Detergent supply device for shirt fabric washing and washing process

A supply device and detergent technology, which is applied in the field of fabric washing, can solve the problems of accurate weighing, proportioning and mixing of undisclosed washing liquid, and achieve the effects of avoiding moisture, rapid dispersion, and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

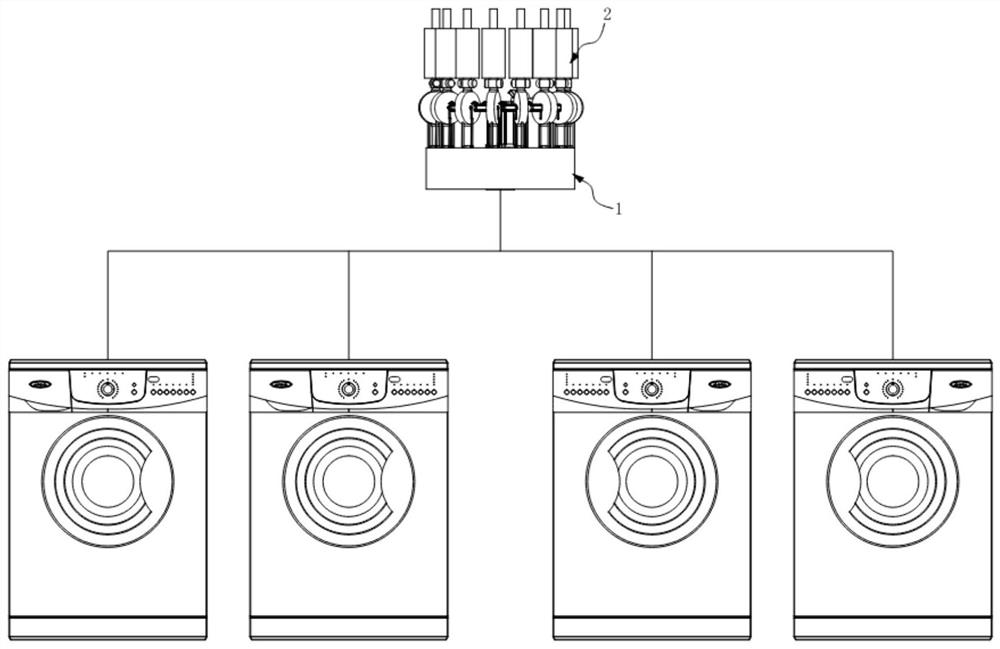

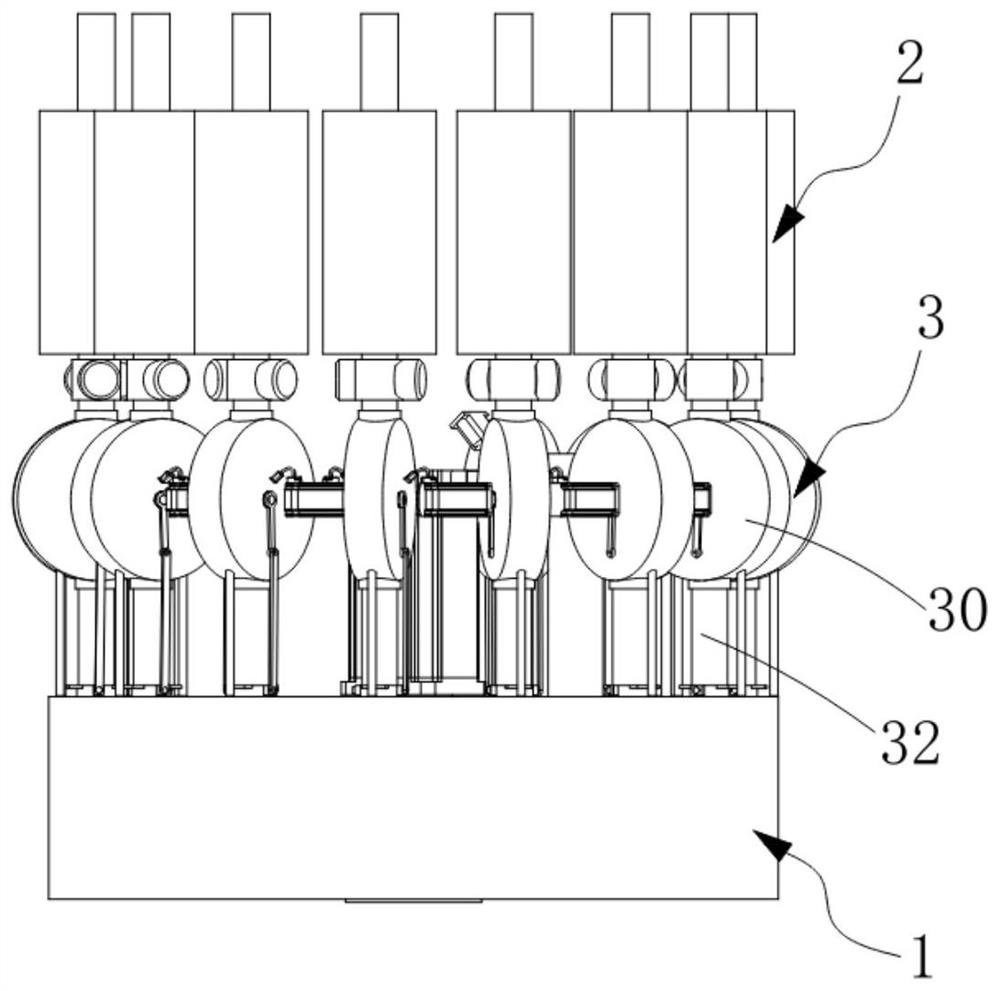

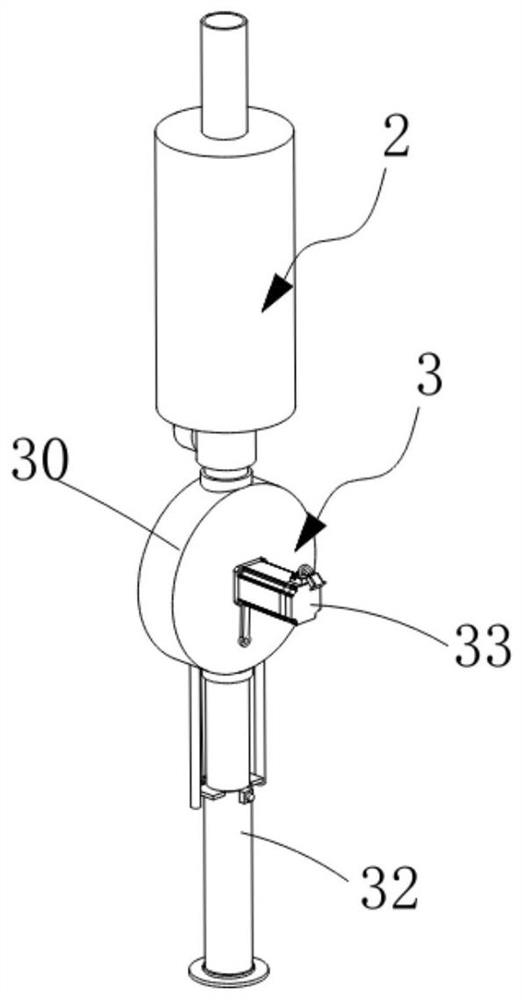

[0055] Such as Figure 1 to Figure 8 As shown, a detergent supply device for washing shirt fabrics includes a mixing bin 1 and several connected raw material bins 2, and also includes:

[0056] Weighing and proportioning mechanism 3, said weighing and proportioning mechanism 3 is evenly arranged on the pipeline that said raw material bin 2 feeds materials to said mixing bin 1, and said weighing and proportioning mechanism 3 includes disc-shaped A weighing bin 30, a weighing assembly 31, a material spraying assembly 32 and a driver 33 are provided. The weighing assembly 31 is rotatably installed in the weighing bin 30, and the weighing assembly 31 carries out the raw materials output from the raw material bin 2. After being weighed, it is poured into the spraying assembly 32, and the spraying assembly 32 is synchronously driven by the drive 33 to spray the weighed raw materials during the drive 33 driving the weighing assembly 31 to rotate and reset. into the deionized water i...

Embodiment 2

[0079] Such as Figure 9 Shown, a kind of shirt fabric washing process comprises the following steps:

[0080] Step 1. Classification. Classify the shirts and select the colored shirts. The colored shirts are shirts that are marked on the washing label and can withstand washing above 30°C. Colored and light-colored clothes that are not easy to fade do not have silk screen or pressed patterns on them;

