...

Embodiment 3

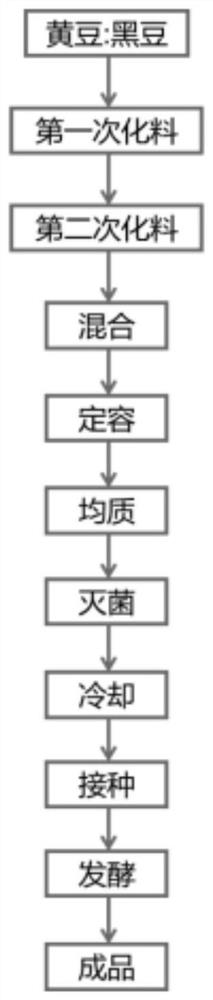

[0122] Prepare 1000mL of compound fermented soybean milk

[0123] S1: Weigh 300g of soybean powder, 100g of black soybean powder, 85g of white sugar, 5g of stabilizer 3168, 30g of light cream, and 1g of Lactobacillus kawaii;

[0124] S2: Mix the weighed soybean powder and black soybean powder to obtain mixed soybean powder, add half of the weighed white sugar to the mixed soybean powder, then mix evenly, and stir the material in a water bath for 4 minutes at 45°C to obtain the mixed soybean powder. slurry;

[0125] S3: Add the remaining white sugar, the weighed stabilizer and the weighed whipped cream to the mixed slurry in S2, mix well, and stir in a water bath at 65°C for 10 minutes to obtain the second mixed slurry material;

[0126] S4: adding water to the second mixed slurry in S3 to make the volume to 1000mL to obtain mixed soybean milk;

[0127] S5: Homogenize the mixed soymilk in S4 twice under a homogenization pressure of 30 MPa, then perform high-temperature steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com