Rapidly-assembled environment-friendly sound insulation plate and assembling method thereof

An assembled, plate technology, applied in the direction of sound insulation, building components, construction, etc., can solve the problems of reduced sound insulation effect of sound insulation boards, long labor hours, and high assembly difficulty, simplifying installation steps, reducing the number of bolt connections, and reducing The effect of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

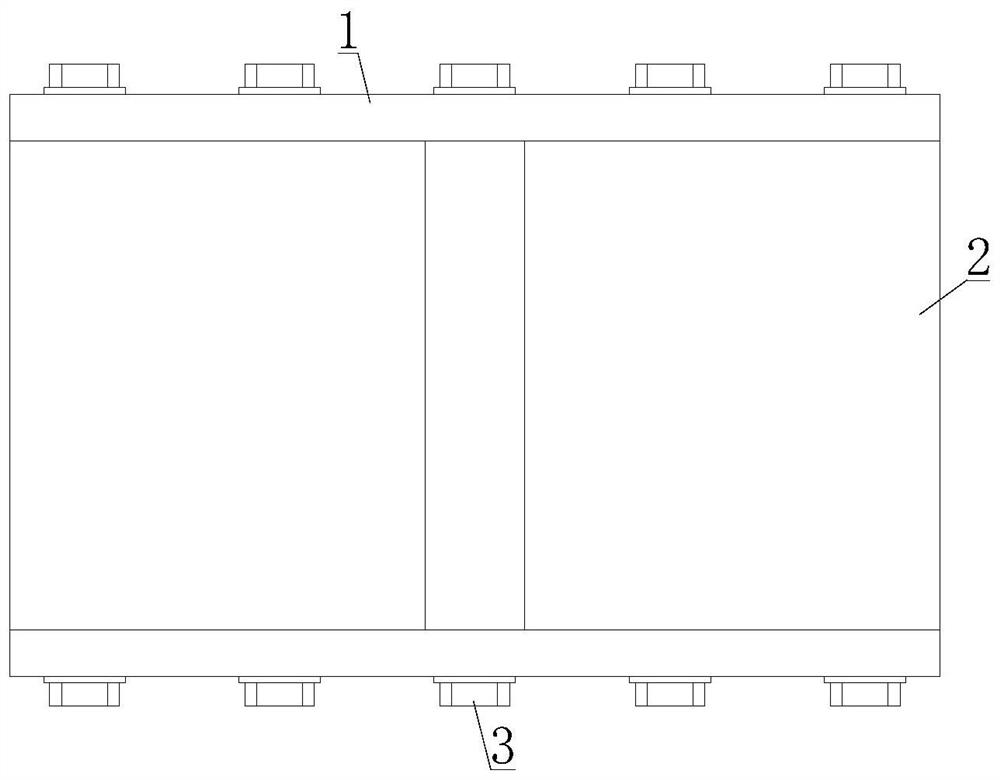

[0030] see figure 1 , a quick-assembled environmentally friendly soundproof board, comprising a board outer frame 1, an assembled board 2 and connecting bolts 3, the inner two ends of the board outer frame 1 are respectively installed with assembled boards 2, and the upper and lower ends of the board outer frame 1 are respectively installed with connecting bolts 3.

