Rivet feeding mechanism for automatic drilling and riveting system and manufacturing process

An automatic drilling and riveting technology, which is applied in the field of rivet assembly equipment, can solve the problems of inability to realize the orderly arrangement of large quantities of rivets, poor precision, and low work efficiency, so as to reduce labor costs, improve efficiency and accuracy, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

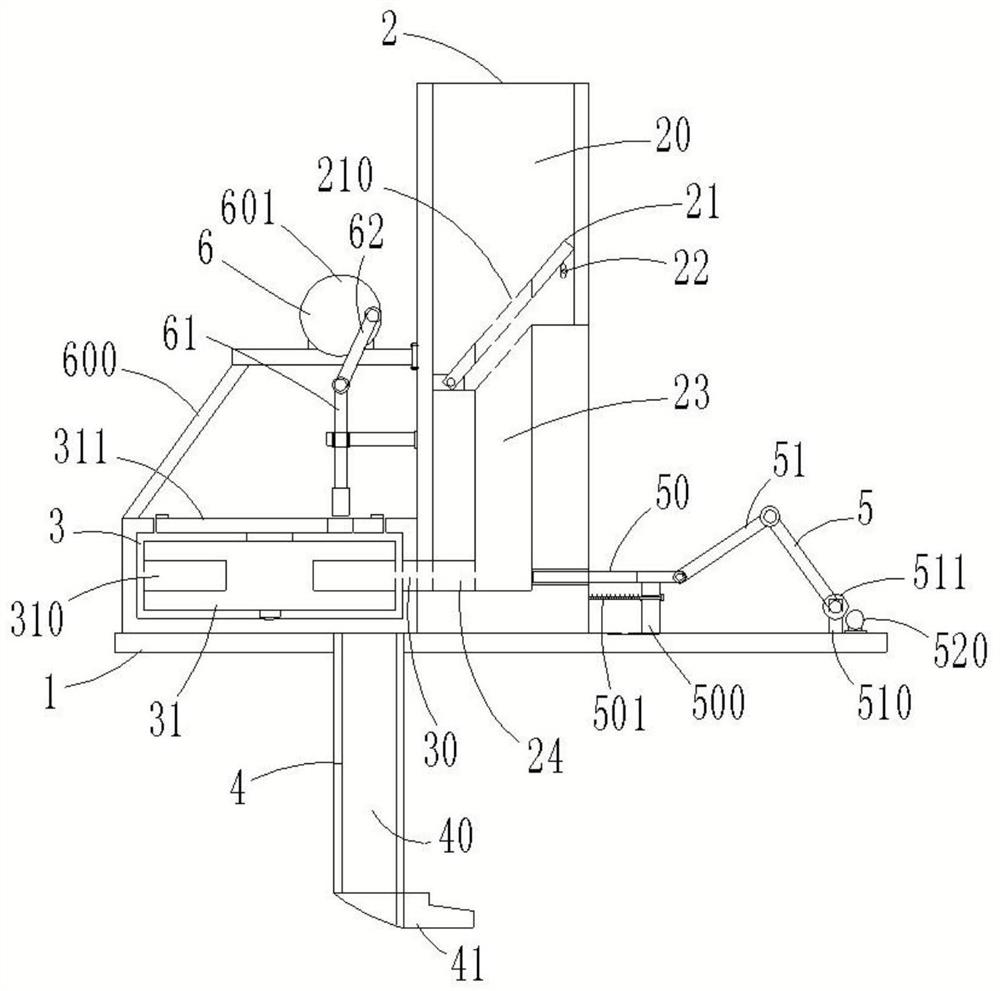

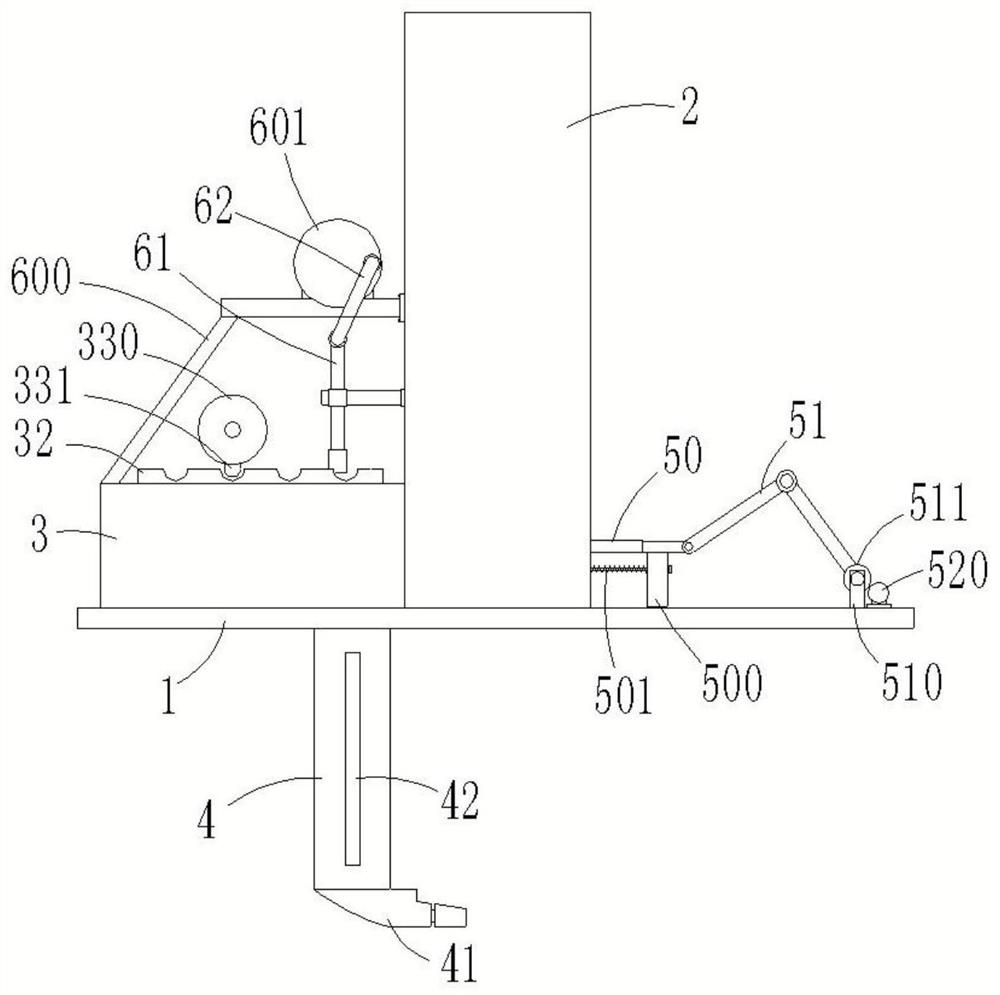

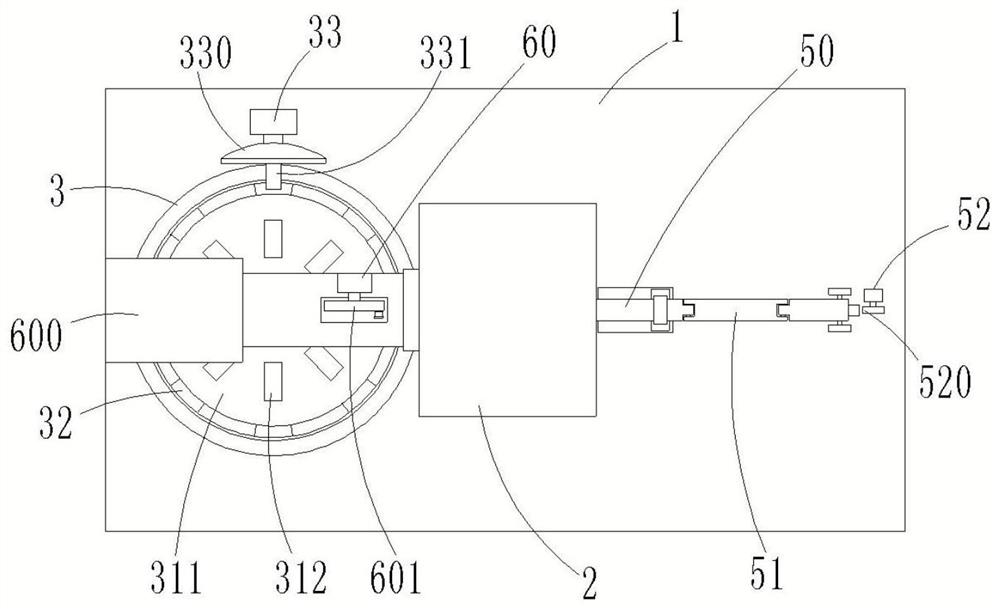

[0039] Embodiment 1: as figure 1 , 2 , A rivet feeding mechanism for automatic drilling and riveting systems shown in 3 and 4, including a mounting plate 1, a nail storage box 2, a conversion box 3, a nail input barrel 4, a first ejector assembly 5, a second ejector Out of the assembly 6 and the controller, the nail storage box 2 is fixedly arranged on the installation plate 1, and the upper end of the nail storage box 2 is provided with a storage cavity 20 and a vibrating plate 21. One end of 21 is articulated with the inner wall of the storage chamber 20, the other end is connected with the storage chamber 20 with