Three-dimensional dynamic column plate

A dynamic, tray technology, applied in distillation separation, chemical/physical/physical-chemical process, fractional distillation, etc., to improve the effect of gas-liquid separation, reduce pressure drop, and reduce foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

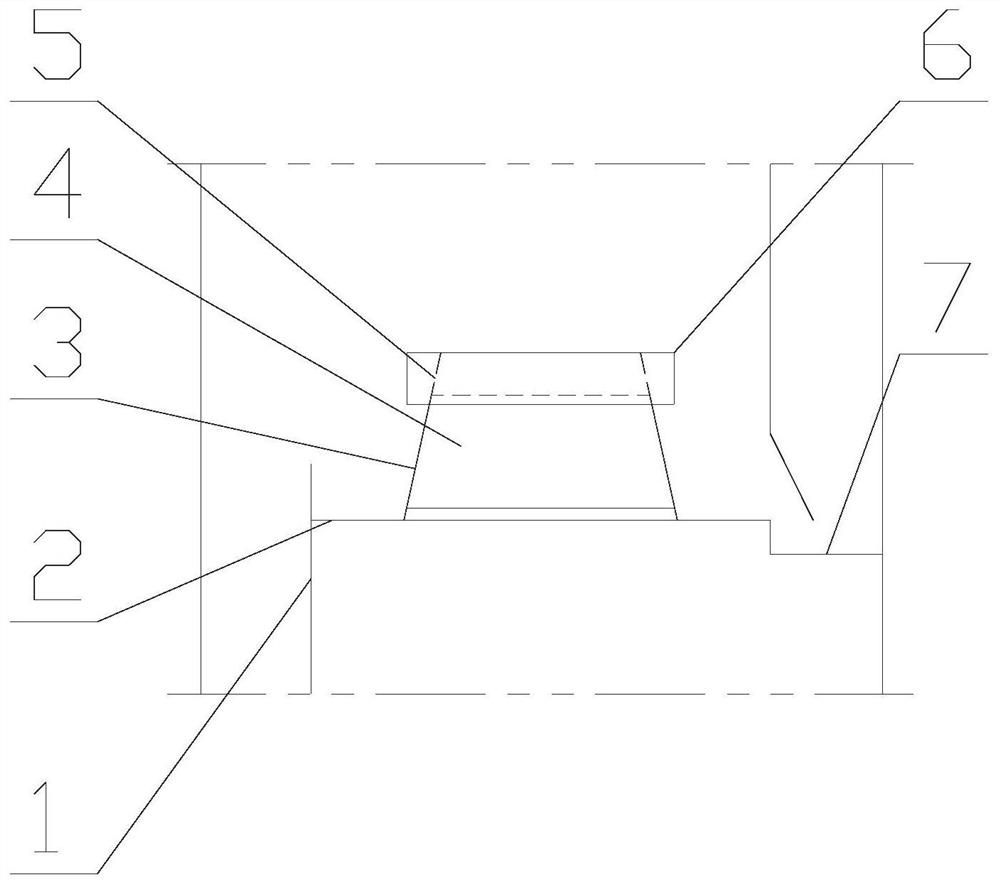

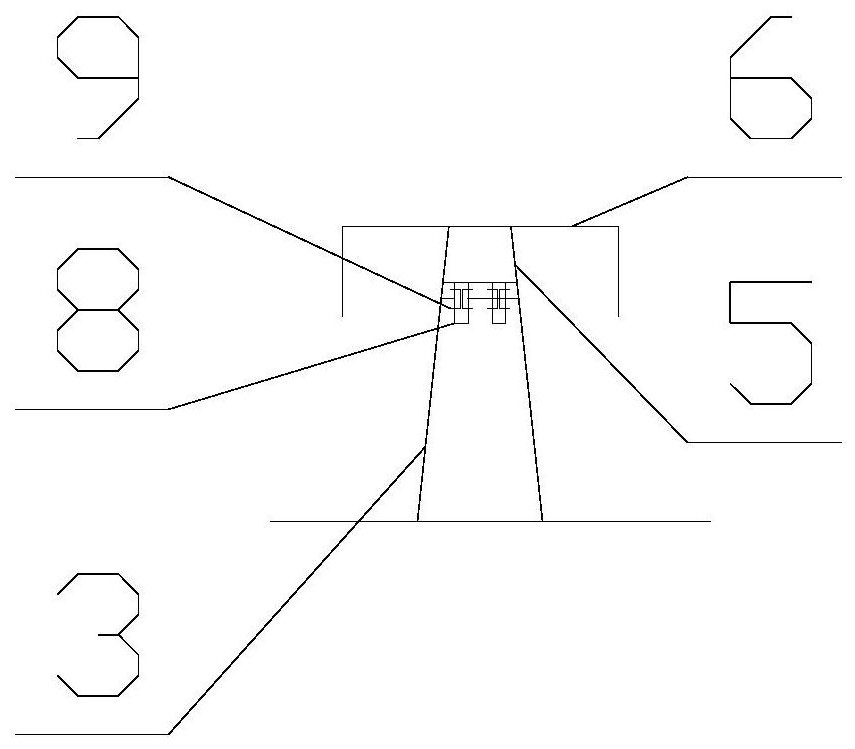

[0044] As shown in the figure, the three-dimensional dynamic tray of the present invention includes a tray 2, a downcomer plate 1, a liquid receiving tray 7 and a three-dimensional dynamic mass transfer unit installed on the tray 2, and the tray 2 is provided with a lift An air hole, the three-dimensional dynamic mass transfer unit is arranged above the air hole.

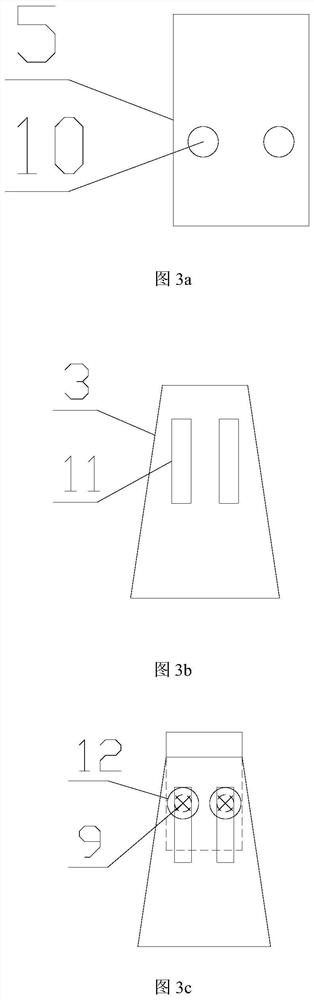

[0045] The three-dimensional dynamic mass transfer unit comprises a fixed end plate 3, a movable end plate 5, a spray plate 4 and a separation plate 6, the bottom of the fixed end plate 3 is installed on the column plate 2, the fixed end plate 3, the movable end plate Plate 5, the sides of spray plate 4 and the upper end of separation plate 6 encircle and form a spray channel, and said spray plate 4 is arranged on the side of fixed end plate 3, and said fixed end plate 3 is movably connected with movable end plate 5, so The top of the movable end plate 5 is connected with the separation plate 6, and there is an uppe...

Embodiment 2

[0055] Such as Figure 4 As shown, the three-dimensional dynamic tray of the present invention includes a tray 2, a downcomer plate 1, a liquid receiving tray 7 and a three-dimensional dynamic mass transfer unit installed on the tray 2, and the tray 2 is provided with a vent hole, The three-dimensional dynamic mass transfer unit is arranged above the air hole.

