Device and method for monitoring stripping of protective film for semiconductor substrate

A monitoring device and protective film technology, used in semiconductor/solid-state device manufacturing, measurement devices, optical device exploration, etc., can solve problems such as peeling, and achieve the effect of excellent productivity and commerciality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

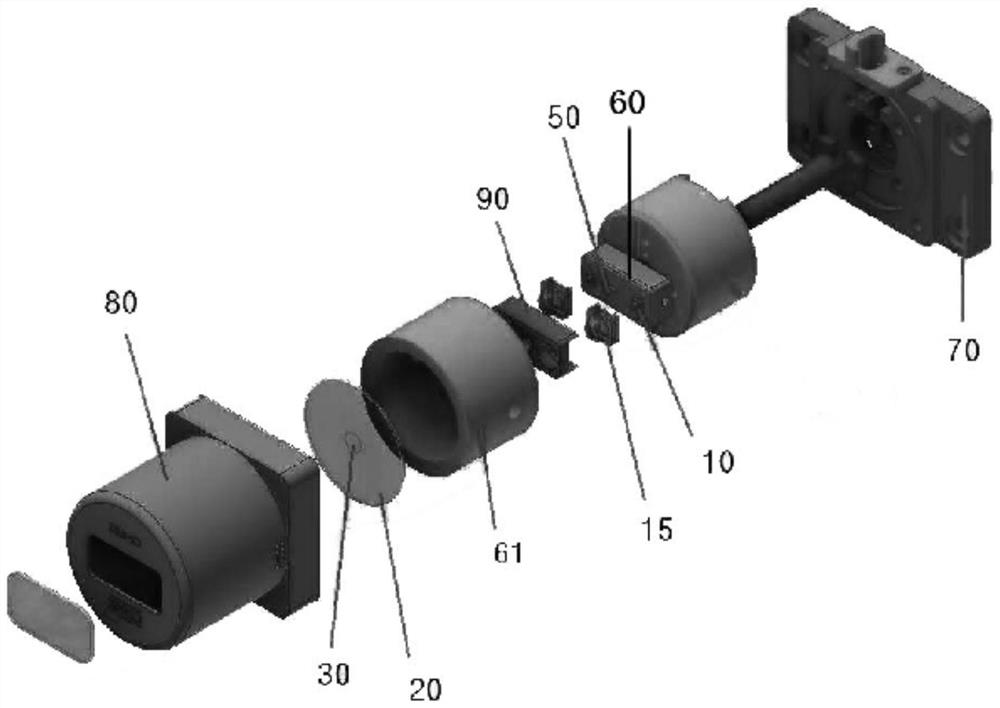

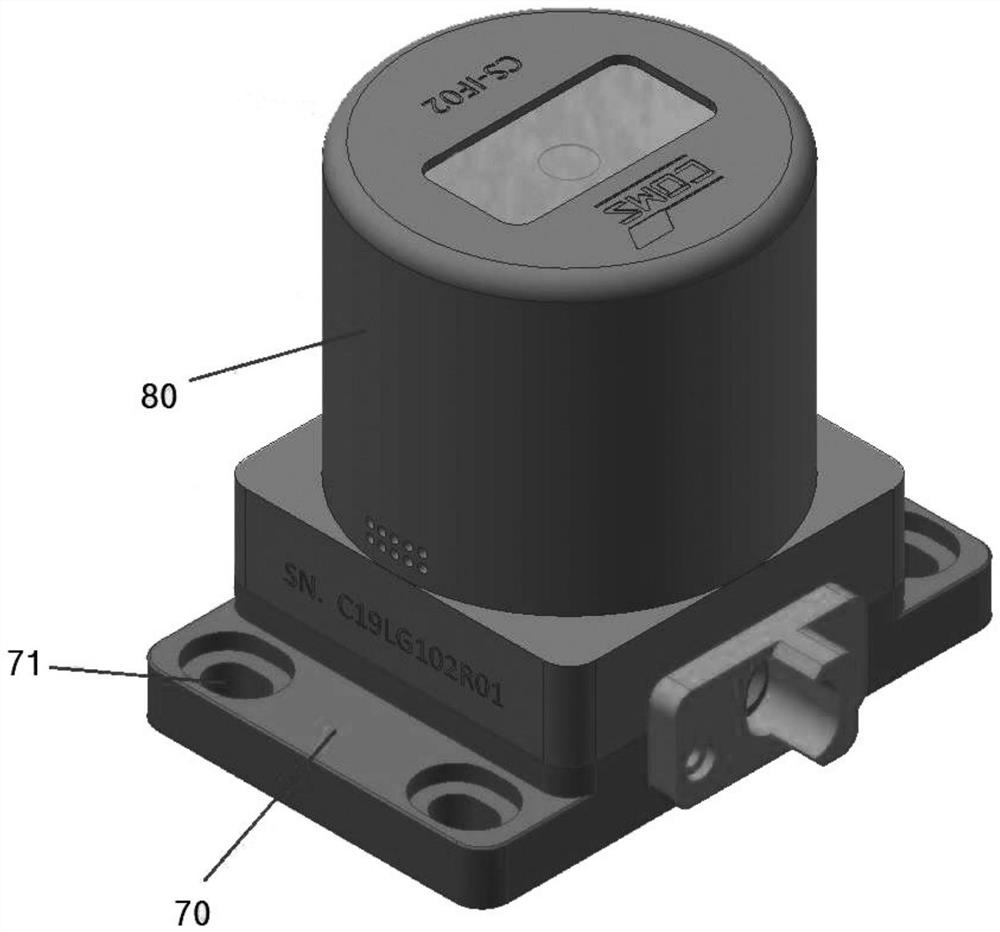

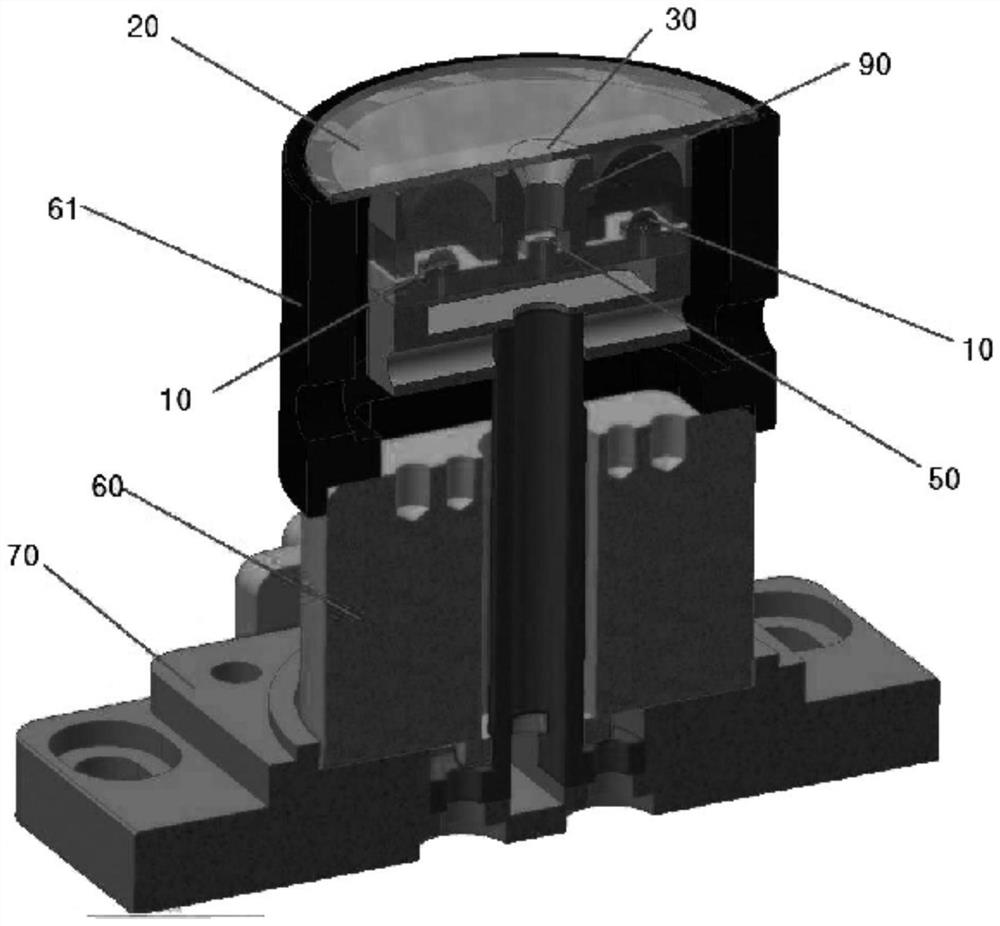

[0046] like Figure 1 to Figure 4 As shown, the semiconductor substrate protective film peeling monitoring device in this embodiment includes a light emitting device 10 , a first polarizer 20 , a second polarizer 30 , a light receiving sensor 50 and a control unit 60 .

[0047] like figure 1 As shown, the first polarizer 20 and the second polarizer 30 can form a circular plate shape, and the second polarizer 30 is located at the center.

[0048] The light-emitting device 10 irradiates light toward the substrate T, that is, the object to be photographed; the first polarizer 20 is located in front of the light-emitting device 10, between the light-emitting device and the substrate, and converts the light generated by the light-emitting device 10 into linearly polarized light, which is directed toward the object to be photographed. incident.

[0049] The second polarizer 30 is perpendicular to the first polarizer 20 , and is located between the substrate T and the light sensor 50...

Embodiment 2

[0075] Figure 9 It is a composition diagram of the monitoring device for whether the protective film for the semiconductor substrate is peeled off in the second embodiment of the present invention;

[0076] Figure 10a and b are diagrams illustrating the polarization cutting effect in Example 2 of the present invention; Figure 10a is the image obtained under non-polarized illumination; Figure 10b It is an image with reflected light removed. The portion removed from the polyester film appears dark due to the removed reflected light, but the portion attached to the polyester film is elliptically polarized, and the light passes through the filter to appear bright.

[0077] Figure 11 It is a partial configuration diagram of a device for monitoring whether or not a protective film for a semiconductor substrate has been peeled in the second embodiment of the present invention.

[0078] like Figure 9 to Figure 11 As shown, whether the semiconductor substrate protective film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com