Mechanical gear cleaning device and operation method thereof

A technology for cleaning devices and gears, applied in cleaning methods and appliances, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as difficult stain cleaning, insufficient cleaning, and a lot of time-consuming, so as to avoid insufficient Thoroughness, improving convenience, and improving the effect of cleaning diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

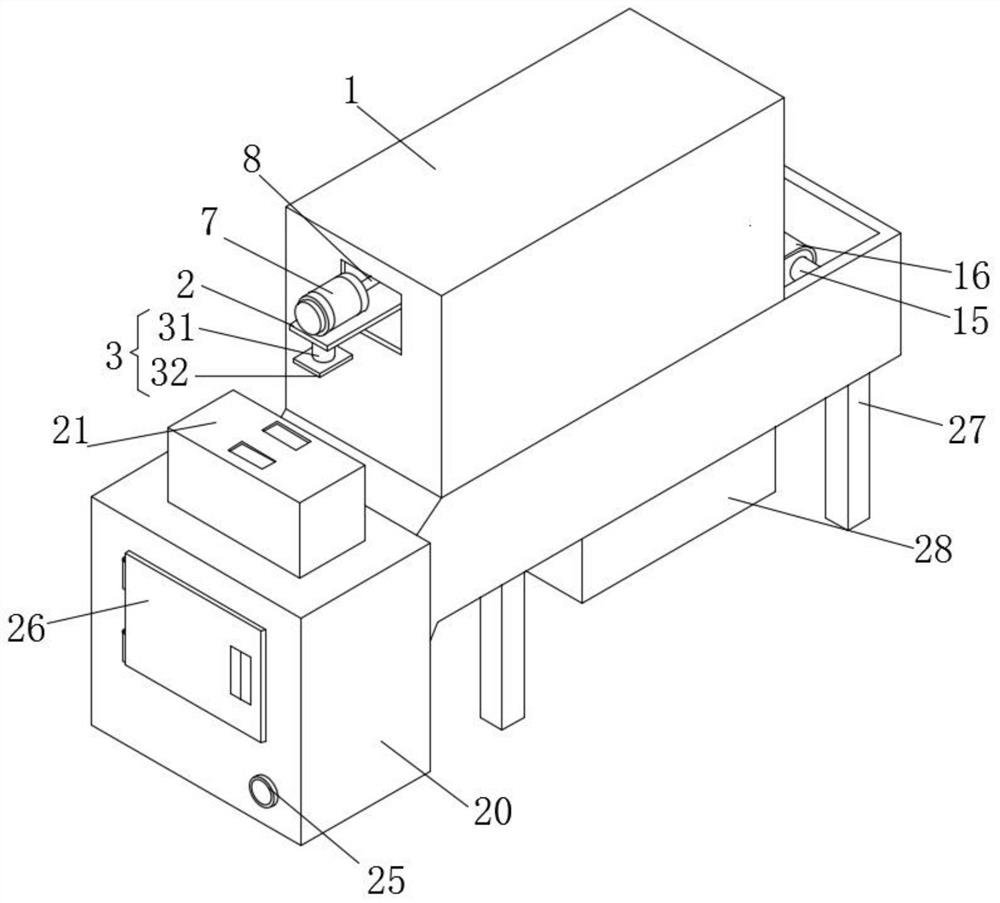

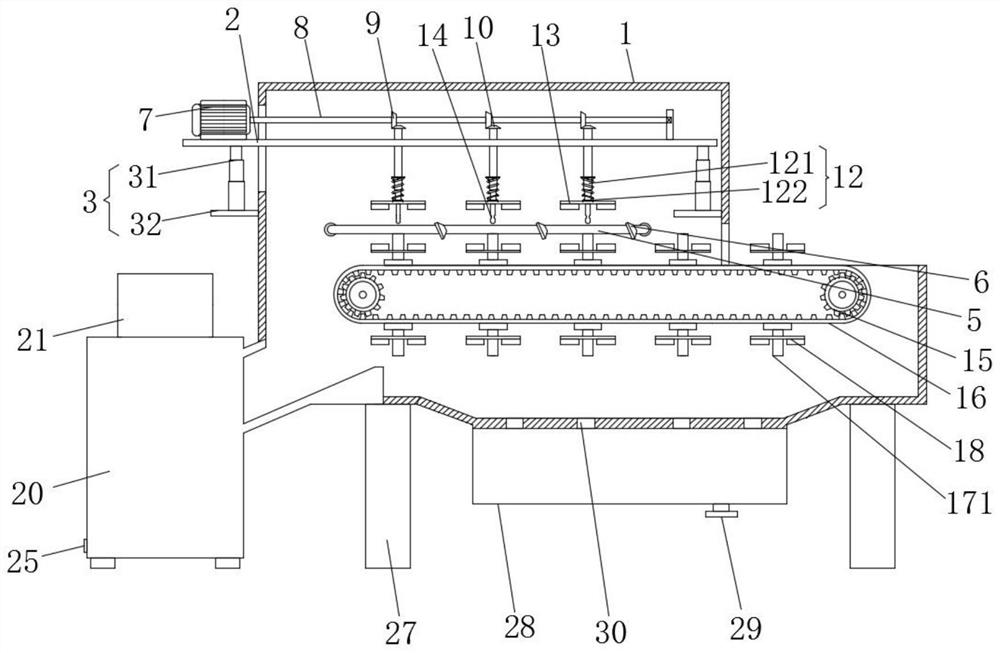

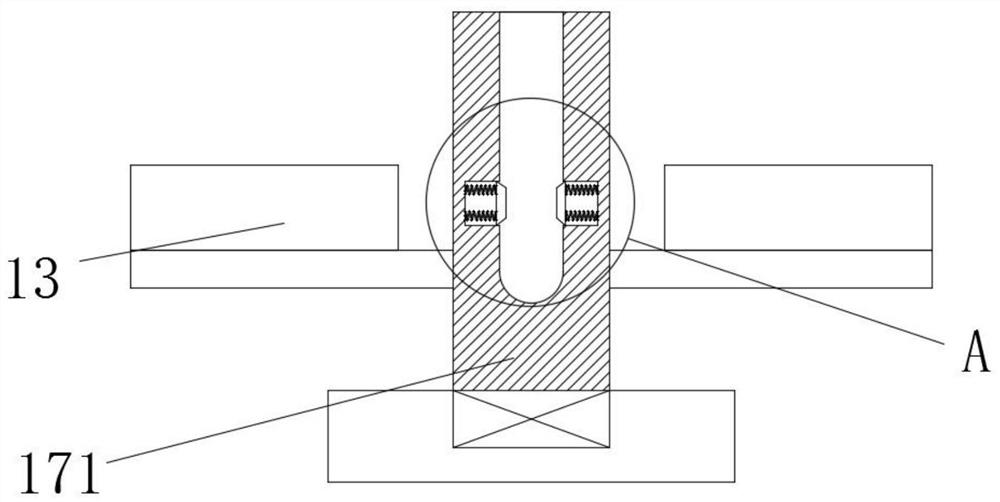

[0037] Such as Figure 1-7As shown, the present invention provides a technical solution: a mechanical gear cleaning device, including a cleaning box 1, one side of the cleaning box 1 is slidingly connected with a lifting plate 2, and both sides of the bottom of the lifting plate 2 are bolted with a lifting mechanism 3 The vertical movement of the lifting plate 2 is driven by the lifting mechanism 3, which effectively improves the role of the device to fix the gears to be cleaned. A flushing mechanism 4 is installed on the back of the cleaning box 1, and one end of the flushing mechanism 4 is connected to a water outlet pipe 5. And the front of the water outlet pipe 5 is connected with a nozzle 6, and the gear to be cleaned is washed by the flushing mechanism 4, which effectively improves the multi-directional cleaning effect of the device to be cleaned. The top of the lifting plate 2 is bolted with a first motor 7, and The output end of the first motor 7 is bolted with a rotat...

Embodiment 2

[0039] Such as Figure 1-7 As shown, the present invention provides a technical solution: a mechanical gear cleaning device, including a cleaning box 1, one side of the cleaning box 1 is slidingly connected with a lifting plate 2, and both sides of the bottom of the lifting plate 2 are bolted with a lifting mechanism 3 The vertical movement of the lifting plate 2 is driven by the lifting mechanism 3, which effectively improves the role of the device to fix the gears to be cleaned. A flushing mechanism 4 is installed on the back of the cleaning box 1, and one end of the flushing mechanism 4 is connected to a water outlet pipe 5. And the front of the water outlet pipe 5 is connected with a nozzle 6, and the gear to be cleaned is washed by the flushing mechanism 4, which effectively improves the multi-directional cleaning effect of the device to be cleaned. The top of the lifting plate 2 is bolted with a first motor 7, and The output end of the first motor 7 is bolted with a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com