[0056] The three-dimensional dynamic mass transfer unit comprises a fixed end plate 3, a movable end plate 5, a spray plate 4 and a separation plate 6, the bottom of the fixed end plate 3 is installed on the column plate 2, and the edges of the fixed end plate 3, the movable The edge of the end plate 5, the side of the injection plate 4 and the upper end of the separation plate 6 enclose the injection channel, and the injection channel is trapezoidal. The injection plate 4 is arranged on the side of the fixed end plate 3, and the fixed end plate 3 and the The movable end plate 5 is movably connected, and the top of th...

Embodiment 3

[0063] Such as Figure 5 As shown, the three-dimensional dynamic tray of the present invention includes a tray 2, a downcomer plate 1, a liquid receiving tray 7 and a three-dimensional dynamic mass transfer unit installed on the tray 2, and the tray 2 is provided with a vent hole, The three-dimensional dynamic mass transfer unit is arranged above the air hole.

[0064] The three-dimensional dynamic mass transfer unit comprises a fixed end plate 3, a movable end plate 5, a spray plate 4 and a separation plate 6, the bottom of the fixed end plate 3 is installed on the column plate 2, and the edges of the fixed end plate 3, the movable The edge of the end plate 5, the side of the injection plate 4 and the upper end of the separation plate 6 enclose the injection channel, and the injection channel is circular. The injection plate 4 is arranged on the side of the fixed end plate 3, and the fixed end plate 3 It is movably connected with the movable end plate 5, and the top of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com