Glue point three-dimensional reconstruction method based on uncalibrated photometric stereoscopic vision

A photometric three-dimensional, glue point technology, applied in the field of three-dimensional measurement, can solve the problems of low efficiency, complex light source calibration, environmental restrictions and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

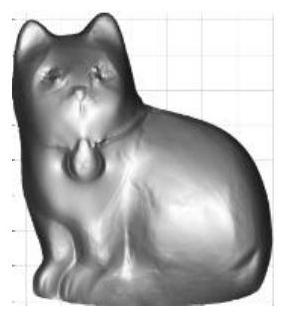

[0080] This method is experimented on real objects to achieve the purpose of three-dimensional reconstruction.

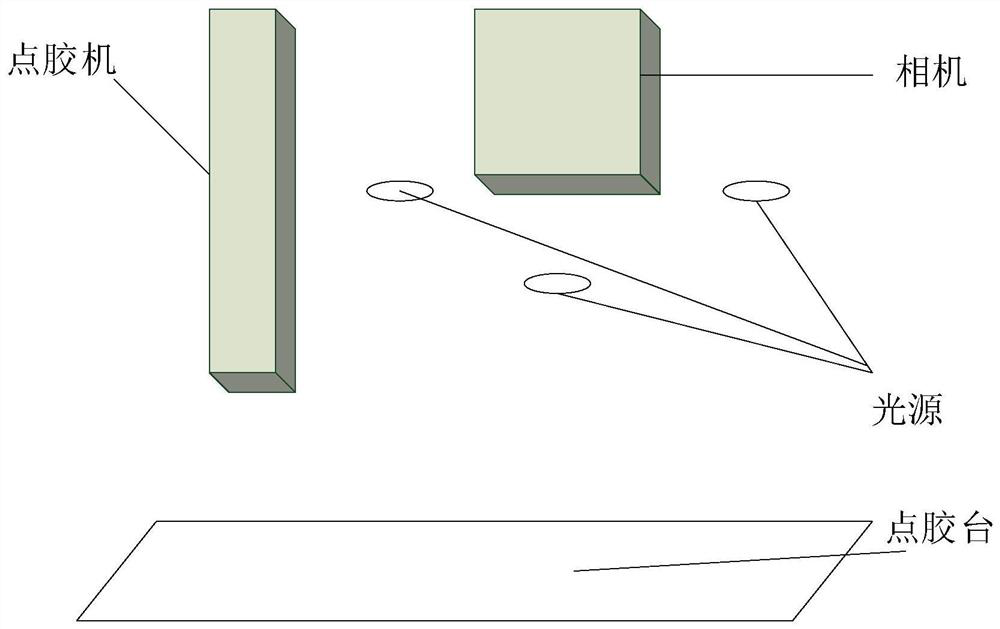

[0081] Step 1, obtain object pictures under multiple light sources, such as Figure three One of these is shown. The image source is DiLiGenT database.

[0082] Step 2, preprocess the image set and perform batch separation, and separate it into specular reflection image set I 1 and Diffuse Image Set I 2 . Figure 4 and Figure 5 respectively Figure 1 Separated diffuse and specular reflection images.

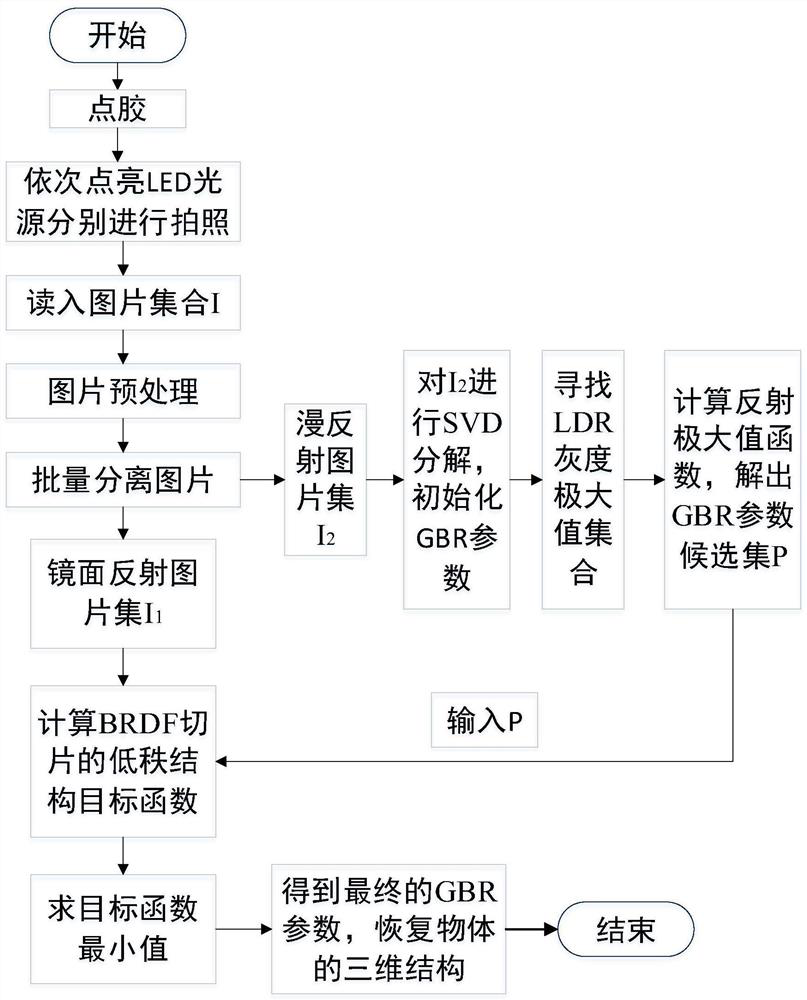

[0083] Step three, for I 2 Perform SVD decomposition to initialize GBR parameters, find the LDR gray maximum value set, and calculate the reflection maximum value function to solve the candidate set P of GBR parameters μ, ν, λ. then to I 1 Calculate the low-rank structure of BRDF slices and solve the minimum value of the objective function. The obtained parameter values of μ, ν, and λ are the parameter values of the final GBR transformation matrix, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com