Intelligent automatic feeding operation device applied to rail fastener bolts

A technology of automatic feeding and operation device, applied in the direction of assembly machine, metal processing, metal processing equipment, etc., can solve the problem of unable to realize automatic assembly and disassembly, and achieve the effect of realizing full automation and overcoming unqualified assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

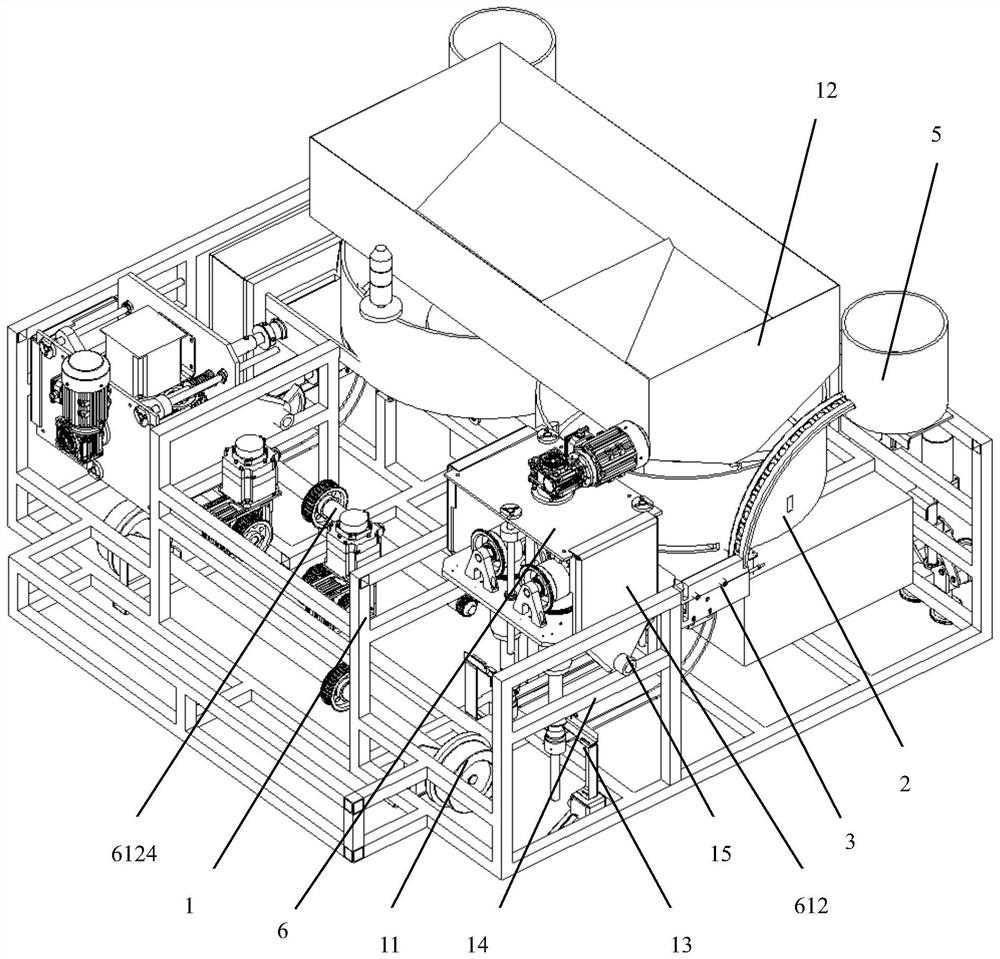

[0039] Such as Figure 1-10 As shown, the embodiment of the present invention provides an intelligent automatic loading operation device for rail fastener bolts. Including the vehicle frame 1, the vehicle frame 1 is provided with a control center, and the bottom of the vehicle frame 1 is provided with a running mechanism 11, the running mechanism 11 is controlled by a motor and an operation center, and the existing technology can be used for this part.

