Heating cigarette fuming section base rod forming device

A molding device and base rod technology, which is applied in the fields of tobacco, tobacco processing, and cigarette manufacturing, can solve the problems of uneven cutting, chaotic processing, and out-of-synchronization of cutting, etc., so as to achieve convenient replacement, ensure stability, and guarantee The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] It should be pointed out that the following detailed description is exemplary and intended to provide further explanation to the present application.

[0072] Note that the working surface of the platform is the upper end surface; the surfaces perpendicular to the upper end surface are the front end surface and the rear end surface respectively; from one end of the upper end surface to the other end, there are slice cutting mechanisms, forming transmission mechanisms, and fixed-length cutting mechanisms; There is a wrap molding mechanism.

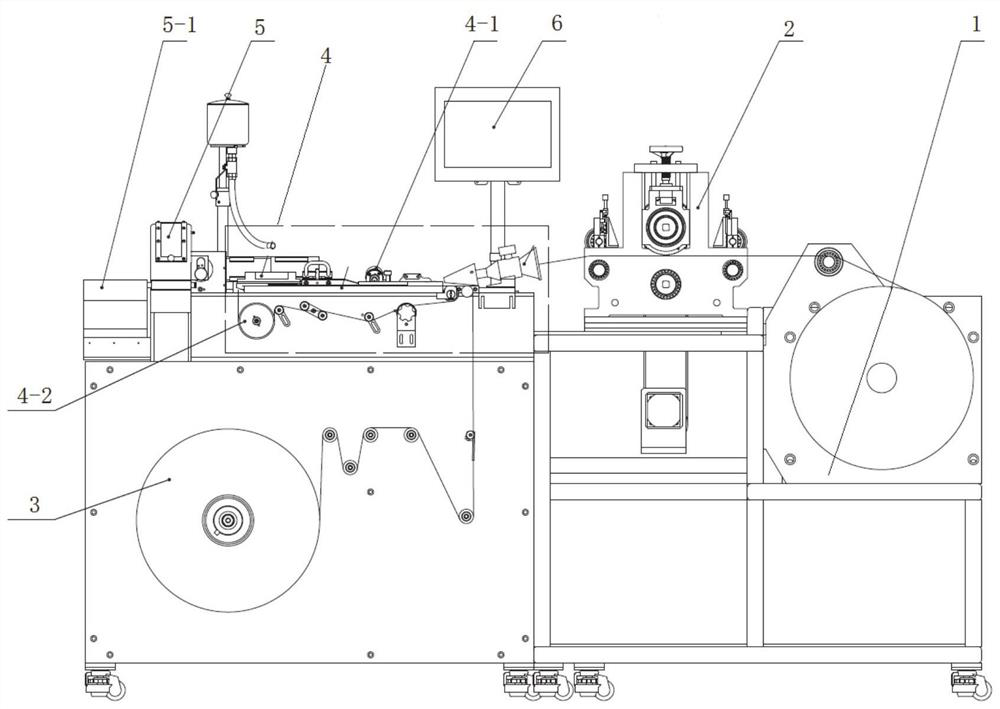

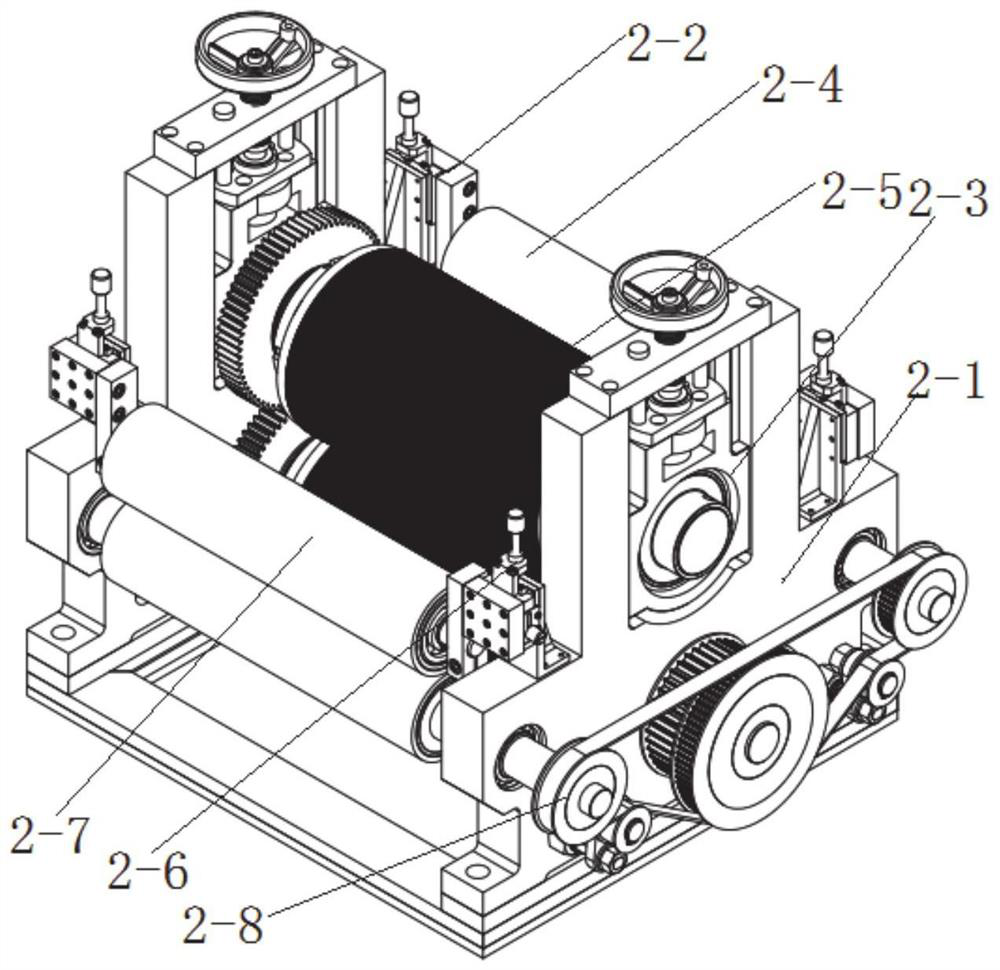

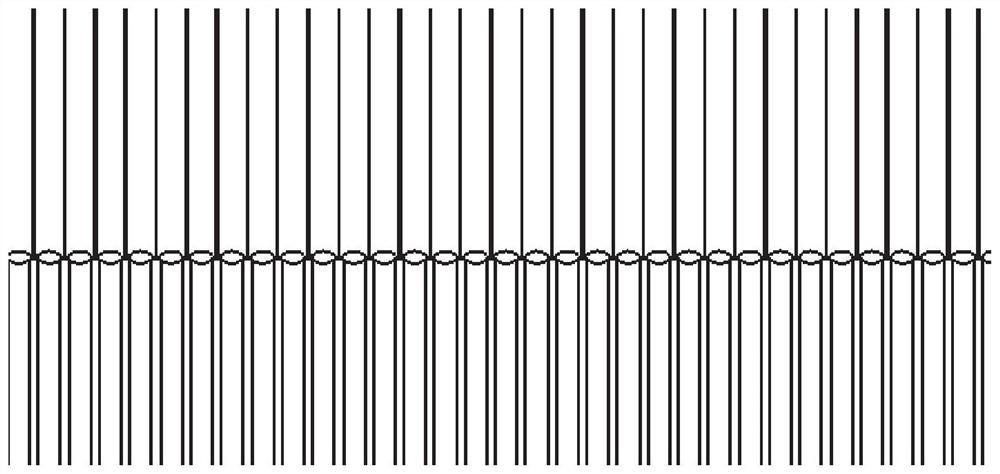

[0073] See how Figure 1-17 , the invention discloses a heating cigarette smoking section base rod forming device, including a platform, a sheet cutting mechanism, a forming transmission mechanism, a wrapping forming mechanism and a fixed-length cutting mechanism; a display is also arranged on the platform; figure 1 As shown, the right side of the front view direction of the view is the right end of the platform, and the left side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com