[0081] Step 2. Check before washing, check whether there are any defects, whether there is damage, dyeing, discoloration, buckle drop, check whether there are rust stains, oil stains, cement stains, mud stains, glue stains and blood stains;

[0082] Step 3, remove stains, remove the stains on the shirt before washing;

[0083] Step 4. Main wash. After scrubbing the neckline and cuffs with a color-friendly detergent, put the shirts into the washing machine in an orderly manner, add water to the middle water level of the washing machine, add detergent for the main wash for 5 minu...

Embodiment 3

[0092] Such as Figure 9 Shown, a kind of shirt fabric washing process comprises the following steps:

[0093] Step 1. Classification. Classify the shirts and select the white shirts. The white shirts are white and light-colored shirts that can withstand washing above 30°C and have no silk screen or pressing patterns and are not easy to fade;

[0094] Step 2. Check before washing, check whether there are any defects, whether there is damage, dyeing, discoloration, buckle drop, check whether there are rust stains, oil stains, cement stains, mud stains, glue stains and blood stains;

[0095] Step 3, remove stains, remove the stains on the shirt before washing;

[0096] Step 4, main wash, put the shirts into the washing machine in an orderly manner, add water to the low water level of the washing machine, add detergent and an appropriate amount of bleaching powder, and main wash for 30 minutes at 40°C to 50°C;

[0097] Step 5. Rinse, after draining, add water to the high water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com