Barreled water sealing label and preparation method thereof

A technology of bottled water and sealing, applied in sealing, identification devices, stamps, etc., can solve the problems of low security and no anti-counterfeiting means for sealing labels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the bottled water sealing label, the specific steps are as follows:

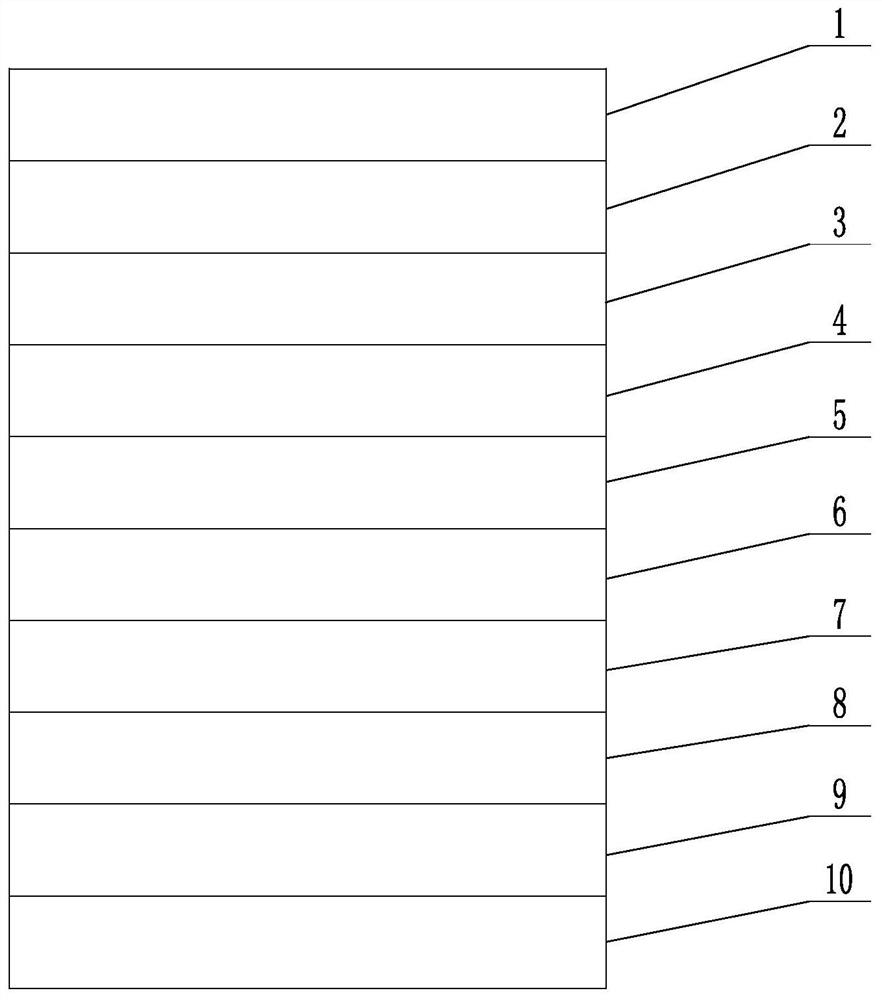

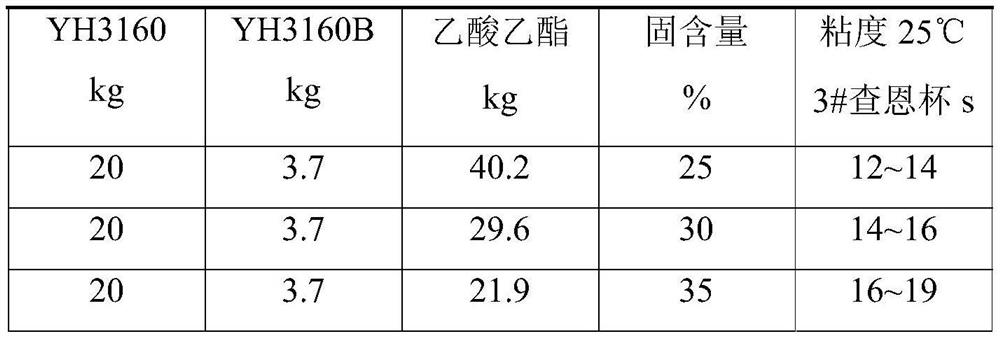

[0045] 1) Select a double-sided corona PET with a thickness of 22 μm, and use a coating machine to coat a well-proportioned coating on one side of the PET to form an imaging layer 5. The coating ratio is: FL-7202A1: FL-7202A2: butyl acetate Ester = 10:130:0.52;

[0046] 2) Use a molding and embossing gravure printing machine to mold on the imaging layer 5, copy the holographic information on the molding plate to the imaging layer 5 to form a holographic laser layer 6; then coat the holographic laser layer 6 with aluminum to form an aluminum coating layer 7 ; The square resistance value of the described aluminized layer 7 is 0.56;

[0047] 3) Utilize the secondary post-printing technology, and use a coding machine to print a variable two-dimensional code on the aluminized layer 7 to form a variable digital layer 8;

[0048] 4) Use a gravure printing machine to perform forwar...

Embodiment 2

[0069] The preparation method of the bottled water sealing label, the specific steps are as follows:

[0070] 1) Select a double-sided corona PET with a thickness of 30 μm, and use a coating machine to coat a well-proportioned coating on one side of the PET to form an imaging layer 5. The coating ratio is: FL-7202A1: FL-7202A2: butyl acetate Ester = 10:130:0.52;

[0071] 2) Use a molding and embossing gravure printing machine to mold on the imaging layer 5, copy the holographic information on the molding plate to the imaging layer 5 to form a holographic laser layer 6; then coat the holographic laser layer 6 with aluminum to form an aluminum coating layer 7 ; The square resistance value of the described aluminized layer 7 is 0.6;

[0072] 3) Utilize the secondary post-printing technology, and use a coding machine to print a variable two-dimensional code on the aluminized layer 7 to form a variable digital layer 8;

[0073] 4) Use a gravure printing machine to perform forward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com