Double-seal floating disc

A double-sealing and floating disc technology, applied in packaging, large containers, transportation and packaging, etc., can solve the problems of oil immersion and oil gas leakage, volatilization, collapse, and unsatisfactory sealing effect, and achieve the effect of strengthening the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

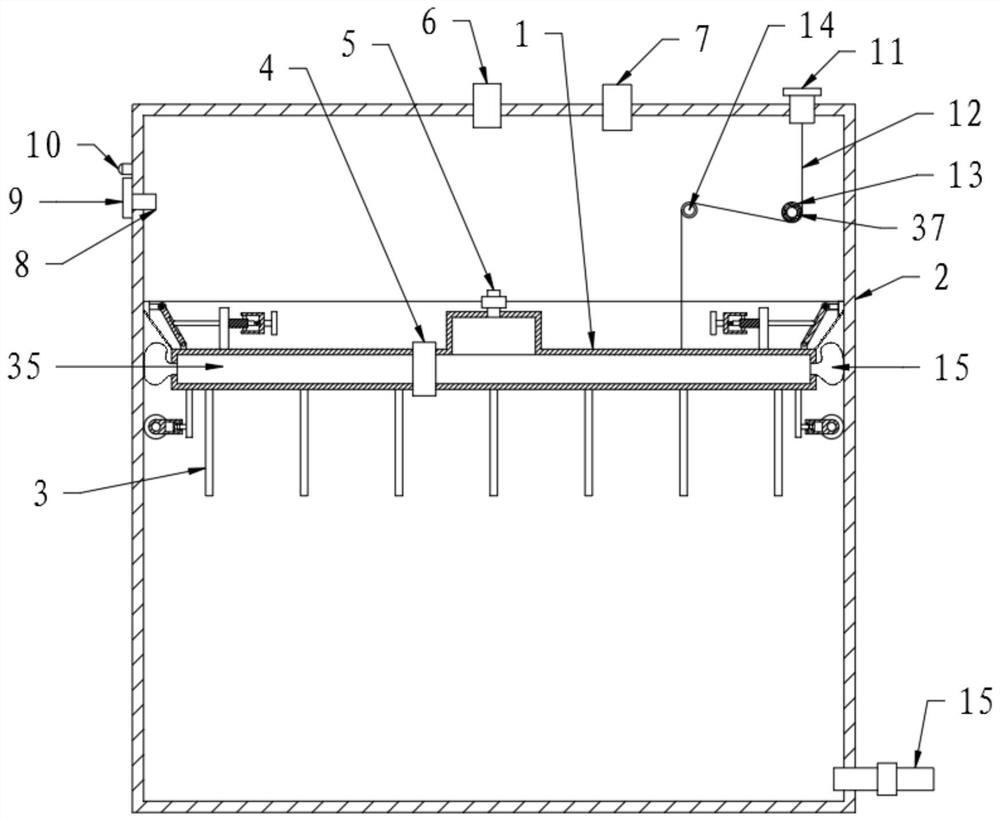

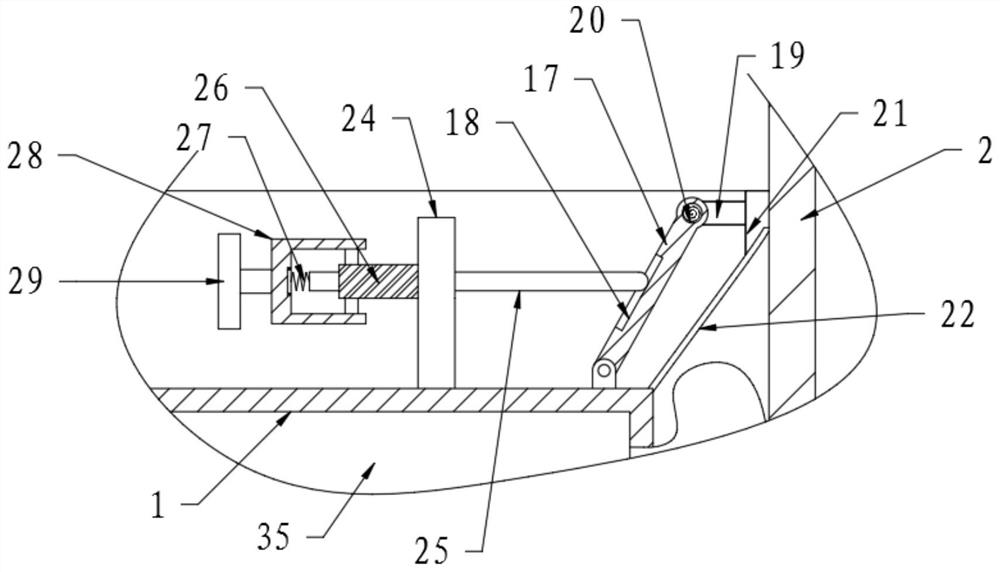

[0031] Please refer to the accompanying drawings, the present invention provides a technical solution: a double-sealed floating plate, including a floating plate 1 and an oil storage tank 2, the floating plate 1 is located in the oil storage tank 2, and the right side of the bottom surface of the oil storage tank 2 is fixedly connected with an outlet The oil pipe 16 is also provided with an air vent 6 and an oil measuring hole 7 on the top surface, and an inflation valve 5 with a valve is communicated with the middle of the top surface of the floating plate 1. The inside of the floating plate 1 is provided with a cavity 35, and the cavity 35 Airbags 15 are fixed on the edge of the periphery, and several support rods 3 are fixed on the bottom surface of the floating plate 1. Several pressure rods 17 are hinged above the top surface of the floating plate 1. A chute 18 is arranged on the inner side of the pressure rod 17, and the upper end is hinged. There is a fixed block 19, a N...

Embodiment 2

