Recycling container and cleaning equipment

A container and storage cavity technology, which is applied to cleaning equipment, cleaning machinery, suction filters, etc., can solve the problems of difficult cleaning of recycling containers, and achieve stable and good filtering effect, easy cleaning, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

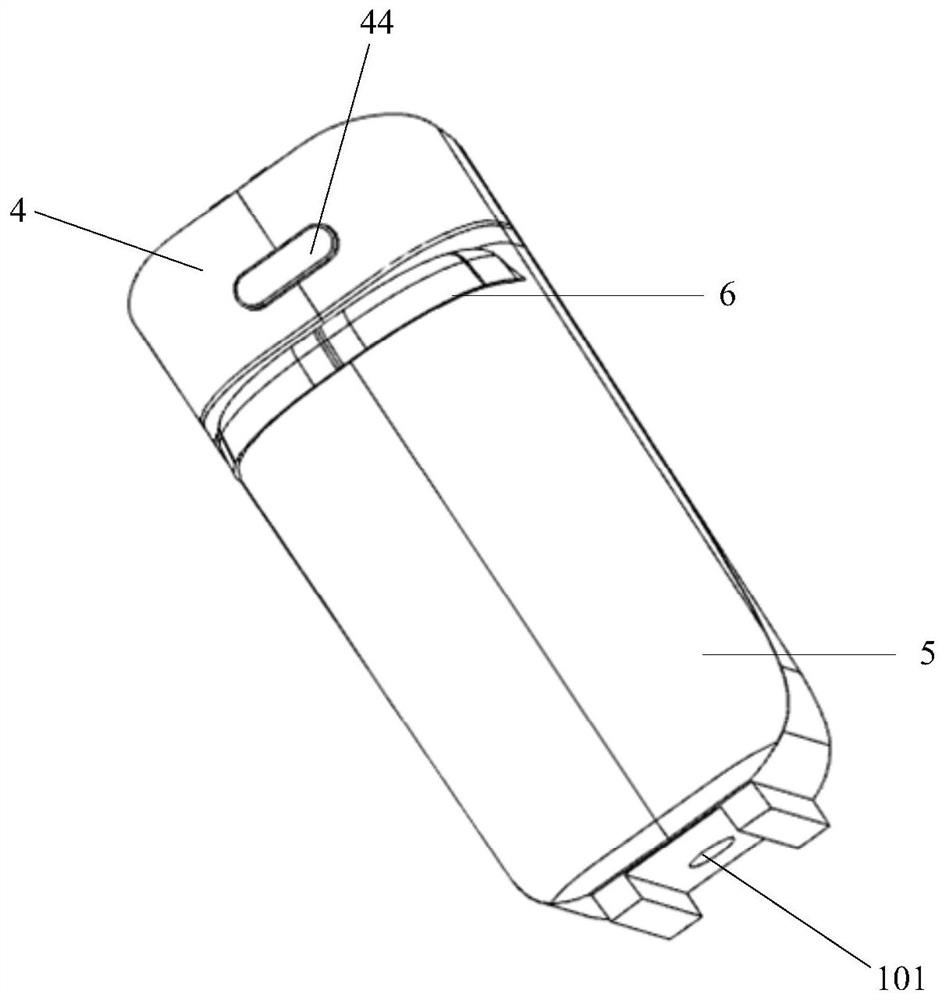

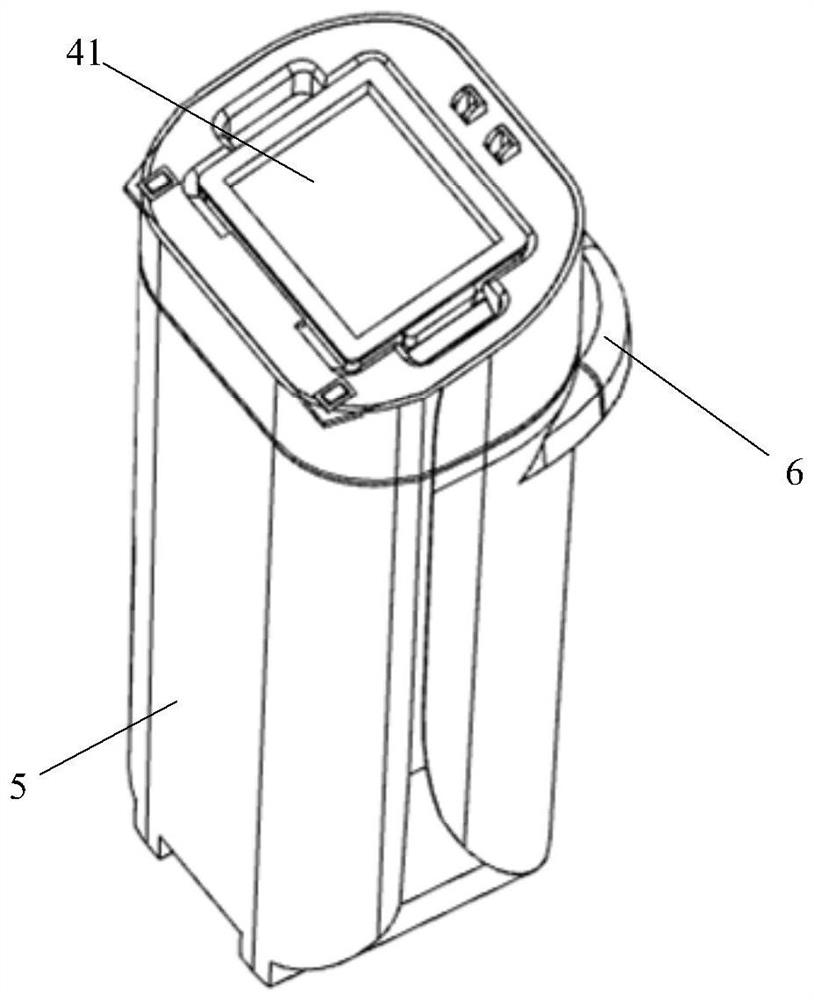

[0067] This embodiment provides a recovery container, such as Figure 1 to Figure 15 ,include:

[0068] The recovery chamber 1 is provided with a fluid inlet 101, in case the dusty fluid enters the recovery chamber 1;

[0069] A filter barrel 2 is used for solid-liquid separation of the dusty fluid entering the recovery cavity 1; the filter barrel 2 is installed in the recovery cavity 1, and the filter barrel 2 is provided with a liquid inlet 201;

[0070] One end of the fluid pipe 3 communicates with the fluid inlet 101 , and the other end communicates with the liquid inlet 201 , so as to introduce the dust-laden fluid into the filter barrel 2 .

[0071] It should be noted that the above-mentioned dusty fluid includes solid debris (such as hair, debris, etc.), waste liquid and dusty airflow, etc., and the cleaning components of the cleaning equipment (such as floor brushes, roller brushes, etc.) are absorbed from the ground into the recovery container All substances are con...

Embodiment 2

[0124] This embodiment provides a cleaning device, including the recycling container provided in Embodiment 1.

[0125] Compared with the prior art, the cleaning equipment provided in this embodiment has the beneficial effect of the recovery container provided in Embodiment 1, and details will not be repeated here.

[0126] The recovery container is detachably installed in the cleaning equipment. Specifically, the cleaning equipment is provided with an assembly cavity suitable for the recovery container, and the recovery container is detachably installed in the assembly cavity through the pressing member 44 .

[0127] The above-mentioned cleaning equipment also includes a cleaning component, which communicates with the fluid inlet 101 of the recovery container, so as to prepare to introduce the dusty fluid absorbed by the cleaning component from the ground to be cleaned into the recovery container.

[0128] The above-mentioned cleaning components include roller brushes, floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com