System and process for testing tolerance performance of photovoltaic module

A technology for photovoltaic modules and test systems, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve problems such as simple functions, poor detection results, and inability to simulate photovoltaic modules, so as to reduce workload and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

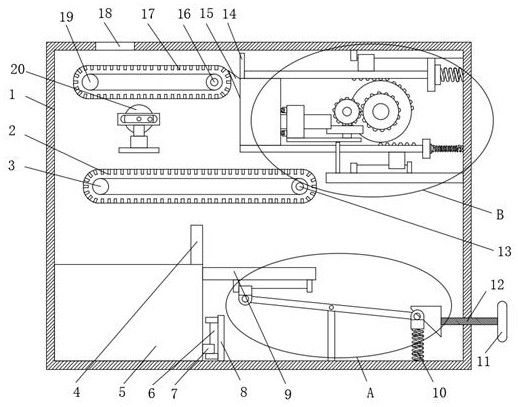

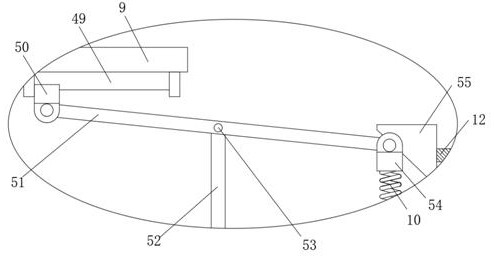

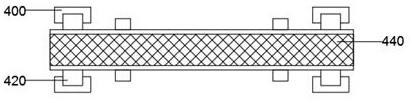

[0045] Example 1: as Figure 1-14 As shown, a test system for the endurance performance of photovoltaic modules includes a test box 1, a fixed box 24 is fixedly connected to the inner walls of the two sides of the test box 1, and a vibration box 25 is slidably connected to one side of the fixed box 24. A triangular block 15 is fixedly connected on one side, a fourth fixing plate 43 is fixedly connected on one side of the inner wall of the test box 1, and a lower baffle 46 is slidably connected to the top of the fourth fixing plate 43, and the inside of the lower baffle 46 is provided with a discharge Port 67, the top inner wall of the test box 1 is slidably connected with the upper baffle 29, one end of the upper baffle 29 is fixedly connected with the second baffle 14, the lower surface of the upper baffle 29 and the upper surface of the lower baffle 46 are respectively connected with the vibration. The top and bottom of the box 25 are in conflict, the inner wall of one side ...

Embodiment 2

[0061] Example 2: as Figure 15 As shown, a test system for the resistance performance of photovoltaic modules, the difference between this embodiment and the first embodiment is that a transparent glass window 78 is provided on one side of the test box 1, and a box door 81 is hinged on one side of the test box 1, A door handle 68 is fixedly connected to one side of the box door 81 , and it is convenient to observe the test situation through the transparent glass window 78 .

[0062] Working principle: put the photovoltaic module into the test box 1 through the feeding port 18, start the motor 79, the output shaft of the motor 79 drives the fourth rotating rod 32 to rotate, the fourth rotating rod 32 drives one of the synchronous wheels 61 to rotate, and the synchronous wheel 61 rotates. The synchronous belt 62 is driven to rotate, the synchronous belt 62 drives the second rotating rod 16, the fifth rotating rod 73 and the first rotating rod 13 to rotate, the second rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com