[0041] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the pressure assembly includes a lower pressure rod 23 hinged on the top surface of the floating plate 1, and the top end of the lower pressure rod 23 abuts in the chute 18, and the hinged part No. 2 torsion spring 36 is provided.

[0042] The second torsion spring 26 drives the lower pressure rod 23 to rotate downward, so as to ensure that the lower pressure rod 23 is always in contact with the chute 18 of the pressure rod 17, and ensure that the sealing block 21 and the sealing skin 22 are always attached to the oil storage tank 2 on the inner side.

Embodiment 3

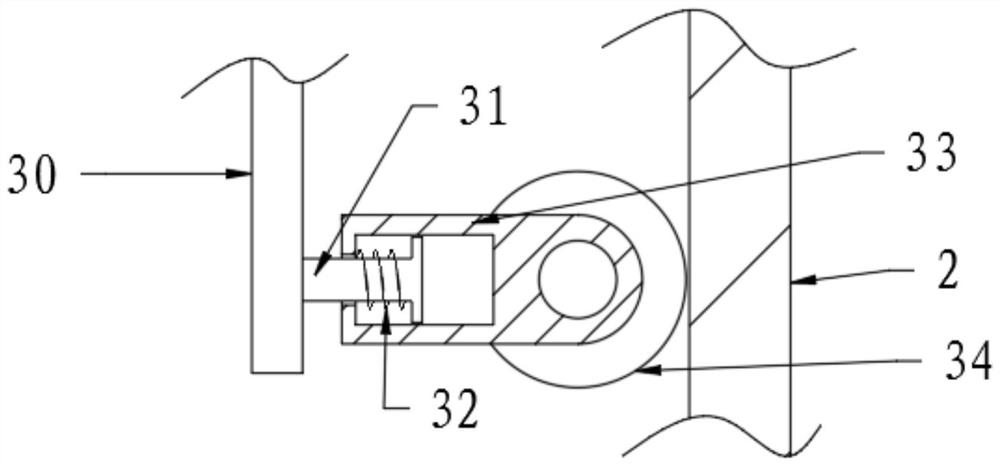

[0044] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the positioning assembly includes a protruding rod 30 fixed at the edge of the bottom surface of the floating plate 1, and a sliding rod 31 is fixed on the outer wall of the protruding rod 30. The sliding rod The outer end of 31 is slidably connected with sliding frame 33, and the end of sliding bar 31 that is positioned at sliding frame 33 is provided with No. 2 spring 32, and the outer end of sliding frame 33 is rotatably connected with positioning wheel 34.

[0045] When the floating plate 1 moves up and down in the oil storage tank 2, under the action of the No. Move up and down in the vertical direction to avoid tilting of the floating plate 1 and affect the working effect of the floating plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com