Method for verifying discharge of lithium ion battery and heat production of connecting piece of lithium ion battery

A technology of lithium ion battery and verification method, which is applied in the field of lithium ion battery heat generation, and can solve the problems of reducing battery rate discharge temperature rise and not considering battery discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

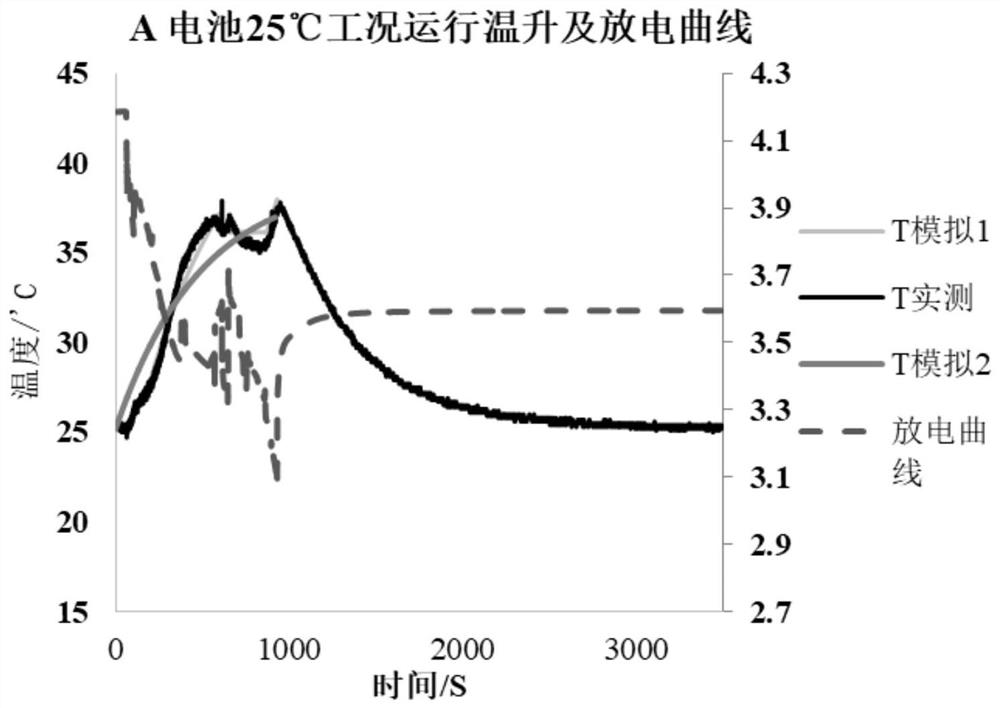

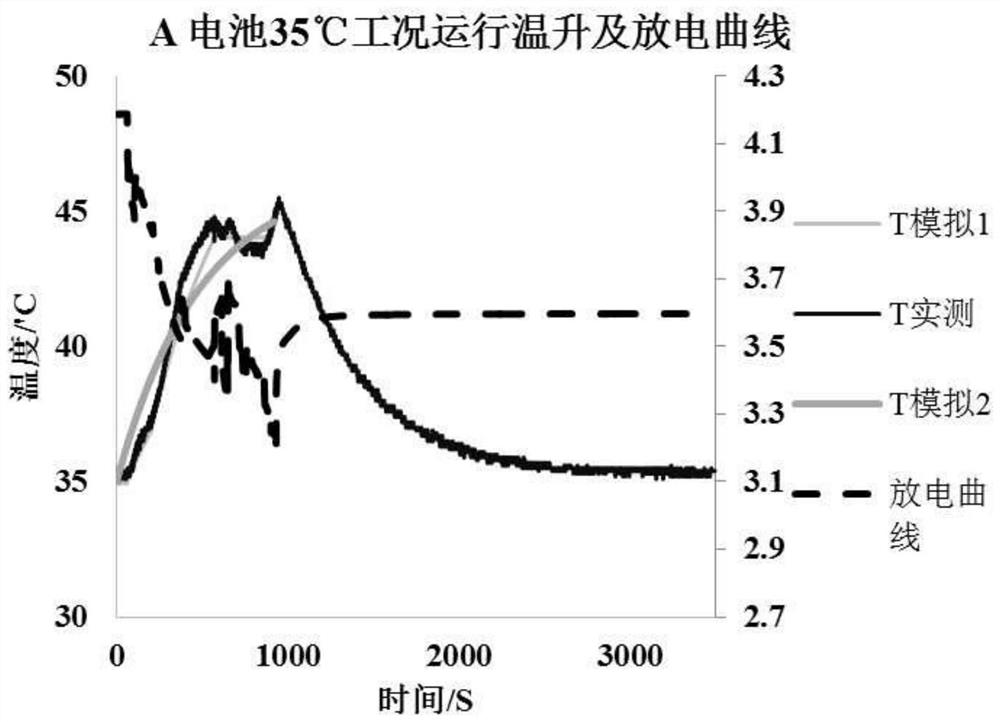

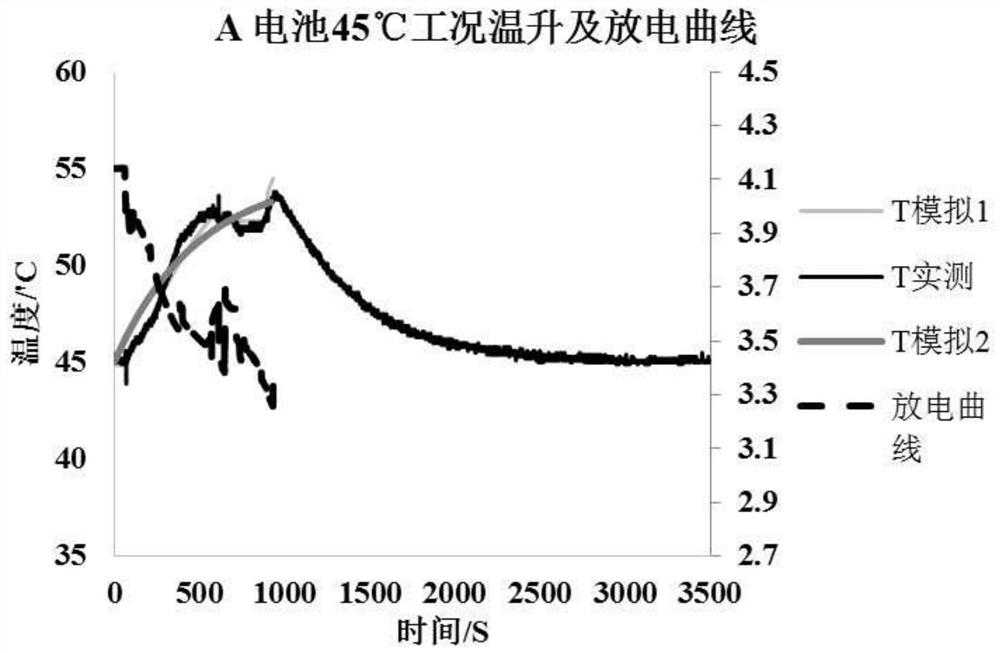

[0036] Embodiment: A method for verifying heat generation of a lithium-ion battery discharge and its connectors in this embodiment includes the following steps:

[0037] (1) Put the lithium-ion battery in a constant temperature, natural convection environment. The temperature range required by the constant temperature includes -50°C to 60°C to facilitate obtaining the required parameters of the battery under different temperature states. The natural convection environment requires that all sides of the battery be in a state of natural convection, only allowing no more than 2% of the area to be in contact with the heat insulating material, and the battery support is in a suspended state.

[0038] (2) Carry out charge and discharge tests on lithium-ion batteries under different temperature conditions. First, discharge the lithium-ion batteries to ensure that the contact resistance voltage drop between the battery and the test line is not collected by the voltage acquisition line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com