a vibrating motor 22, the vibrating plate 21 is provided with a blanking hole 210, and the inner lower end of the nail storage box 2 is vertically provided with a first conveying trough 23. The lower end of the nail storage box 2 is horizontally provided with a first ejection groove 24 that is connected to the first conveying groove 23;

[0040] Such as figure ...

Embodiment 2

[0053] Embodiment 2: as figure 1 , 2 , A rivet feeding mechanism for automatic drilling and riveting systems shown in 3 and 4, including a mounting plate 1, a nail storage box 2, a conversion box 3, a nail input barrel 4, a first ejector assembly 5, a second ejector Out of the assembly 6 and the controller, the nail storage box 2 is fixedly arranged on the installation plate 1, and the upper end of the nail storage box 2 is provided with a storage cavity 20 and a vibrating plate 21. One end of 21 is articulated with the inner wall of the storage chamber 20, the other end is connected with the storage chamber 20 with a vibrating motor 22, the vibrating plate 21 is provided with a blanking hole 210, and the inner lower end of the nail storage box 2 is vertically provided with a first conveying trough 23. The lower end of the nail storage box 2 is horizontally provided with a first ejection groove 24 that is connected to the first conveying groove 23;

[0054] Such as figure ...

Embodiment 3

[0067] Embodiment 3: as figure 1 , 2 , A rivet feeding mechanism for automatic drilling and riveting systems shown in 3 and 4, including a mounting plate 1, a nail storage box 2, a conversion box 3, a nail input barrel 4, a first ejector assembly 5, a second ejector Out of the assembly 6 and the controller, the nail storage box 2 is fixedly arranged on the installation plate 1, and the upper end of the nail storage box 2 is provided with a storage cavity 20 and a vibrating plate 21. One end of 21 is articulated with the inner wall of the storage chamber 20, the other end is connected with the storage chamber 20 with a vibrating motor 22, the vibrating plate 21 is provided with a blanking hole 210, and the inner lower end of the nail storage box 2 is vertically provided with a first conveying trough 23. The lower end of the nail storage box 2 is horizontally provided with a first ejection groove 24 that is connected to the first conveying groove 23;

[0068] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com