Automatic film removing machine

A film machine, automatic technology, applied in the direction of conveyors, conveyor objects, rigid containers, etc., can solve problems such as influence, take away or dump, and difficult bottle circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

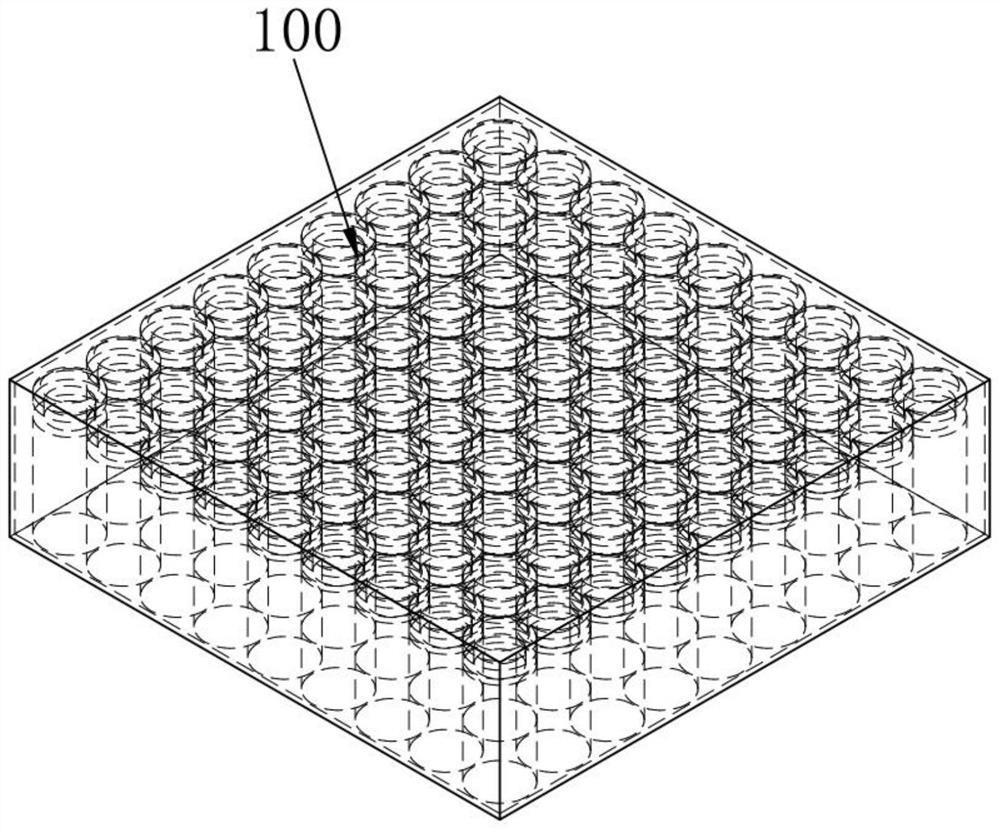

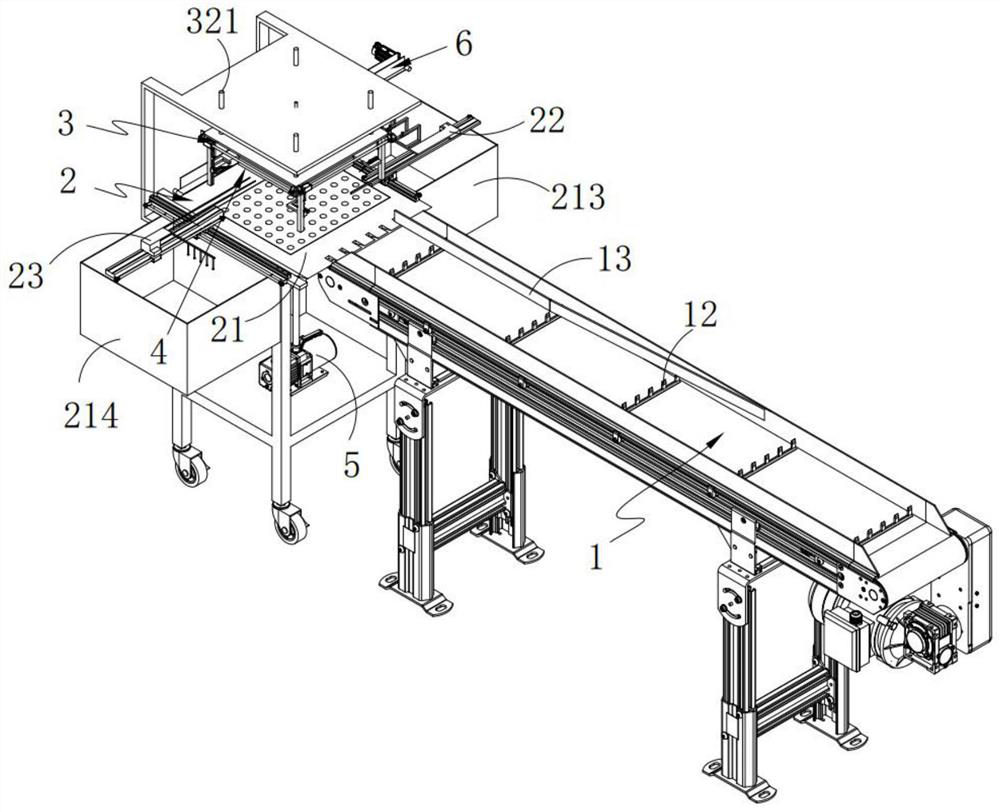

[0054] Such as image 3 Shown, a kind of automatic film removing machine comprises:

[0055] Feeding unit 1, said feeding unit 1 is responsible for conveying the whole box of material 100 containing the bottle to the bottom of the film cutting unit 3;

[0056] positioning unit 2, such as Figure 4-10 As shown, the positioning unit 2 is arranged at the tail end of the feeding unit 1, and it includes a positioning frame 21, a left positioning assembly 22 and a right positioning assembly 23 respectively arranged on the left and right sides of the positioning frame 21; the left positioning assembly 22 includes a left positioning slide 221 that is slidably arranged on one side of the positioning frame 21, and a left positioning piece 222 that is slidably provided on the top of the left positioning slide 221; The right positioning slide plate 231, slide the right positioning part 232 that is located on the right positioning slide plate 231 top;

[0057] Cutting film unit 3, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com