Two-stage metal hard sealing ball valve

A technology of hard sealing and sealing valves, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of wear and tear of opening and closing parts and affect service life, and achieve the effect of avoiding reciprocating rotation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

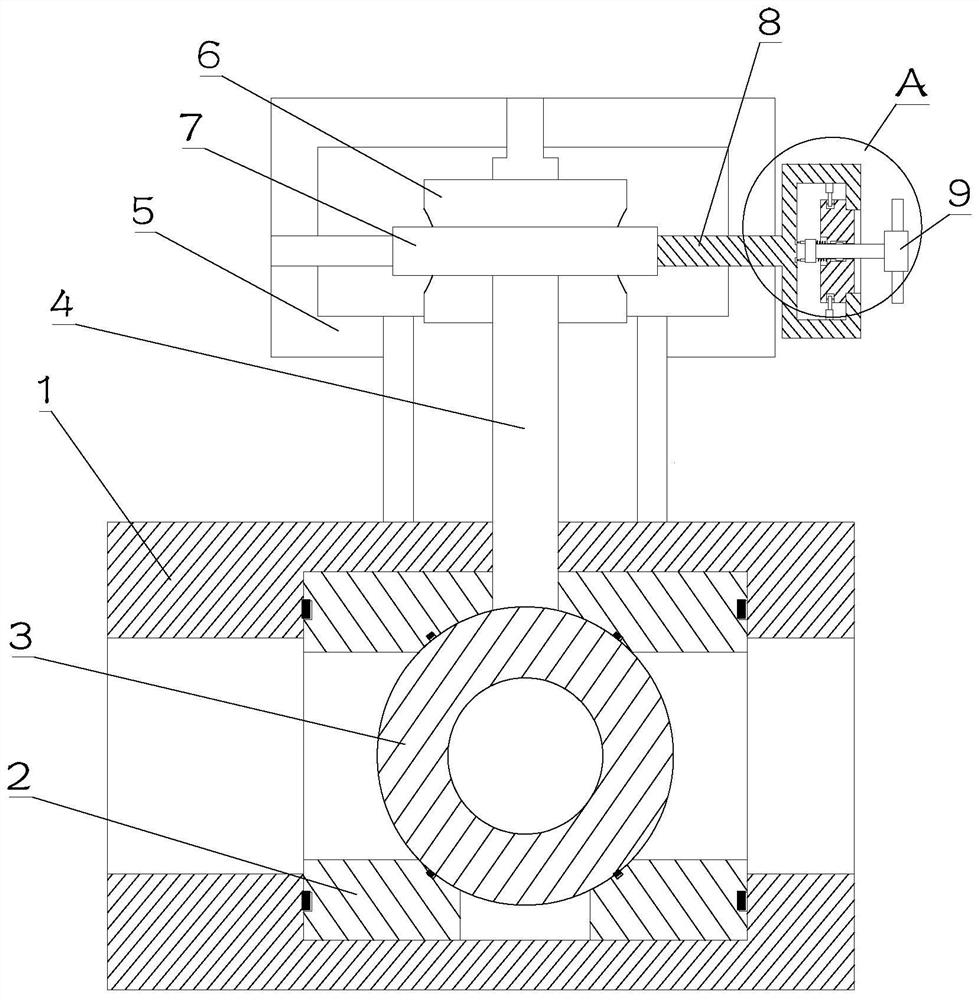

[0026] see figure 1 , in Embodiment 1 of the present invention, it is a structural diagram of a two-stage metal hard-sealed ball valve provided by the embodiment of the present invention, including: a valve body 1, a ball 3 and a driving component;

[0027] The ball 3 is arranged inside the valve body 1, and is used to control the on-off of the valve body 1;

[0028] The driving part is arranged on the valve body 1 and is used to drive the ball 3 to rotate in one direction, and the ball 3 can adjust the opening during the rotation.

[0029] Specifically, the sphere 3 is driven to rotate in one direction through the driving component, so that the sphere 3 can rotate in one direction during the switching process, so that the entire sealing surface of the sphere 3 can be in contact with the sealing part inside the valve body 1 during the rotation process, Further avoiding the reciprocating rotation of the sphere 3 during use in the prior art, so that only part of the sealing sur...

Embodiment 2

[0031] see figure 1 The main difference between this embodiment 2 and embodiment 1 is that a sealing valve seat 2 is provided inside the valve body 1, and the ball 3 is rotatably arranged inside the sealing valve seat 2; both ends of the sealing valve seat 2 are sealed by metal The gasket is installed in the installation groove on the valve body 1, and the sealing valve seat 2 is provided for installing the ball 3.

