Method for regulating and controlling thermal response temperature of ionic liquid gel, thermal response ionic liquid gel and application thereof

An ionic liquid and thermal response technology, applied in the field of responsive materials, can solve problems such as insufficient mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

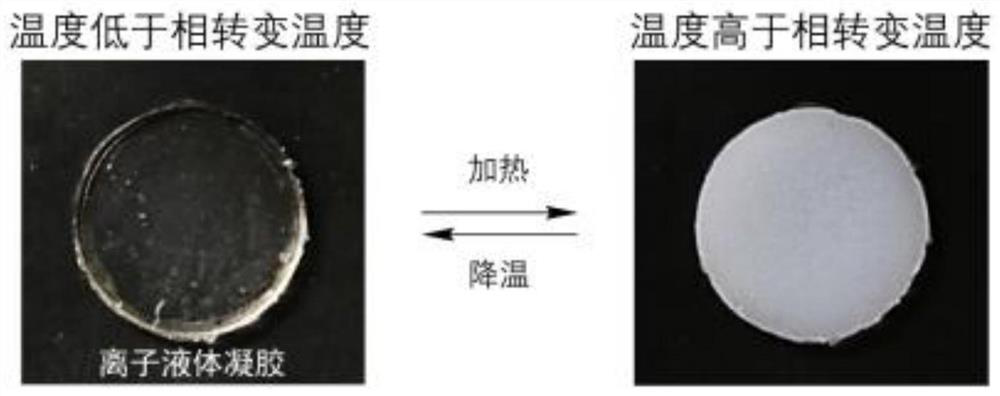

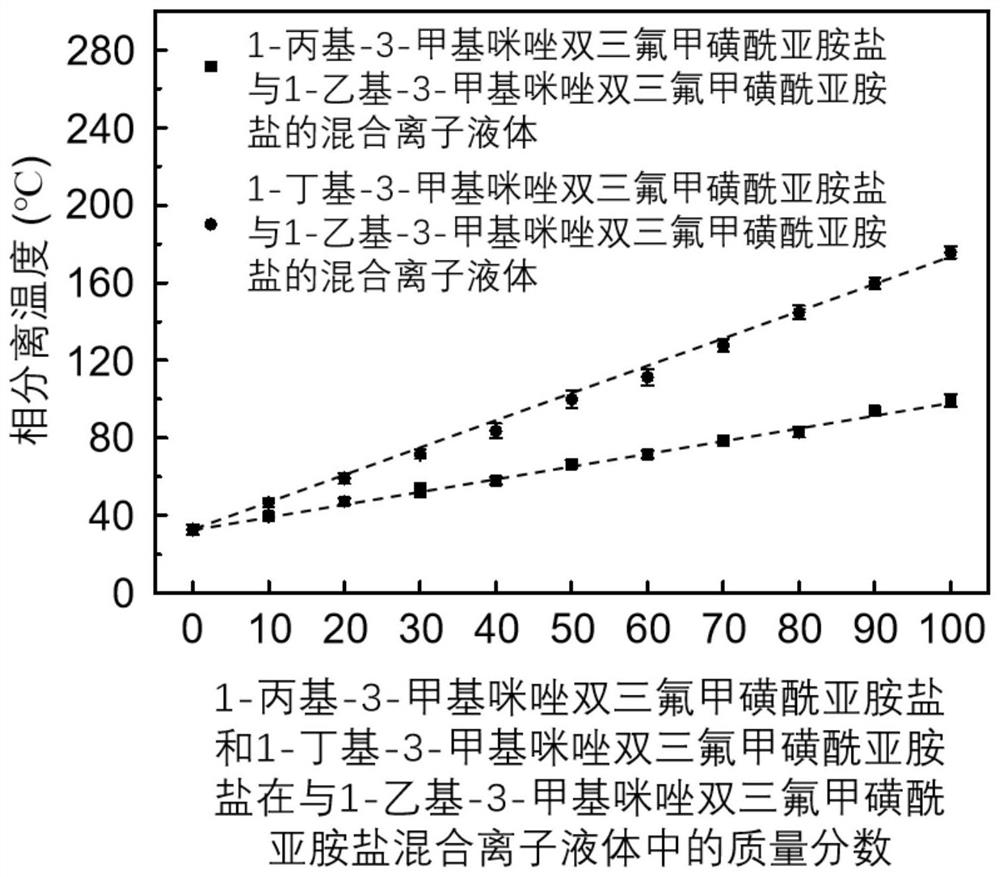

Method used

Image

Examples

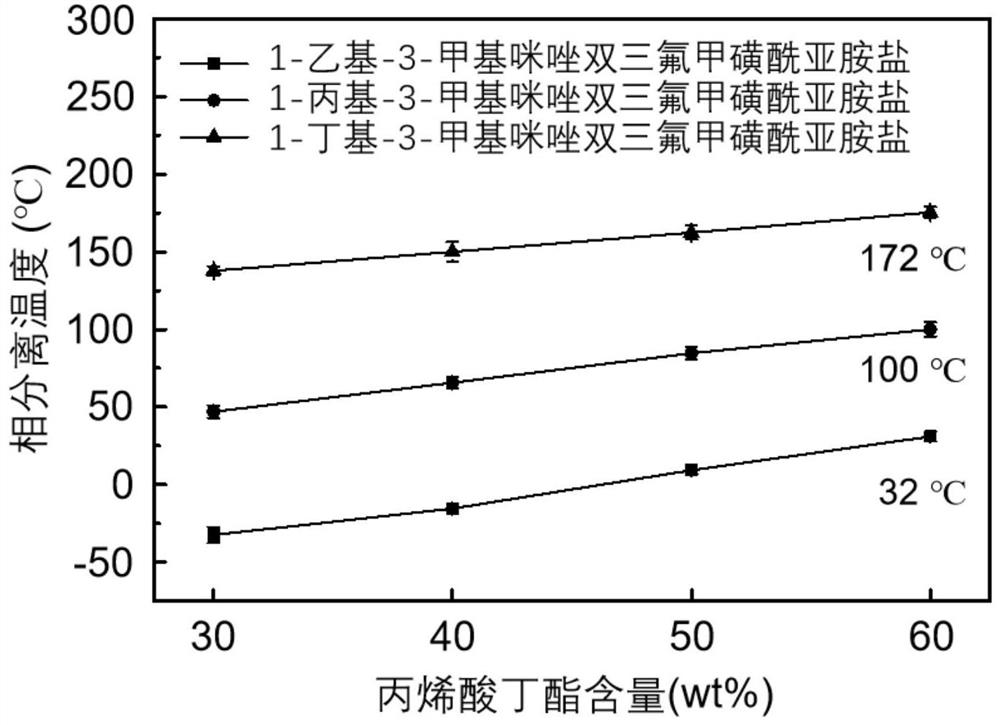

Embodiment 1

[0103] (1) Mix 0.6 g of butyl acrylate monomer and 0.4 g of ionic liquid (1-ethyl-3-methylimidazolium trifluoromethanesulfonimide salt) to obtain mixed solution A; wherein, butyl acrylate The mass ratio of ester monomer mixed solution A is 6:10;

[0104] (2) The mixed solution A obtained in the step (1) is mixed with 10 mg of ethylene glycol dimethacrylate (EGDMA for short, and the ratio of the amount of butyl acrylate monomer is 1:100) and 2 mg of 2,2-diethoxyacetophenone (ratio of 2:1000 to butyl acrylate monomer) was heated in an oven at 80°C and the solution was thoroughly mixed with ultrasound to obtain a mixed solution B.

[0105] (3) The mixed solution B obtained in the step (1) was transferred to the target mold and irradiated with ultraviolet light for 40 minutes to carry out ultraviolet light-induced free radical polymerization to obtain a heat-responsive ionic liquid gel.

Embodiment 2

[0107] The difference from Example 1 is that the ionic liquid is 1-propyl-3-methylimidazolium bistrifluoromethanesulfonimide salt, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0109] The difference from Example 1 is that the ionic liquid is 1-butyl-3-methylimidazolium bistrifluoromethanesulfonimide salt, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com