Low-temperature defrosting water pan and drainage pipeline and use method thereof

A technology for drainage pipes and water receiving trays, which is applied in the fields of drainage pipes and low-temperature defrosting water receiving trays, can solve the problems of easy blockage of the water receiving trays, low service life and high electric power, etc. The effect of electric power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

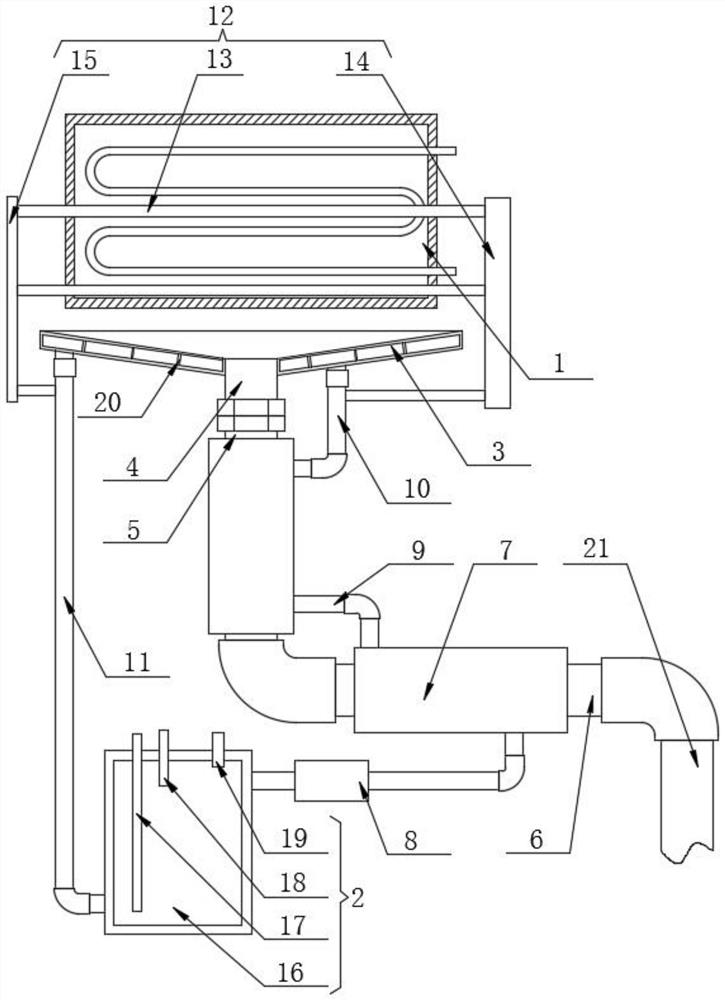

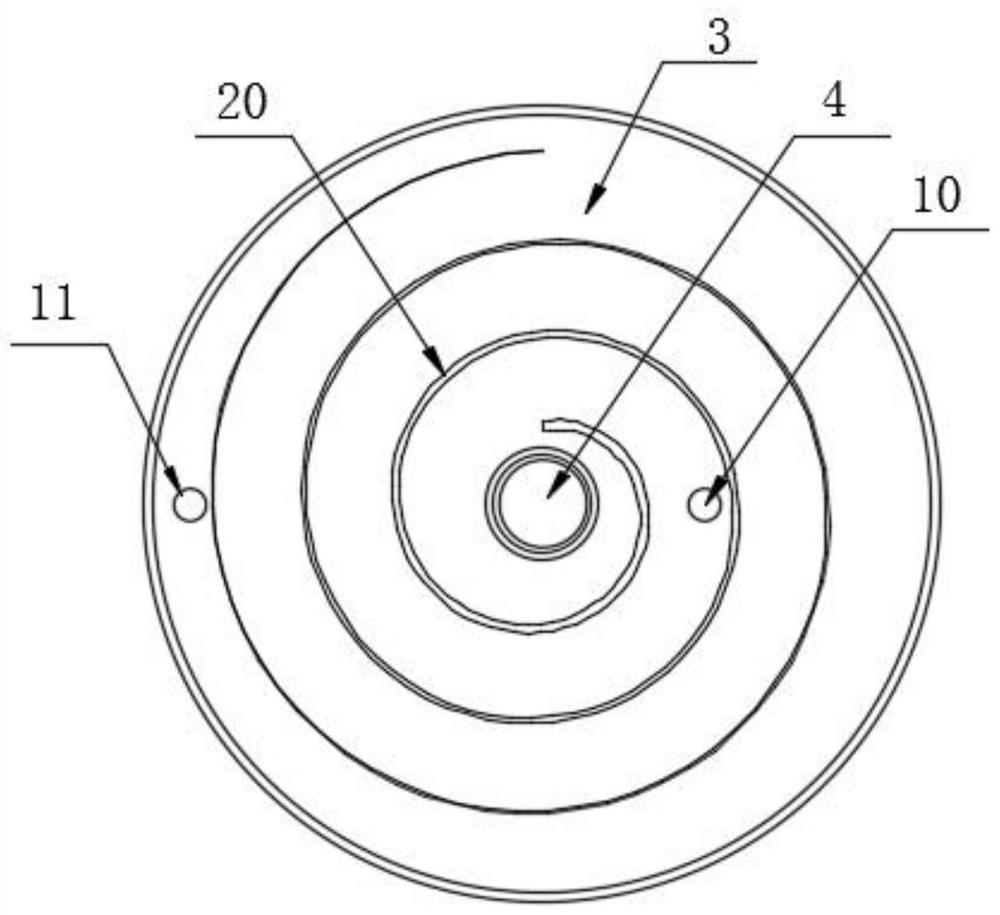

[0046] A low-temperature defrosting water tray and drain pipe, as attached figure 1 As shown, it includes an evaporator 1 , a heating assembly 2 arranged outside the refrigerator, and a water receiving tray 3 arranged below the evaporator 1 .

[0047] As a preferred solution, the bottom of the water receiving tray 3 is connected with a water outlet pipe 4, and the bottom end of the water outlet pipe 4 is connected with a first water guide pipe 5, and the bottom end of the first water guide pipe 5 is connected with a second water guide pipe 6 through a connector. The outside of the first water pipe 5 and the second water pipe 6 are sheathed and slidably connected with an outer pipe 7. The output end of the heating assembly 2 communicates with the inside of an outer pipe 7 through a circulating pump 8, and the space between the two outer pipes 7 is It communicates with the connection pipe 9, and one end of the other outer pipe 7 communicates with the inside of the water receivin...

Embodiment 2

[0049] This embodiment is an improvement of the previous embodiment, a low-temperature defrosting water tray and drainage pipe, as attached figure 1 As shown, it includes an evaporator 1 , a heating assembly 2 arranged outside the refrigerator, and a water receiving tray 3 arranged below the evaporator 1 .

[0050] As a preferred solution, the bottom of the water receiving tray 3 is connected with a water outlet pipe 4, and the bottom end of the water outlet pipe 4 is connected with a first water guide pipe 5, and the bottom end of the first water guide pipe 5 is connected with a second water guide pipe 6 through a connector. The outside of the first water pipe 5 and the second water pipe 6 are sheathed and slidably connected with an outer pipe 7. The output end of the heating assembly 2 communicates with the inside of an outer pipe 7 through a circulating pump 8, and the space between the two outer pipes 7 is It communicates with the connection pipe 9, and one end of the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com