Rapid dense screen winding device for building engineering site construction

A technology for on-site construction and construction engineering, applied in construction, building structure, processing of building materials, etc., can solve the problems of large residual mesh nets, inability to rewind dense mesh nets of different sizes, and inconvenient transfer of dense mesh nets. , to avoid wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

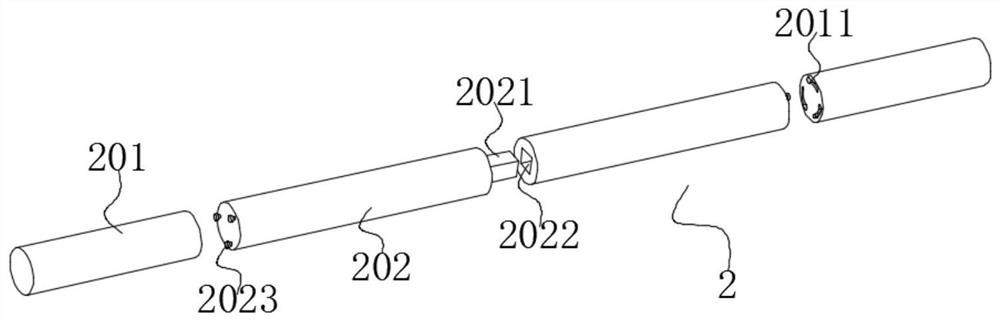

[0078] see image 3 As shown, the positioning assembly for single-layer dense mesh positioning includes a first rectangular column 2021 and a first rectangular blind groove 2022, and the first rectangular column 2021 is arranged in the middle of the end face of one of the winding columns 202, while the first rectangular blind slot The slot 2022 is arranged in the middle of the end face of the other winding post 202 , and the first rectangular post 2021 is clearance-fitted in the first rectangular blind slot 2022 . This setting facilitates the linkage of the two winding columns 202;

[0079] When this arrangement is in use, a part of one end of the dense mesh is pressed against one end of the first rectangular column 2021, and when the two winding columns 202 move closer to each other, the first rectangular column 2021 drives the part of the dense mesh into the first rectangular column. In the blind groove 2022, one end of the dense mesh is fixed. At this time, the winding col...

Embodiment 2

[0081] see Figure 5-7 As shown, the positioning assembly for multi-layer dense mesh positioning includes a linkage column 2024 and a folding rod 2025. The linkage column 2024 is arranged in the middle of the end face of one of the winding columns 202, and the free end of the linkage column 2024 is provided with a second Rectangular column 2027, the middle part of the end face of the other winding column 202 is provided with a second rectangular blind groove 2026 for clearance fit with the second rectangular column 2027, which facilitates the linkage of the two winding columns 202;

[0082] A plurality of folding rods 2025 are arrayed along the same radial direction on the relatively close end faces of the two winding columns 202;

[0083] The multiple folding rods 2025 on the two winding columns 202 are intersected, and at least one of the multiple folding rods 2025 on the same winding column 202 is tangent to the winding column 202. This setting can realize winding The subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com