Molding sand mixing device used in wear-resistant steel casting

A wear-resistant steel and molding sand technology, which is used in foundry molding equipment, machinery for cleaning/processing mold materials, and manufacturing tools, etc., can solve the problems of poor mixing uniformity and low mixing efficiency of molding sand, and ensure clean and convenient. performance, improve sand mixing efficiency, and ingenious and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

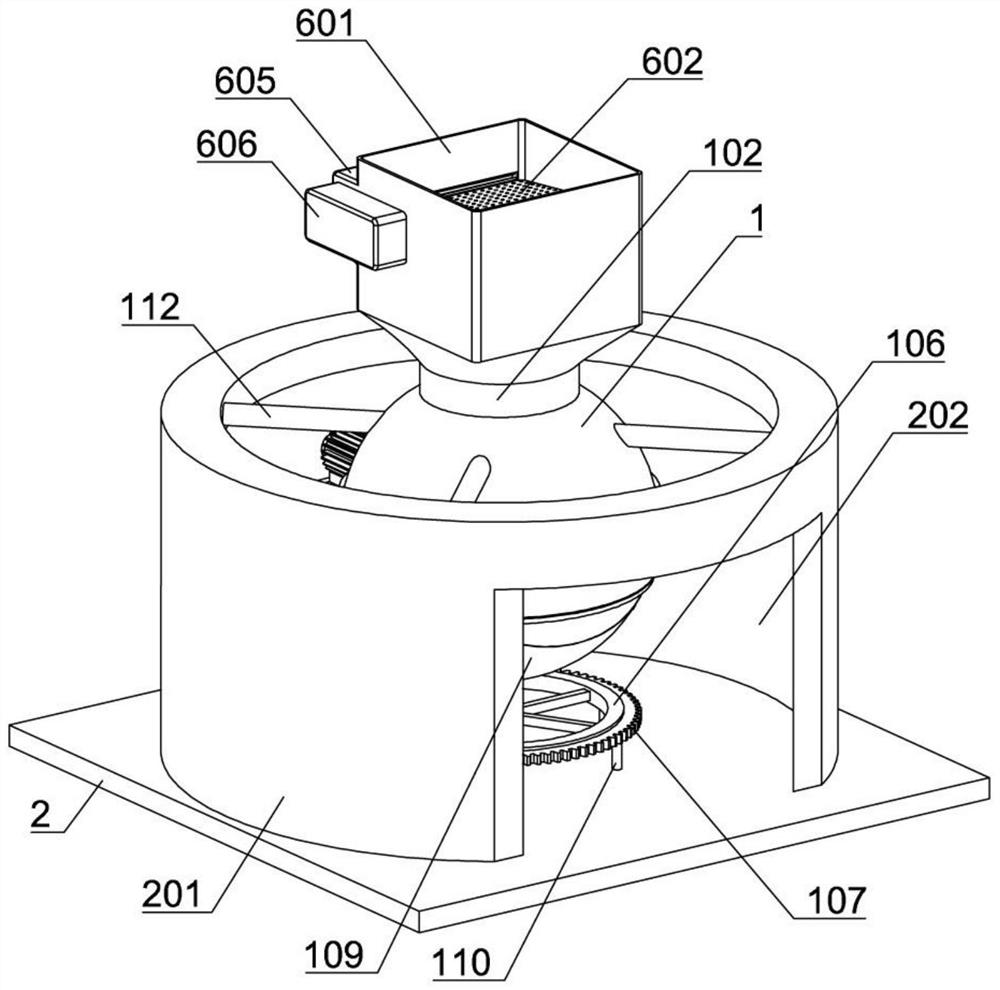

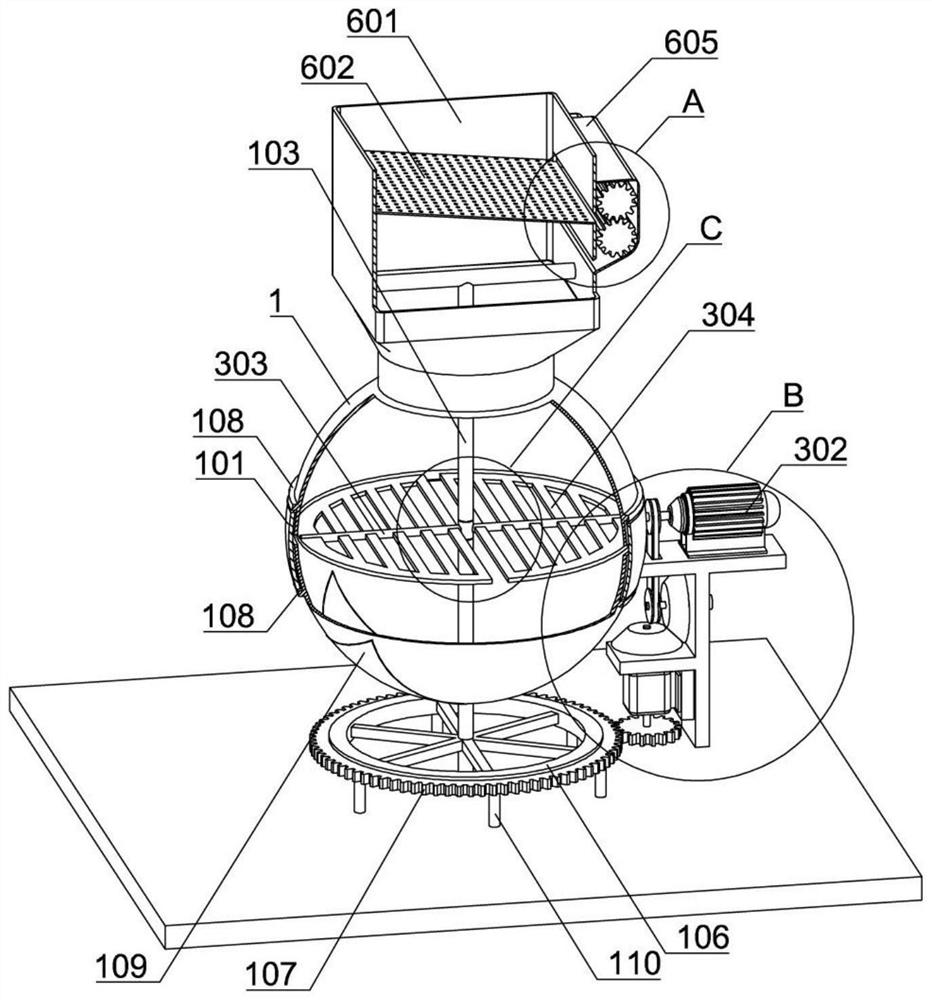

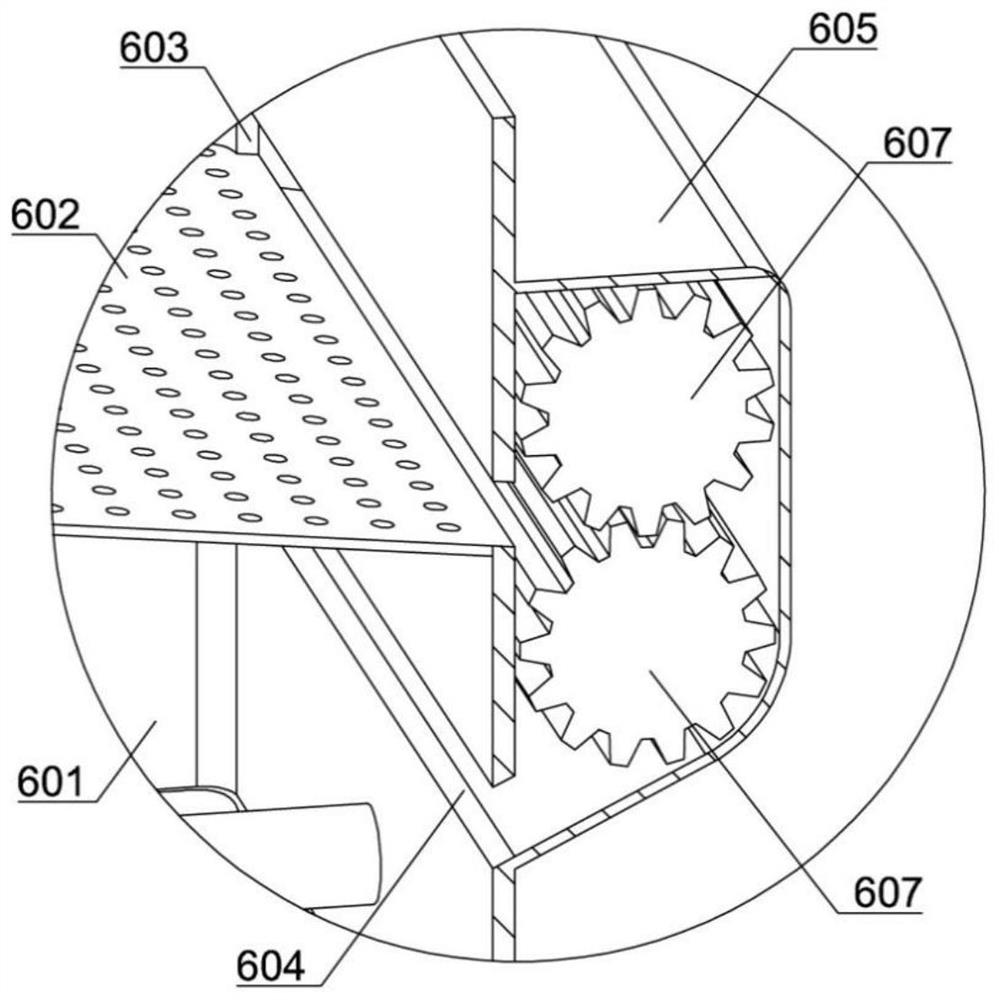

[0037] Such as Figure 1-8 As shown, the present invention is a molding sand mixing device used in wear-resistant steel casting, including a spherical stirring tank 1, a feeding mechanism, a stirring mechanism, a base 2 and a control system, and the upper end surface of the base 2 is fixed with an annular Support 201, the spherical stirring tank 1 is fixed on the inner upper end of the annular support 201, the feeding mechanism is fixedly connected with the feed channel 102 above the spherical stirring tank 1, and the outer peripheral side of the spherical stirring tank 1 An annular plate 101 is installed for horizontal rotation, and a connecting rod 103 passing through the center of the ball is vertically fixed in the spherical stirring tank 1, and the lower end of the connecting rod 103 runs through the bottom of the spherical stirring tank 1 and is fixed on the base 2, so The upper end of the connecting rod 103 runs through the feed channel 102 and is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com