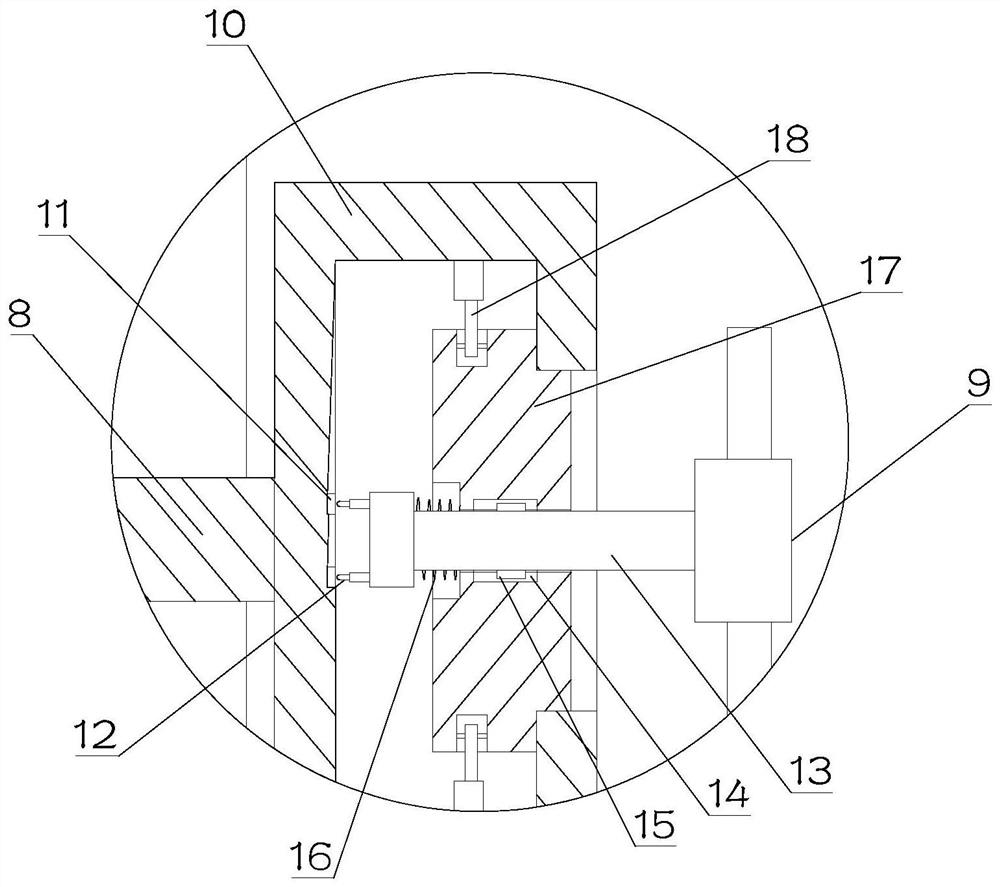

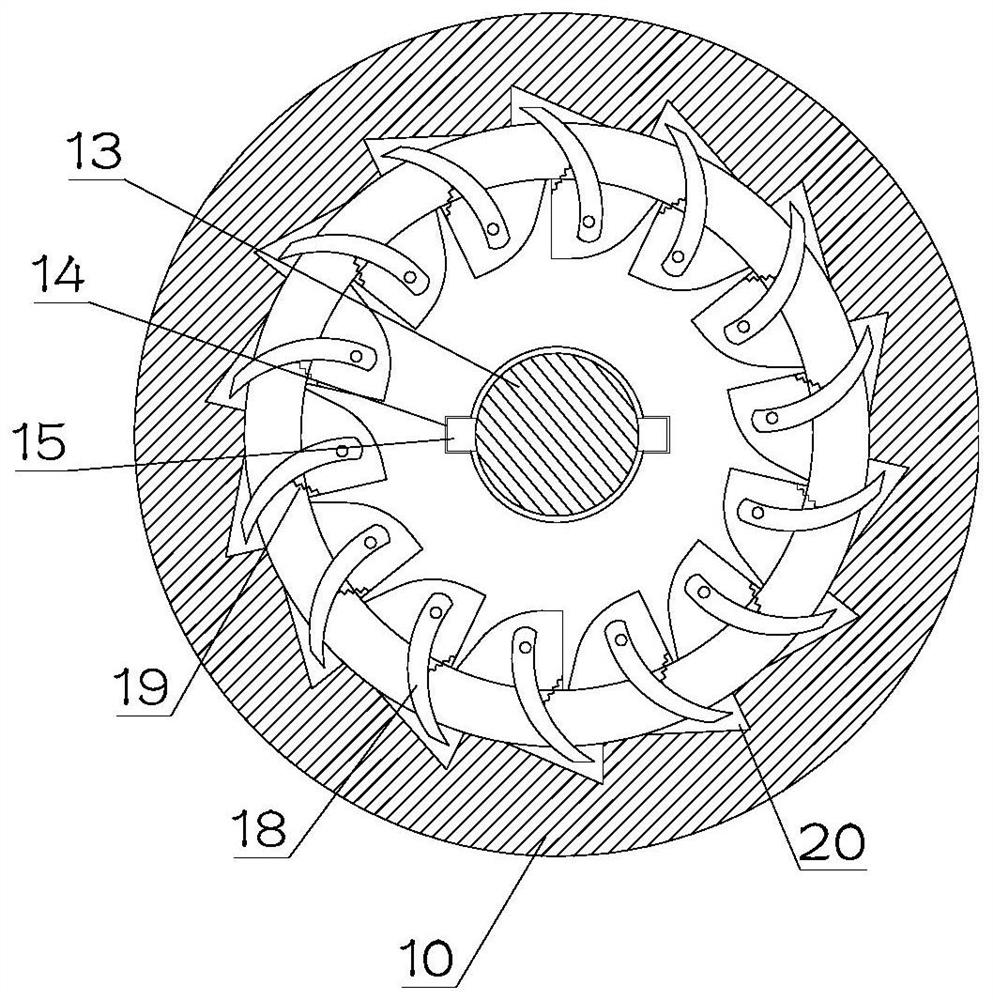

[0032] see Figure 2-3 , as a preferred embodiment of the present invention, the ball 3 is provided with a valve stem 4, in order to realize the one-way transmission of the driving ball 3, so the driving part includes a transmission assembly and a one-way part, and the transmission part and the valve The rod 4 is connected in transmission, and the transmission part is connected with the one-way part.

[0033] As a preferred embodiment of the present invention, the transmission part can be connected with the valve stem 4 through a gear, or can be connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com