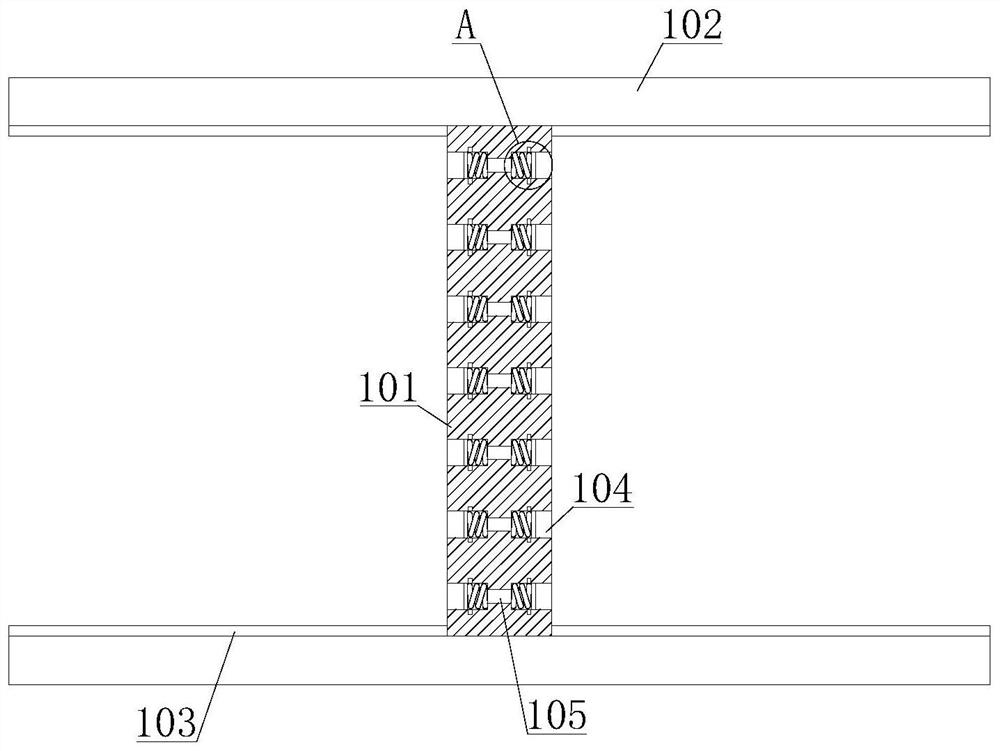

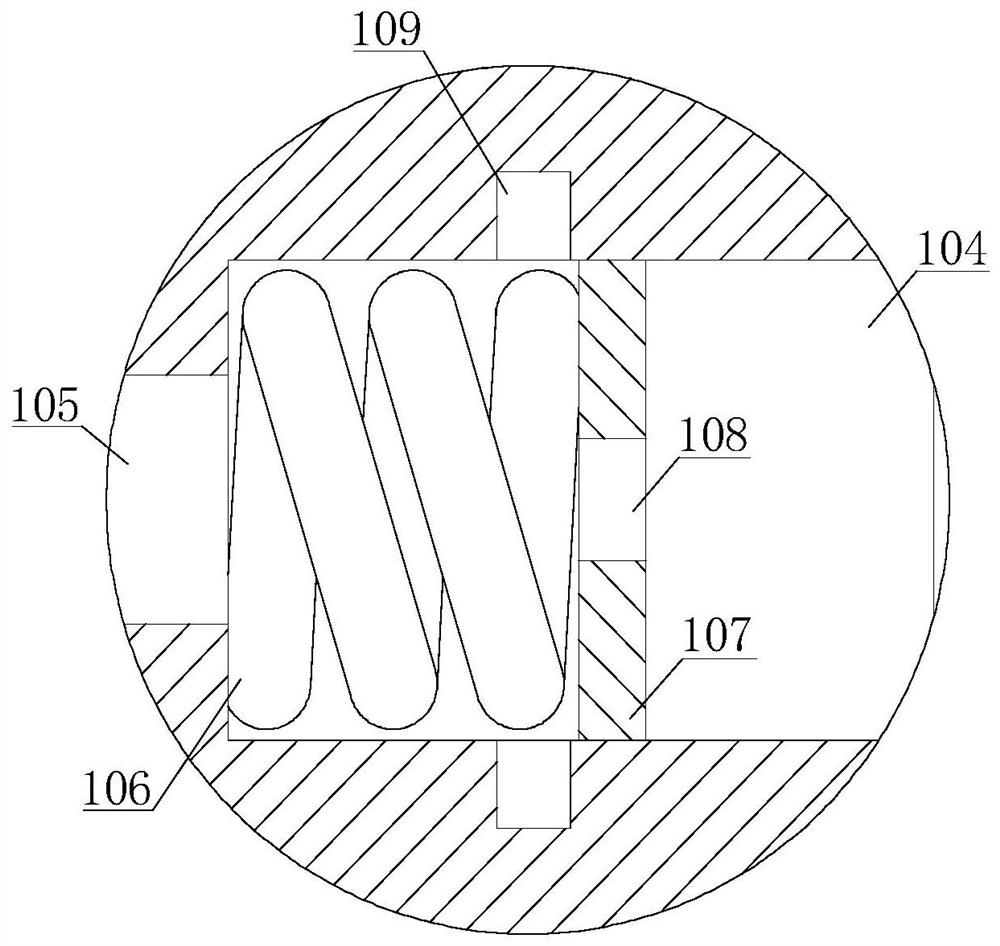

[0031] see Figure 2-Figure 3 The outer frame 1 of the plate includes a central splint 101, a frame splint 102, a clamping slideway 103, an assembly socket 104, a connecting slot 105, a return spring 106, a spring clamping plate 107, a central mounting hole 108 and a buckle groove 109. The upper and lower sides of the splint 101 are respectively provided with a frame splint 102, the inner side of the frame splint 102 is provided with a snap-in slideway 103, the left and right sides of the center splint 101 are respectively provided with an assembly socket 104, and the inner bottom of the assembly socket 104 A co...

Embodiment 2

[0041] see figure 1 , a quick-assembled environmentally friendly soundproof board, comprising a board outer frame 1, an assembled board 2 and connecting bolts 3, the inner two ends of the board outer frame 1 are respectively installed with assembled boards 2, and the upper and lower ends of the board outer frame 1 are respectively installed with connecting bolts 3.

[0042] see Figure 2-Figure 3 The outer frame 1 of the plate includes a central splint 101, a frame splint 102, a clamping slideway 103, an assembly socket 104, a connecting slot 105, a return spring 106, a spring clamping plate 107, a central mounting hole 108 and a buckle groove 109. The upper and lower sides of the splint 101 are respectively provided with a frame splint 102, the inner side of the frame splint 102 is provided with a snap-in slideway 103, the left and right sides of the center splint 101 are respectively provided with an assembly socket 104, and the inner bottom of the assembly socket 104 A co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com