Battery cell connecting assembly, lithium battery and assembling method

A technology for connecting components and lithium batteries, which is applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, and electrolyte batteries. Convenient fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

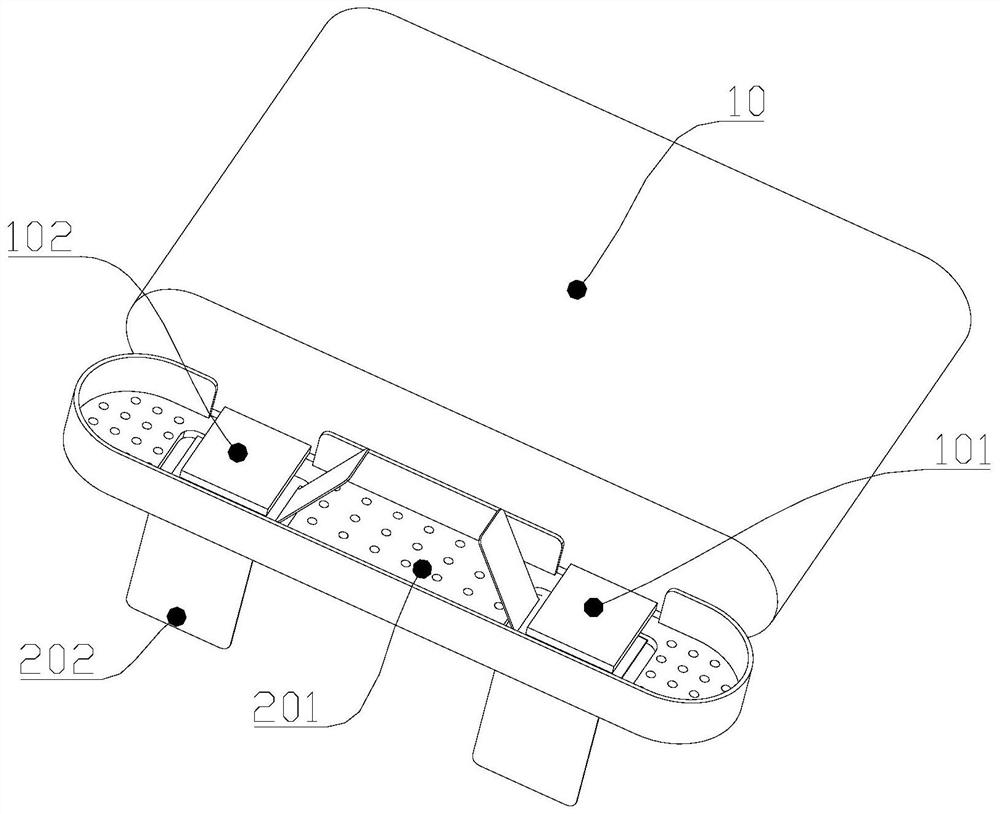

[0051] refer to figure 1 , this embodiment provides a battery connection assembly, including an end cap 201 that can be fastened to one end of at least one battery cell 10, combined with figure 2 , the end of the battery cell 10 covered by the end cap 201 has a positive tab 101 and a negative tab 102, two pole pieces 202 are arranged on the outside of the end cover 201, and the pole pieces 202 are connected to the inner side of the end cap 201 The bottom sheet 2021 , the bottom sheet 2021 can be welded and fixed with the positive tab 101 or the negative tab 102 .

[0052] In this embodiment, the bottom piece 2021 and the pole piece 202 are connected together to facilitate fixing with the tabs of the battery cell 10. The pole piece 202 and the bottom piece 2021 are directly fixed on the connection assembly, and the entire connection assembly can be directly operated during assembly. There is no need to frequently pick up separately set pole pieces and connecting pieces, reduc...

Embodiment 2

[0060] In this embodiment, the structure of the lithium battery is introduced by taking the cooperation between the connection assembly 20 and the two battery cells 10 as an example. Figure 9 , when connecting multiple cells 10, the positive tabs 101 and negative tabs 102 on the multiple cells 10 are arranged in the same plane. In this embodiment, the multiple cells 10 are arranged along the length direction, and the end cap 201 The width remains the same, and the length needs to be extended to accommodate two battery cells 10 . Finally, the structure of the terminal cover 201 is roughly the same as the end surface of the battery cells 10 after arrangement. On the end cover 201, a pole piece hole 205 is respectively set at the position of each pole piece, and a bottom piece 2021 is respectively fixed in each pole piece hole 205, and the positive pole lug 101 and the negative pole lug 102 of the adjacent battery cell 10 are arranged at intervals ;

[0061] combine Figure 10...

Embodiment 3

[0064] This embodiment also provides a lithium battery based on the connection assembly provided in the above embodiment, refer to Figure 12 , including a cover plate assembly 70, a housing 80, a connecting assembly 20 and an electric core 10, one end of the housing 80 is open, and at least two connecting assemblies 20 matched with at least one electric core 10 can be placed in a regular arrangement in the shell Inside the body 80, the cover plate assembly 70 includes a cover plate 701 matching the opening of the housing 80 and two poles 702 arranged on the outer surface of the cover plate 701, the poles 702 can pass through the cover plate 701 and the Homopolar pole pieces 202 of at least two connection assemblies 20 are connected respectively.

[0065] In this embodiment, the positive tab 101 and the negative tab 102 of at least one battery cell 10 are connected in parallel through the connection assembly 20 to form positive and negative tabs 202. For the influence of fewe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com