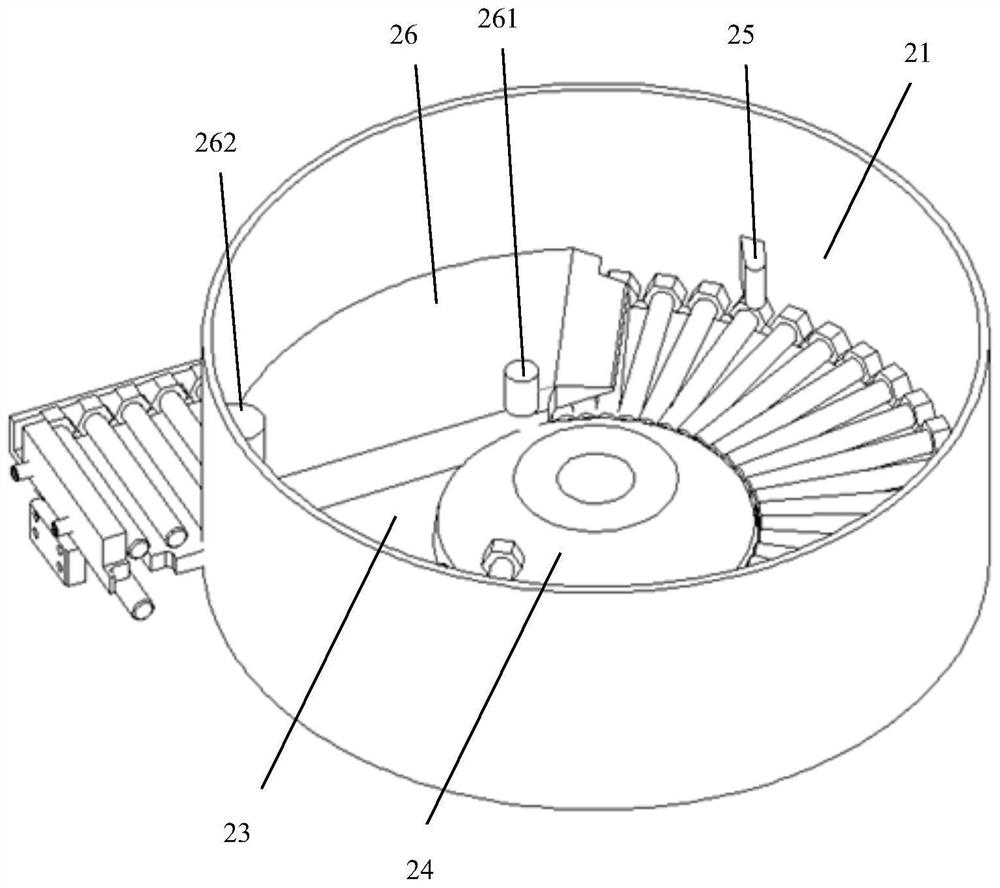

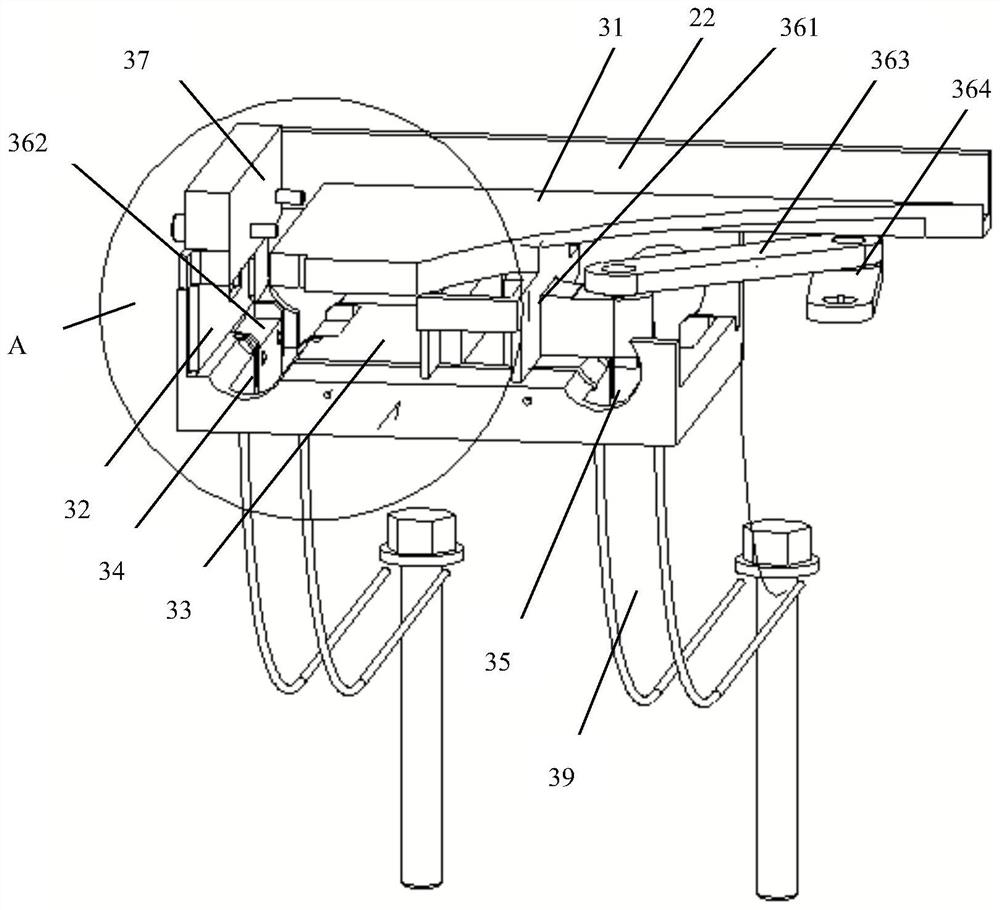

[0040] The vehicle frame 1 is provided with a first unloading mechanism 2 , a material distributing mechanism 3 , a pushing mechanism 4 , a second unloading mechanism 5 and an electric wrench 6 capable of lifting and swinging. Among them, the first unloading mechanism 2 and the second unloading mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com