Cutting piece cutting die storage management system and storage management method thereof

A management system and die cutting technology, which is applied in the field of cutting die storage management system, can solve the problems of inconvenient calculation, arbitrary storage of die dies, time-consuming and laborious management of management personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

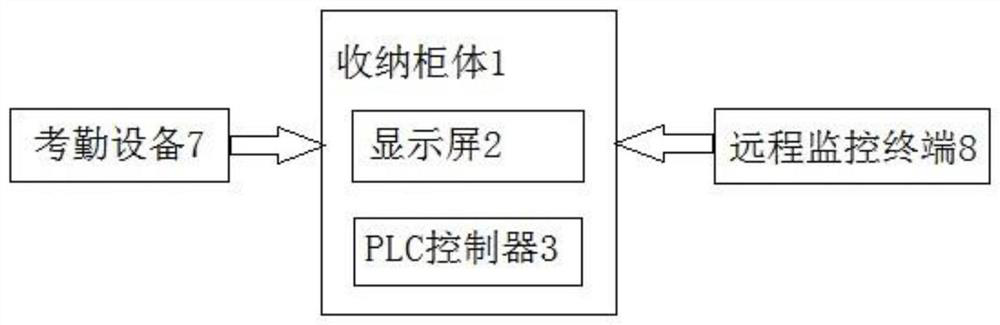

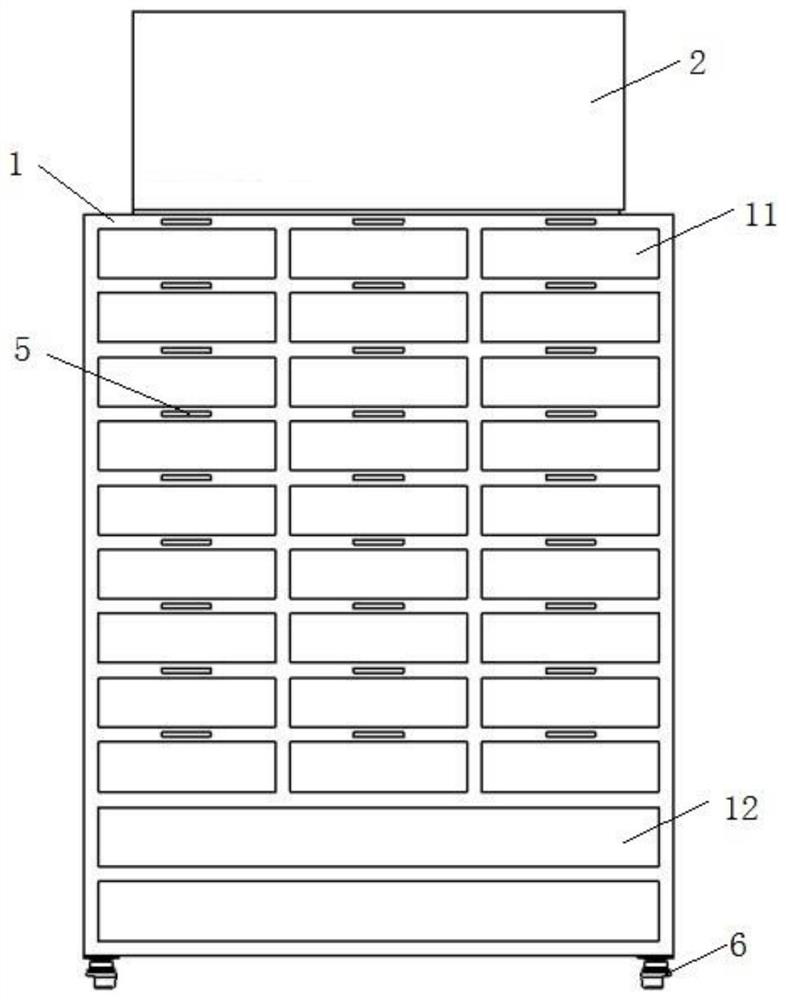

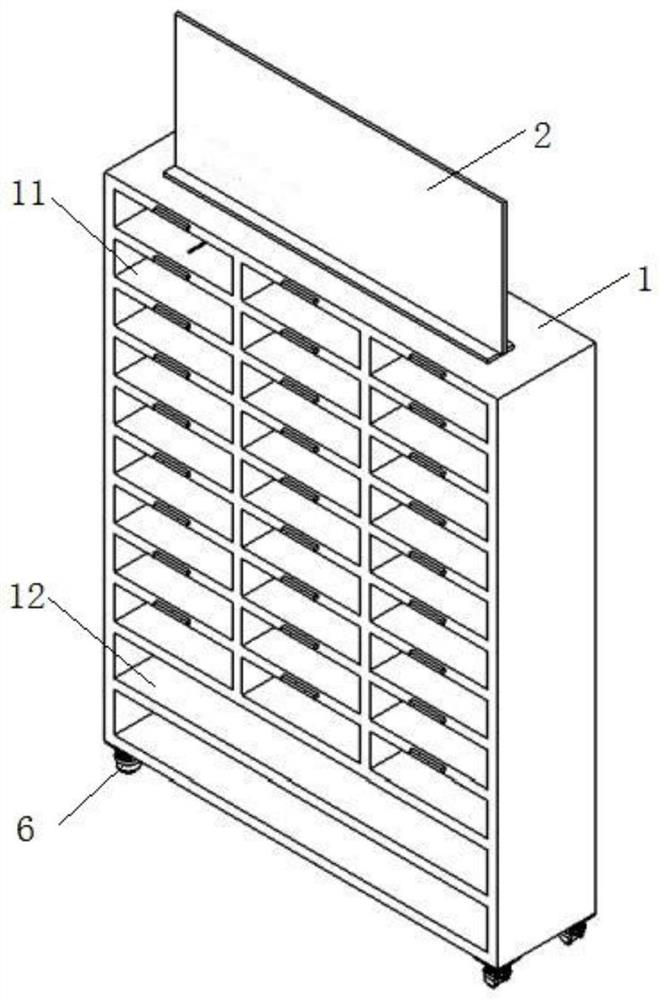

[0065] Such as Figure 1-4 As shown, the present invention discloses a storage and management system for cutting dies, including a storage cabinet 1, a display screen 2, a PLC (Programmable Logic Controller, programmable logic controller) controller 3, and several metal sensors 4 and Cutting die label (not shown), where:

[0066] The storage cabinet 1 includes several small storage compartments 11 and large storage compartments 12 for storing several cutting dies of different specifications (not shown);

[0067] Several die-cutting labels are correspondingly pasted on the die-cutting dies, and are used to label the names and / or models of the die-cutting dies;

[0068] A plurality of the metal sensors 4 are correspondingly arranged in the plurality of the small storage compartments 11 and the large storage compartments 12, and are electrically connected with the PLC controller 3, and are used to sense the taking time and return of the plurality of die cutters. Time and sent t...

Embodiment 2

[0089] Such as Figure 5 As shown, the present invention additionally discloses a cut piece die storage management method, using the above cut piece die storage management system for storage management, including the following steps:

[0090] Step 1: The display screen 2 displays the cutting die information of the corresponding cutting piece when the cutting machine production needs a certain cutting die;

[0091] Step 2: The staff takes the corresponding cutting die from the storage cabinet 1 according to the cutting die information, and proceeds to step 5 if it is taken correctly; if it is wrong, proceeds to step 3;

[0092] Step 3: When the staff takes the wrong die, the warning light 5 and the voice alarm will give an audible and visual alarm and an error prompt will be displayed on the display screen 2;

[0093] Step 4: When the staff takes the correct die, the warning light 5 and the voice alarm stop alarming, and the system returns to normal;

[0094] Step 5: The meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com