Backflow water storage type waterproof structure

A waterproof structure, water storage technology, applied in the direction of the engine seal, engine components, shafts, etc., can solve problems such as damage to the main shaft and bearings, and achieve the effect of improving the waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

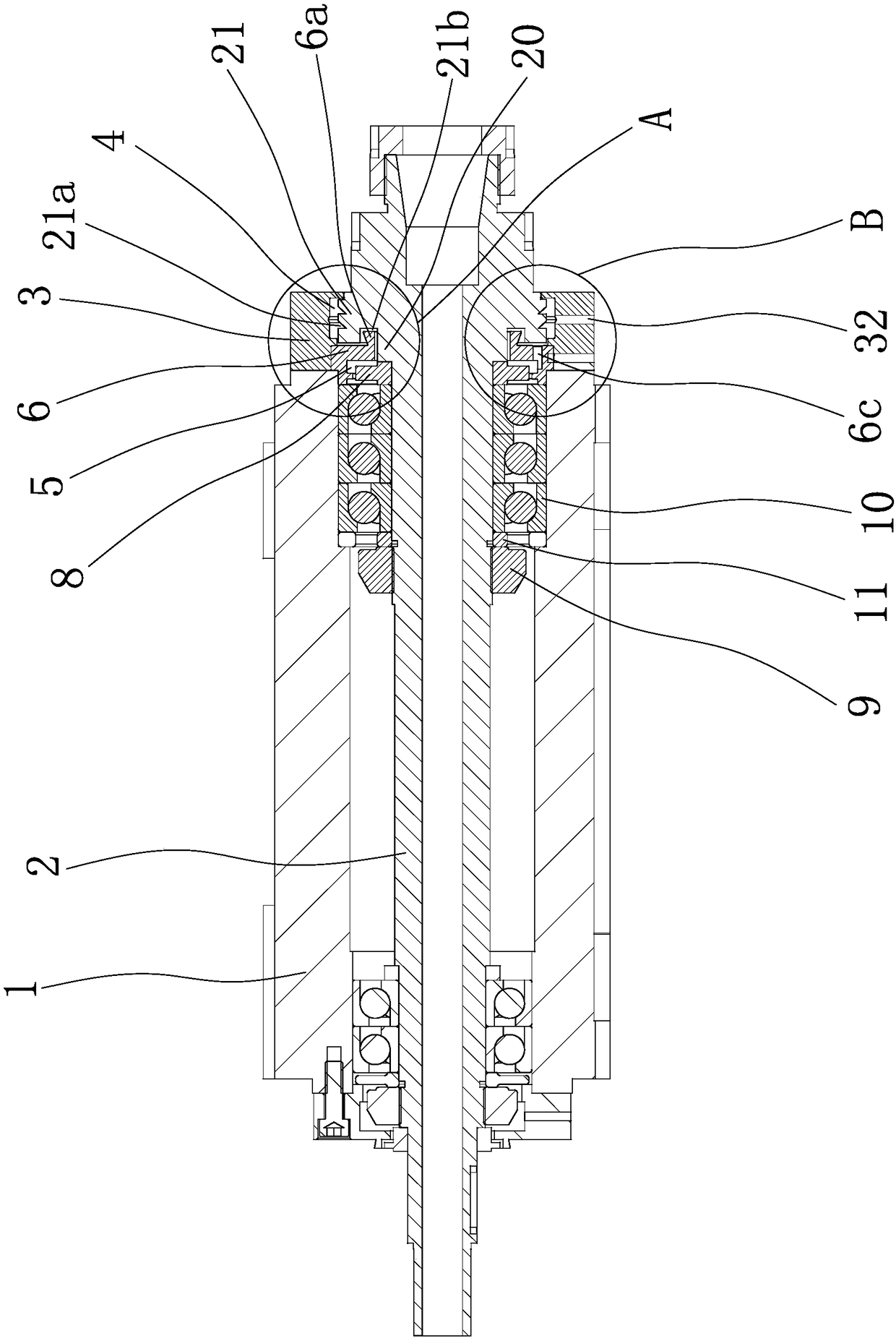

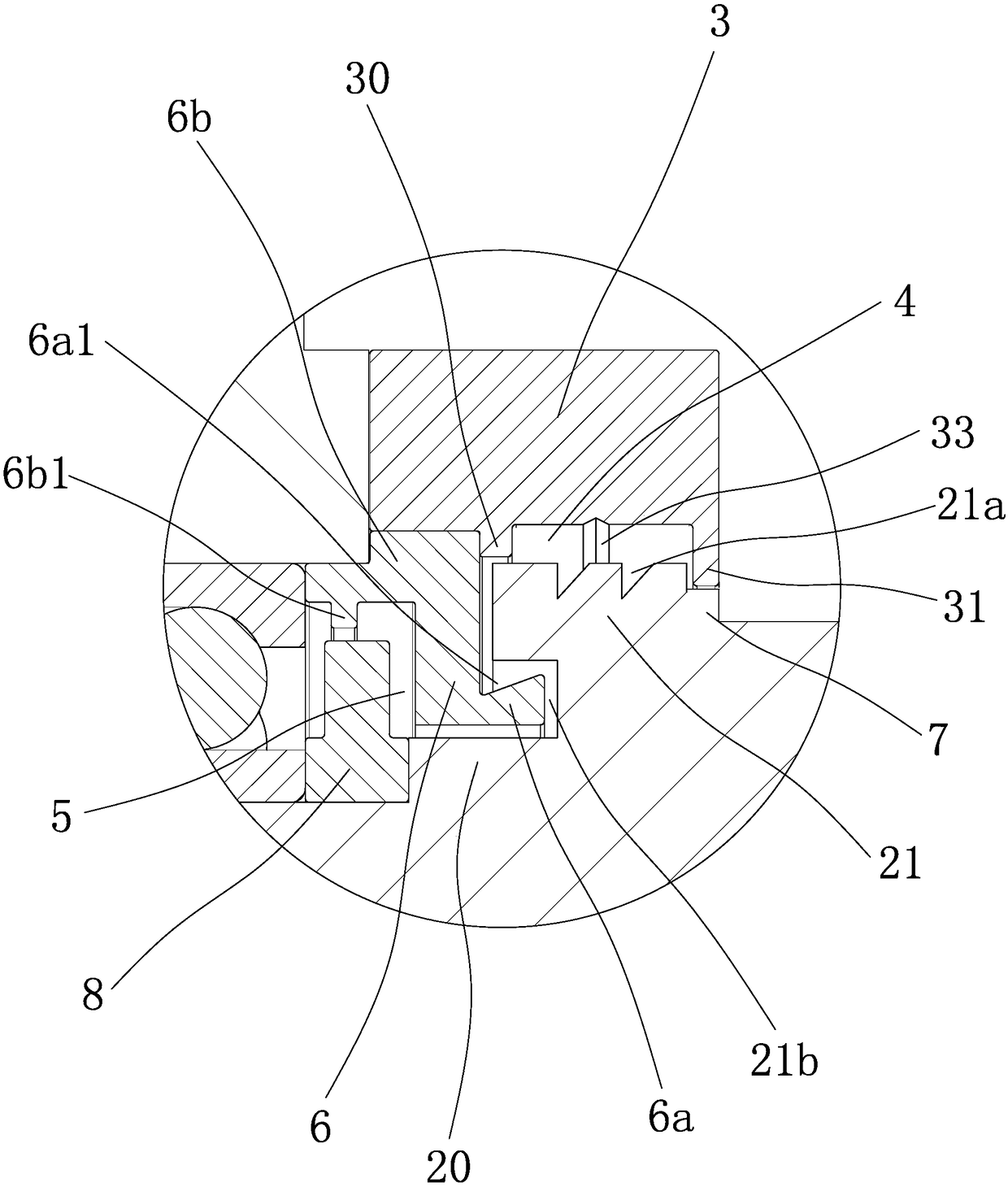

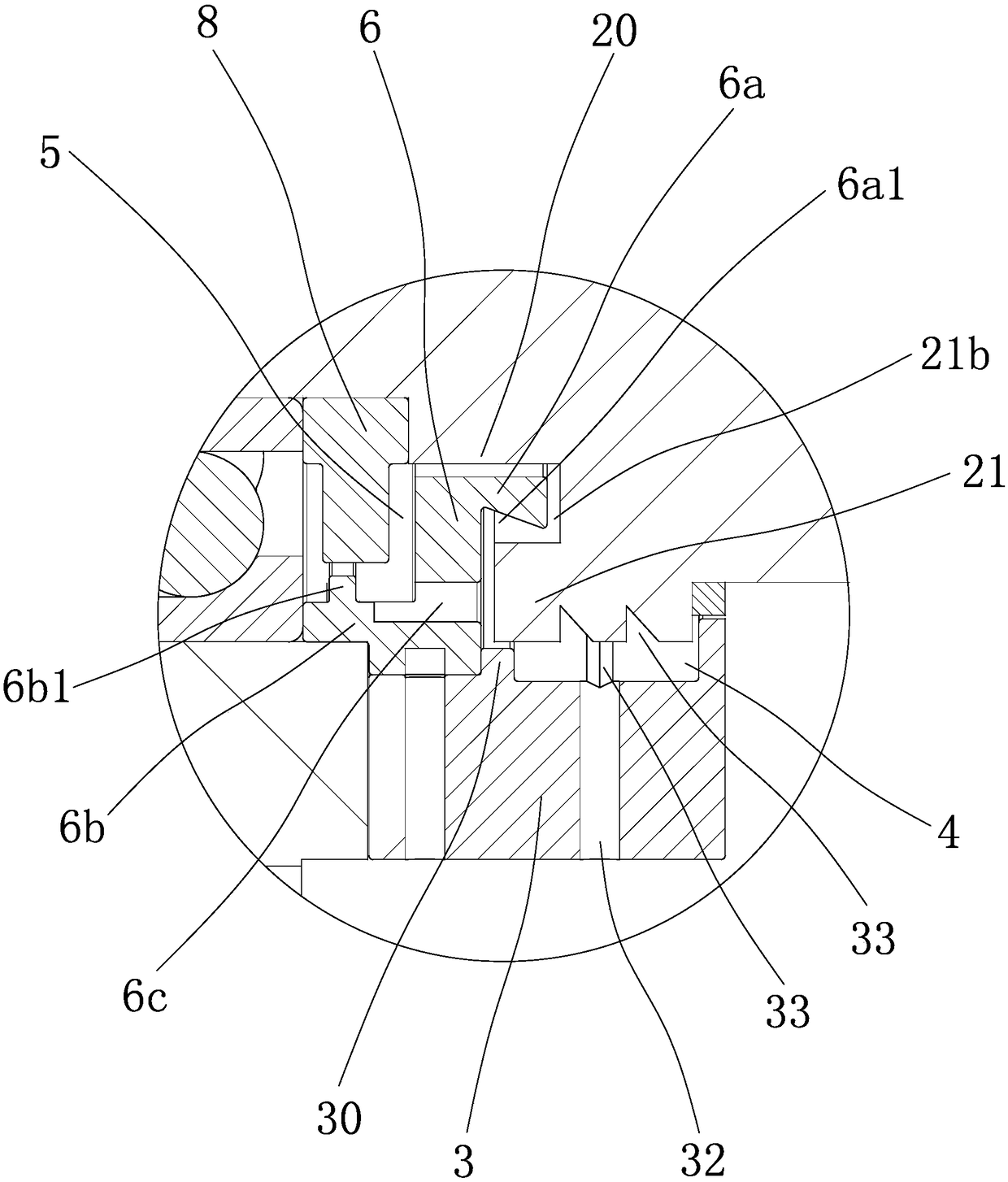

[0022] Such as figure 1 , figure 2 and image 3As shown, it includes a housing 1, a main shaft 2 arranged in the housing 1 and an end cover 3 arranged at one end of the housing 1. The outer peripheral surface of one end of the main shaft 2 has ring-shaped inner bosses 20 and outer bosses. Boss 21, the outer diameter of the outer boss 21 is greater than the outer diameter of the inner boss 20, an outer chamber 4 is formed between the outer peripheral surface of the outer boss 21 and the inner peripheral surface of the end cover 3, the An inner chamber 5 is formed between the outer peripheral surface of the inner boss 20 and the inner peripheral surface of the end cover 3, the outer chamber 4 communicates with the inner chamber 5, and the outer peripheral surface of the outer boss 21 is provided with Centrifugal groove 21a, the inner end surface of the outer boss 21 is provided with a ring-shaped relief groove 21b, the inner chamber 5 has a sealing ring 6 fixed on the end cov...

Embodiment 2

[0027] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that this drainage structure can also be provided with two drainage passages-32 along the radial direction on the outer peripheral surface of the end cover 3, and one of the drainage passages-32 is connected Outer chamber 4 and another drain channel 1 32 communicate with inner chamber 5 , and the side of seal ring 6 opposite to sealing sleeve 8 is provided with drain channel 2 6c communicating with drain channel 1 32 communicating with inner chamber 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com