Armrest horizontal limiting device, seat and automobile

A horizontal limit and armrest technology, which is applied in the direction of armrests, vehicle seats, special positions of vehicles, etc., can solve the problems affecting the comfort of passengers and the inability to maintain the level of armrests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

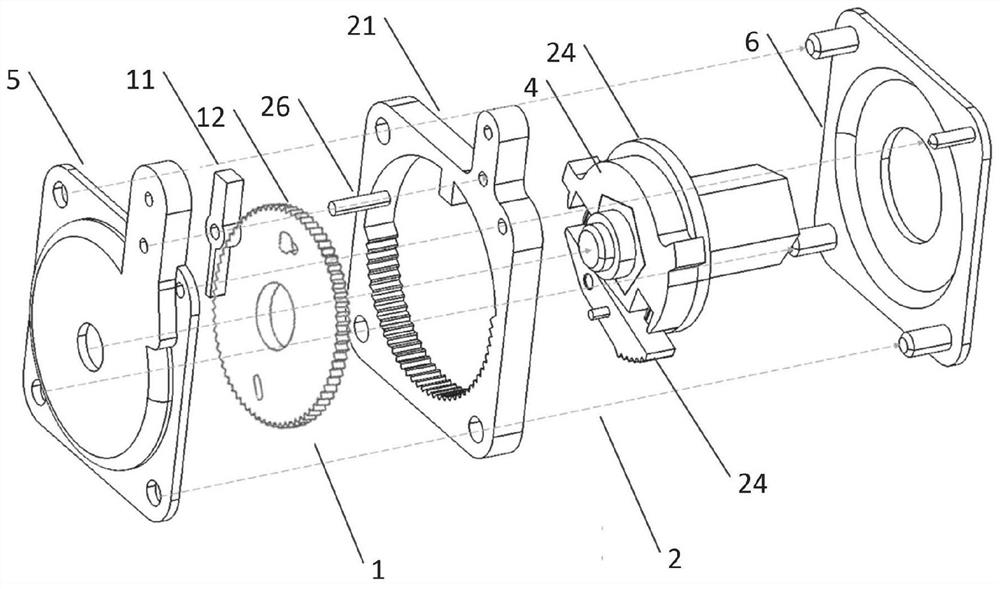

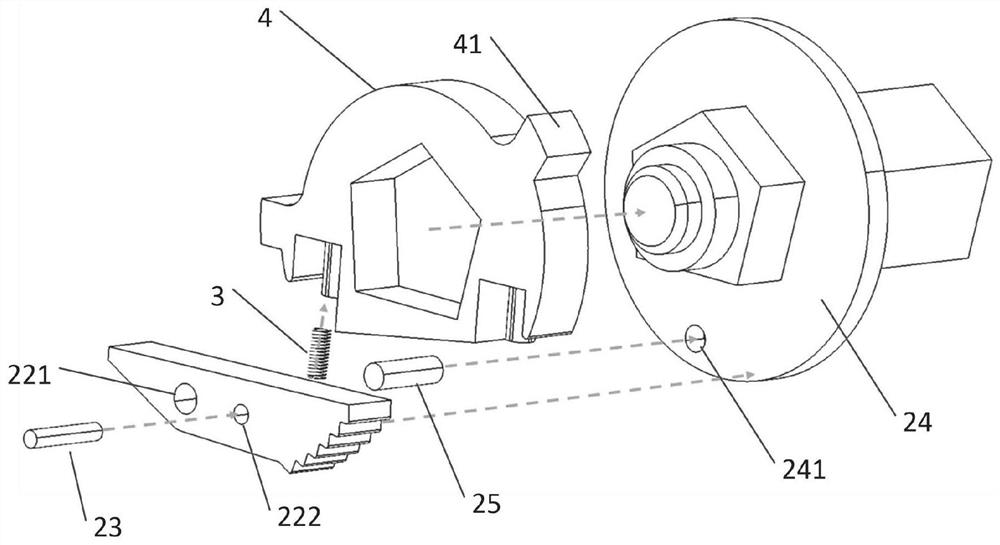

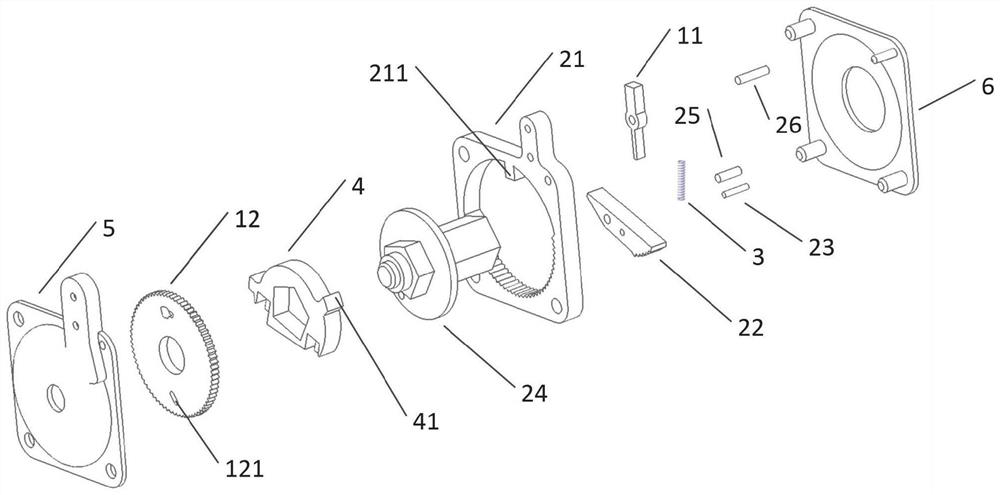

[0035] Such as Figure 1-3As shown, a handrail level limiting device, the limiting device is used to be assembled in the armrest, so that the armrest can be adjusted to maintain a horizontal state, the limiting device includes a gravity component 1 and a ratchet component 2, the gravity component 1 is used for Control the unlocking and locking of the ratchet assembly 2, the ratchet assembly 2 includes a ratchet lock plate 21, a ratchet swing tooth 22, a ratchet swing tooth unlocking shaft 23 and a main shaft 24, the ratchet swing tooth 22 meshes with the ratchet lock plate 21, and the ratchet lock plate 21 is used for Control the rotation and stop of the armrest, the armrest is connected to the main shaft 24 in rotation, the ratchet swing tooth 22 is connected to the main shaft 24 in rotation, the gravity assembly 1 includes a gravity lock 11 and a gravity lock disc 12, and the gravity lock 11 is rotatably connected to the ratchet lock disc 21, When the gravity lock 11 is in t...

Embodiment 2

[0061] A seat, characterized in that it includes an armrest and the armrest level limiting device as described in Embodiment 1. Taking the passenger’s seating position as the reference, the left armrest of the seat corresponds to the position close to the passenger’s left hand, and the right armrest of the seat corresponds to the position of the passenger’s left hand. Close to the passenger's right hand position, the armrest level limiting device described in Embodiment 1 is installed on the left armrest of the seat, and the main shaft 24 protruding from the round hole on the inner shell 6 is used to install on the left side of the seat The end face, that is, the central axis of the main shaft is perpendicular to the left end face of the seat, the inner shell 6 is the side close to the seating position of the seat, and the outer shell 5 is the side away from the seating position of the seat; when the When the armrest level limiting device is installed on the right armrest of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com