A bottom-loading boat for sintering porous metal materials

A metal porous and assembled technology, applied in the field of sintered metal porous materials, can solve problems such as crushing or fragmentation, and achieve the effects of improving stability, preventing movement and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

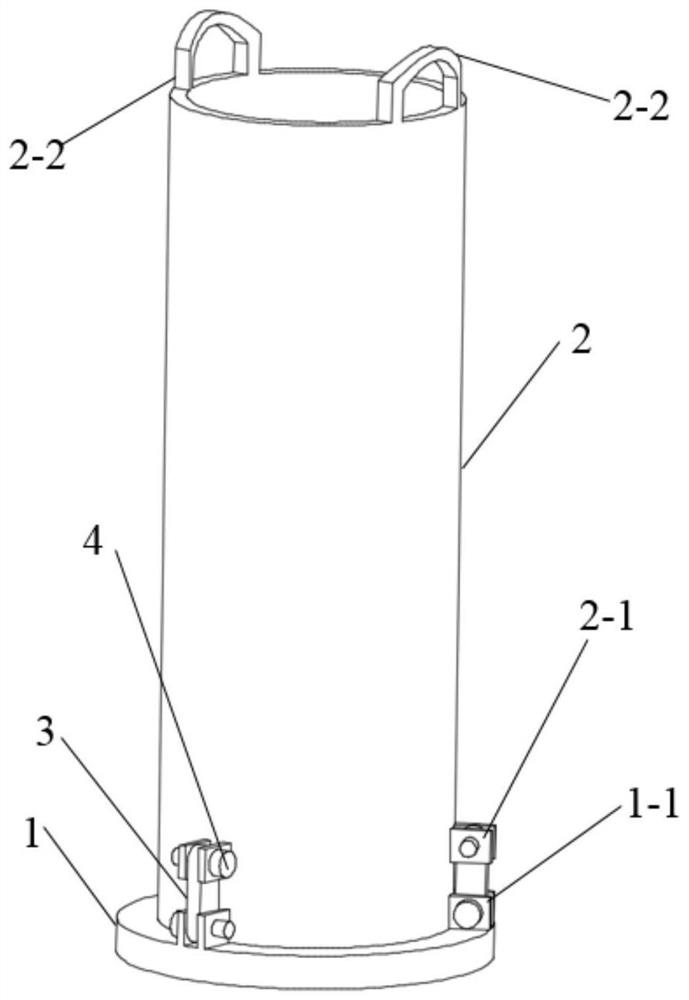

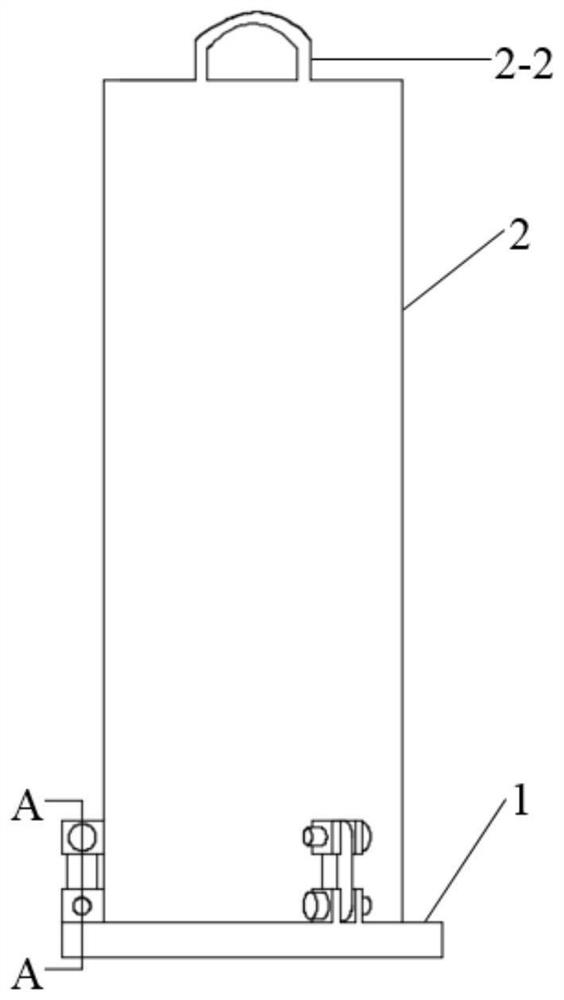

[0034] like figure 1 and figure 2 As shown, the bottom-loading material boat for sintering metal porous materials in this embodiment includes a base 1 and a boat tube 2 detachably connected to the base 1. Both ends of the boat tube 2 are openings, and the base 1 and the boat are open. A charging space is formed on the inner side of the boat barrel 2 , the charging space is used for accommodating the green porous metal material, and the charging space is used for accommodating the green porous metal material.

[0035] The existing sintering boat is generally an integrated structure of the base and the boat barrel, and the metal porous material green body is loaded into the sintering boat by loading it from the top of the boat barrel. There is a height difference between the bottom of the blank and the base of the sintering boat, which is easy to cause damage and fragmentation of the metal porous material green body after loading, especially the loading process of heavy or low...

Embodiment 2

[0045] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the base 1 is provided with an annular groove 1-2, and the bottom of the boat tube 2 is clamped in the annular groove 1-2 .

[0046] In this embodiment, the annular groove 1-2 is opened at the position close to the outside of the base 1, and the bottom of the boat tube 2 is clamped in the annular groove 1-2, so that the annular groove 1-2 is opposite to the boat tube. The bottom of 2 plays a limiting role to improve the stability of the boat 2 on the base 1, and further prevent the boat 2 and the base 1 from moving relative to each other, that is, to prevent the packing in the boat 2 from leaking out and prevent the metal porous The material blank moves in the boat barrel 2 to ensure the normal operation of the sintering work.

[0047] The working process of the bottom-loading boat for sintering metal porous materials of the present invention is as follows: place the base 1 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com