Fluidized soil backfilling equipment with screening function

A technology of backfilling and screening, which is applied to clay preparation devices, screening, solid separation, etc., can solve the problems of low degree of automation, achieve the effect of improving utilization rate, increasing integration degree and automation level, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

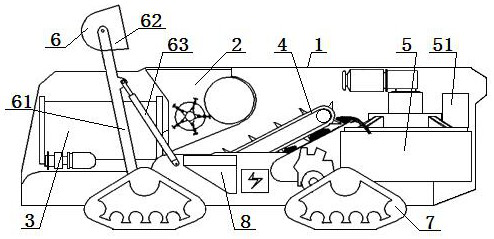

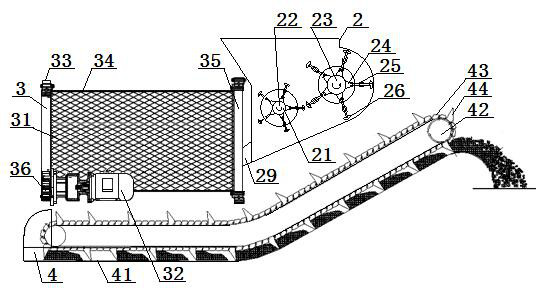

[0049] A fluidized backfill equipment with a screening function, the fluidized backfill equipment includes: a housing 1 and a crushing mechanism 2 arranged in the housing 1, a screening mechanism 3, a chain rake conveying mechanism 4 and a mixing The stirring mechanism 5, the chain rake conveying mechanism 4 and the mixing and stirring mechanism 5 are fixed on the floor in the housing 1, and the discharge end of the chain rake conveying mechanism 4 is arranged above the feeding port of the mixing and stirring mechanism 5, so The screening mechanism 3 is arranged above the feeding end of the chain rake conveying mechanism 4, and the shell 1 on the side of the chain rake conveying mechanism 4 is provided with a cement feeding port 8, and the crushing mechanism 2 is arranged on the screening mechanism 3 Between the mixing and stirring mechanism 5, the discharge port of the crushing mechanism 2 is set facing the inside of the screening mechanism 3, and the feed port of the crushing...

Embodiment 2

[0051] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

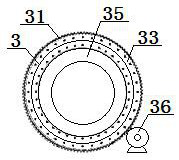

[0052] The screening mechanism 3 is a roller screening mechanism.

[0053] Both sides of the bottom of the housing 1 are respectively provided with two sets of crawler running devices 7, the crawler running devices 7 are driven by hydraulic motors or diesel engines, and the sides of the crawler running devices 7 are connected to the bottom of the housing 1 through hydraulic lifting cylinders. connected.

Embodiment 3

[0055] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0056] The feeding mechanism 6 includes a rotating arm 61 and a hopper 62. Both sides of the housing 1 are respectively connected to the side of the hopper 62 through a rotating arm 61. The lower end of the rotating arm 61 is connected to the side of the housing 1. The side part is rotationally matched, the upper end of the pivoting arm 61 is pivotally matched with the hopper 62 , and the side of the housing 1 is connected with the middle part of the pivoting arm 61 through the pivoting arm cylinder 63 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com